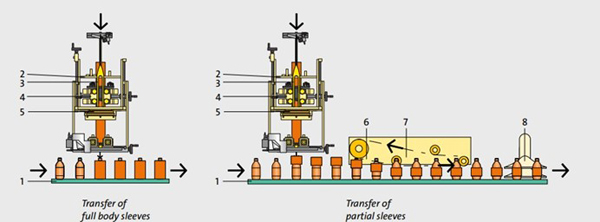

Abstract: Shrink sleeve labels are supplied from a roll in the form of a continuous web, unlabeled bottles are transported via an infeed conveyor and then metered via a rotating feed screw. While the bottles enter the labeler moving past a trigger cell, the labels in web form are opened and formed into a tube by a mandrel, fed and cut in precise registration with a printed graphic, applied to a bottle which is then conveyed up to a steam tunnel.

Keywords: AX72, E-CAM , Mark Function, DA200, Ether CAT communication, Bottle labelling, Labelling, Packaging, VS-Q HMI, INVT HMI.

I. Introduction

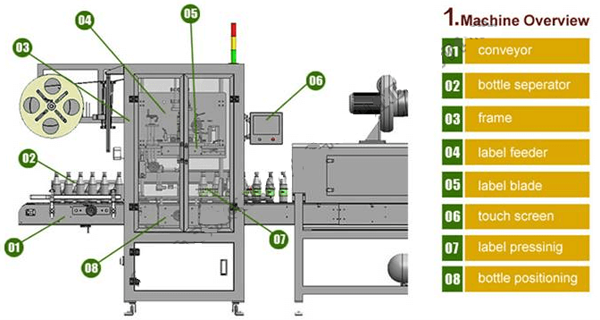

MACHINE PROCEDURE:

* The machine typically has an infeed conveyor to load products, and an exit to remove the sleeved products. The conveyor is driven by VFD. We have used GD20 VFD on V/F control to regulate the speed and speed reference on Modbus communication.

* One label unwinder is used to de-coil the label and it can be control by one clutch brake motor and this clutch brake motor can be operate from PLC based on 2 sensors.

* Label Puller/Feeder is driven by INVT DA200 servo motor which is control by AX PLC on Ether CAT communication.

* Label Blade is driven by INVT DA200 servo motor which is control by AX PLC on Ether CAT communication.

* VS-Q HMI is used to control and monitor the entire machine process. In the machine, INVT has introduced the recipe functions for different product category which helps operator to select as per his requirements.

* For mark correction we have used the advance feature and imposed it online running machine. Mark accuracy is +-1mm.

II. Project information and Solution

1. Project information

Site information: Packaging/Beverage line

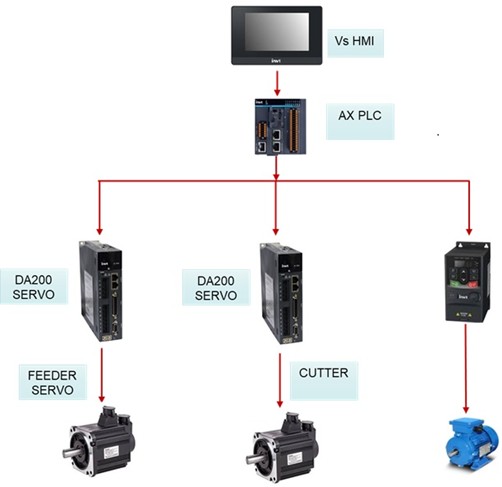

2. INVT solution

Application Name | Part code | qty | Remarks |

Controller |

AX72C-1608N |

1 |

Motion Control PLC |

Input Expansion Module |

AX-EM-1600D |

1 |

16 channel Input module |

HMI | Vs070-QS | 1 | VS-Q HMI |

INVT DA200 Servo | SV-DA200-2R0-2-N0 SV-MM13-2R0E-2-1A0-1000 | 1 | Ether CAT communication |

INVT DA200 Servo | SV-DA200-2R0-2-N0 SV-MM13-2R0E-2-1A0-1000 | 1 | Ether CAT communication |

3. Product Feature

DA200:

* Rich communication interface like EtherCAT which proivides 100 Mbps synchronization speed is used which helps to get good speed,accuracy and avoid the physical wiring.We have used the fast bus communication to achieve accurate mark correction.

* Load inertia identification: it has on-line and off-line two inertia identification mode, automatically identify the system internal gain parameters, and shorten the system adjusting time to get good response according to the load on motor shaft.

AX PLC:

* High-speed calculation capability uses the CPU with the basic command processing speed up to 1ns which helps to get less scan time and

* Supports EtherCAT motion communication to control DA200 servo with high precession.

* Advanced motion control functions to synchronization control and advanced motion control such as electronic cam, electronic gear, and positioning by using high-speed EtherCAT bus.

* MODBUS TCP/IP communication is inbuit in PLC which helps to communicate with INVT VS-Q series HMI.

VS-Q:

* Built-in COM port is integrated with RS232/422/485 communication modes

* Support industrial Ethernet communication, realize data exchange among multiple devices here we have used Ethernet modbus TCP/IP communication of HMI to communicate with AX PLC.

* High-capacity FLASH storage which helps to store more than 80 recipe,we have given upto 100 recipe of 10 data type for store the multiple program and use as per requirements.

4. System Configuration

5. System commissioning

Control panels

III. Advantages and benefits

1) Labelling with sleeves takes place without any glue application.

2) Its more efficient than start stop type application as cutter is continuously running and during feeding cutter will slow as particular degree to cut smoothly.

3) The Bottle Shrink Sleeve Machine is a high-speed application equipment used to apply label to bottles. Its speed ranges from 50 to 400 bottles per minute.

4) The system features advanced labeling systems that prevent bubbles. The machine’s improved disc label station enables it to produce smooth labels on various types of bottles using recipe.

5) Its synchronous chain mechanism ensures that the bottle is transported without bumping or jerking. Its PLC control system allows for fast and easy changeover.

6) Accuracy of sleeve mark is +/-0.5mm.

IV. Conclusion

This Sleeve Applicator is installed in packaging industry and performance, accuracy and stability all meet the process requirement. We have given INVT solution against Trio and Delta. As its 350 to 400 BPM machine so customer is very much happy with our solution.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.