Abstract: A rewinder machine is a machine that is used to wind a roll of material, such as paper, film, or tape, into a smaller roll or into a specific shape. There are several types of rewinder machines, including surface winders, center winders, and coreless winders, each of which operates slightly differently.

Keywords: Paper rewind VS Combo (Integrated PLC & HMI)

I. Introduction

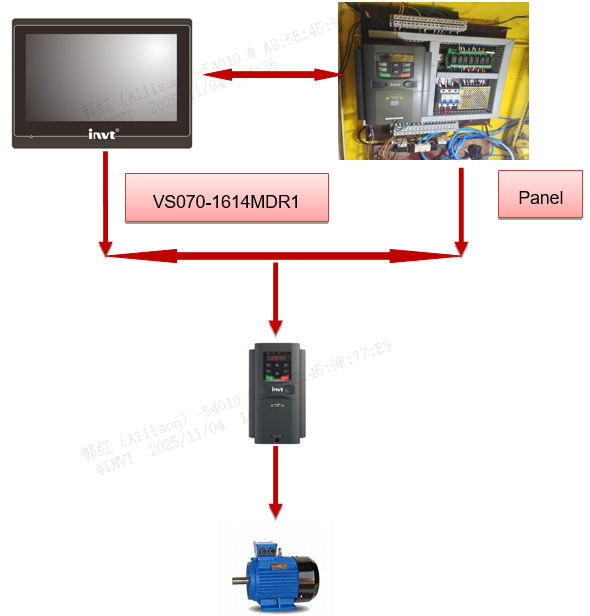

Schematic diagram of Paper Tap Rewind Machine

MACHINE PROCEDURE:-

The process for rewind the paper, film, tapes are:

• A rewinder machine consists of a series of rollers or drums that the material is fed through, as well as a drive system that rotates the rollers or drums to wind the material onto a spindle or core.

• Some rewinder machines also have additional features, such as slitting or cutting systems, to cut the material into specific lengths or widths.

• To operate a rewinder machine, the operator typically loads the material onto the machine and sets the desired winding parameters, such as the winding speed, the width of the material, and the size of the finished roll.

• The machine then winds the material onto the spindle or core, using the drive system and rollers or drums to control the tension and position of the material. Once the roll is complete, the operator can remove it from the machine and prepare it for use or storage.

Customer Needs: customer needs for paper tape rewinding machines:

• The machine should be user-friendly and easy to operate, with a clear control panel and intuitive functions.

• Automation allows for faster rewinding processes, leading to increased production output.

• Customers seek machines that can handle larger volumes of paper tape rewinding with minimal downtime.

• Automated systems integrate seamlessly into existing production lines, improving overall efficiency.

• Automation helps to minimize material waste during the rewinding process, leading to cost savings.

• Customers need the ability to adjust machine parameters (e.g., rewinding speed, tension) to suit specific needs.

II. Project Information & Solution

1. Project Information

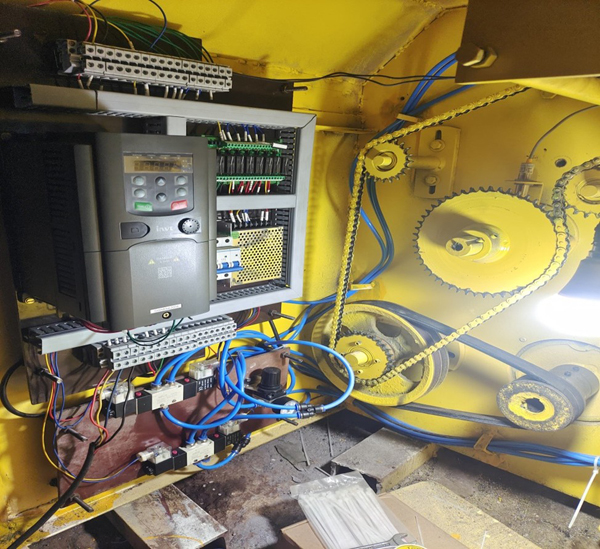

Site Information: This machine beneficial for rewind the paper, film, tapes etc.

2. INVT Solution

Application | Quantity | Inverter |

VFD | 1 | GD200A-5R5G-4 |

INTEGRATED PLC HMI | 1 | VS070-1614MDR1 |

3. System Configuration

4. System Commissioning

III. Advantages and benefits

Variable frequency drives (VFDs) & PLC having some benefits:

• Increased Efficiency and Speed: Rewinding machines streamline the process of cutting and rolling paper tape, significantly boosting production speed and efficiency.

• Reduced Labor Costs: Automation through these machines minimizes the need for manual labor, leading to lower operational costs.

• Mass Production: These machines are designed for high-volume production, allowing businesses to meet large demands efficiently.

• Precise Cutting and Rewinding: The machines ensure accurate and consistent slitting and rewinding, resulting in high-quality finished products.

• Safer Manufacturing Process: Slitter rewinders introduce a safer way to cut and roll products, reducing the risk of injuries and fatigue for workers.

IV. Conclusion

GD200A & Integrated PLC HMI is successfully used in Paper rewinding, and performance and stability all meet the process requirement.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.