Abstract: Chilli powder Filling is uses in packaging liquid/Powder products which are uses across various industries including pharmaceutical, chemicals, metal, plastic, agriculture, and food production. Filler offers myriads of benefits including safety of the workers and environment protection, apart from high return on investment.

Keywords: IVC1L PLC, VS07QE HMI, DA200 servo and GD10 drives

I. Introduction

Powder filling machines are automated equipment used for accurately dispensing and packaging powdered substances into containers or packaging formats. These machines are essential in industries like pharmaceuticals, food and beverages, chemicals, and cosmetics, where precise powder measurement is critical. Powder filling machines typically consist of a hopper to hold the powder, a filling mechanism, and a container handling system.

Chilli Powder Filling Machine

Total sequence: Plastic pulling, wrapping, filling, and sealing

Chilli Powder filling Servo Mounting

II. Project information and Solution

1.Project information: Chilli Powder Filling Machine

Customer demand - Chilli powder packing machine extremely improves production efficiency in packaging. Packaged chilli powder can keep its original taste and prolong storage time. Not more than 50kg of chilli powder can be packaged by chilli powder packaging equipment. Besides, sealing and cutting devices with the back seal, 3-side seal, or 4-side seal is optional. You can ask professional staff for useful suggestions so that you can choose a suitable chilli powder packaging machine.

Solution - Control Operation: System sequence is fully controlled by the timing-based systems. All the devices are having individual Off Delay and ON time. Sachet filling will be decided on the master drive speed and analog output and can be varied in the slave devices.The auger, hopper, blenders, and auger funnel make up the framework of a dry powder filling machine.

Simple operation

· Low waste Disposal.

· Easy to change for different pouch size.

· Fully automatic, Compact and Robust machine.

· With strip cutting can be adjusted even while the machine is in operation.

· Bag length can be adjusted even while the machine is in operation.

· Controlled by most advance PLC with touch screen operating panel.

· Discharge/take off conveyor system with motor.

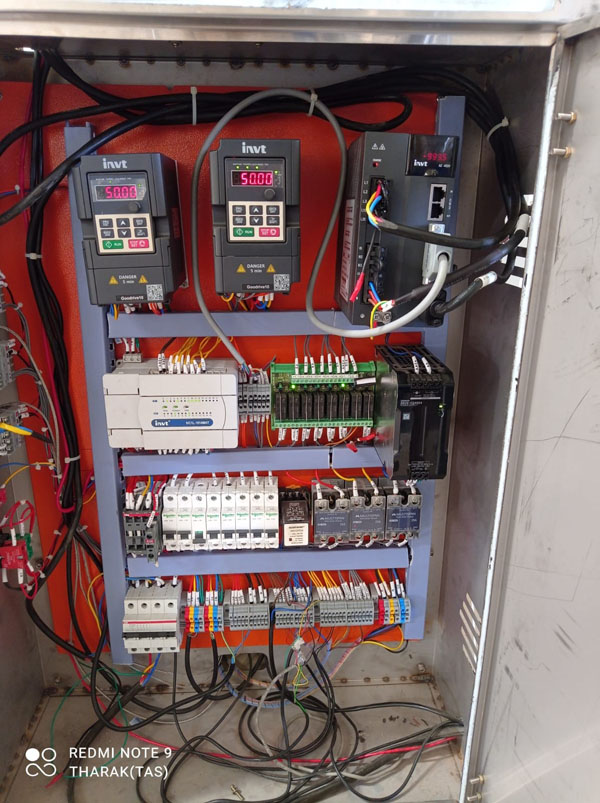

PLC and Drive mounting and wiring

2. INVT solution

| NO | Product | Qty |

| 1 | IVC1L | 1 |

| 2 | DA200-1R0-4 | 1 |

| 3 | VS07-QE | 1 |

| 4 | GD10-1R5G-2 | 2 |

3. Configurations and protocals used in system device to device for operation:

IVC1L PLC

Machine operation is controlled by the PLC, As per the logic written in the PLC.

Used ladder language for the sequencial logic development.

Servo is controlling the PLC by pulse+direction mode.

PLC to VFD RS485 communication protocol used for data read and write. ON/OFF controlling through PLC digital input and output.

PLC input and command getting thriugh the operator panel.

VS-QE HMI

PLC to HMI RS485 communication protocol used.

Data can be read and write through HMI to the PLC.

Operation process of machine can be monitored in HMI.

System alarms and IO details can be monitored in HMI.

DA200 Servo Drive

• Servo running with Pulse and direction run mode .

• Servo getting command pulse from PLC and position completing with respect to the PPR set.

GD10 VFD

Mini design VFD(<4kw)

Wall mounting done.

VFD operating through Multi step speed.

Advantages and benefits

• With high speeds that have checked and monitored the sachet production.

• Improve labour productivity. Sliding blister sealing machine packaging machinery is much faster than manual packaging. One good example of this is the candy packing machine. Here, hundreds to thousands of candies can be wrapped in minutes.

• Ensure packaging quality. Mechanical packaging is particularly important for exported goods to achieve consistent packaging.

• Handle specialized requirements, such as vacuum packaging, inflatable packaging, skin packaging and pressure filling.

III. Conclusion

A vertical form fill sealing machine is a type of automated assembly-line product packaging system, commonly used in the packaging industry for food and many other products.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.