1 Project background

At present, the mainstream solution of the wiring harness industry is mainly pulse control, which has the disadvantages of many wiring, complicated wiring, poor anti-interference and so on. The bus solution has great technical advantages because of its advantages of convenient wiring, beautiful wiring, fast data interaction speed, and good real-time status monitoring.

On the single-terminal terminal enclosure machine, the action axis is divided into pull spool, cutting tool axis, translation axis, clip spool, translation axis, rubber shell axis, head stripping axis, tail stripping axis, swing arm axis, twist spool and so on. The action between the axes is trivial, the position correlation is high, and there are different action choices according to different processes, which requires all processes to be realized with maximum efficiency.

2 Customer requirement

The customers require high terminal efficiency, mode switching, fast data interaction, can support stepper drive, flexible control mode, for the equipment mainly has the following requirements:

1) Any position back to the original: the equipment may stop at any process step, inevitably the position interference of various situations, the return function must be separated from the position interference that may occur in any position of any axis at any position to avoid mechanical collision and protect the safety of the equipment.

2) High-speed short stroke of the end: when the end is reached, the translation axis is fed at least 2.5mm per time, corresponding to the motor 0.125 rpm, the end is synchronized with the translation feed, and the fastest time required to hit the end is within 100ms, so the translation axis should be positioned within 100ms.

3) Multi-control mode: the device supports a variety of control mode selection;

4) Best operating efficiency: Different control modes correspond to different action requirements, and the system needs to automatically shield unnecessary actions according to different modes to improve the efficiency of the end.

5) Real-time data interaction: the operation process data can be observed online to realize the self-inspection of some core processes.

6) Good compatibility: The motion controller needs to be compatible with third-party stepper drivers.

3 INVT solution

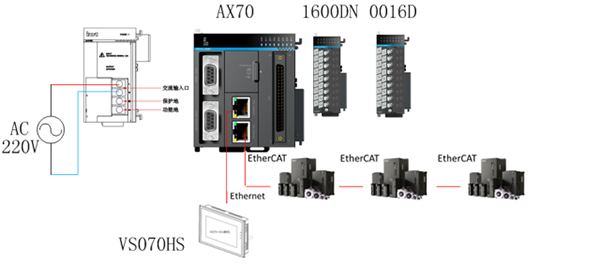

As a result, INVT launches the system solution of AX70 motion controller, DA180 servo drive and VS070 HMI:

Solution topology diagram

Product selection:

Name | Type | Qty |

AX PLC CPU | AX70-C-1608P | 1 |

PLC DI Module | AX-EM-1600D | 2 |

PLC DO Module | AX-EM-0016DN | 2 |

VK Series HMI | VK2070 | 1 |

DA180 Servo | DA180-S2R8NG0 | 6 |

Stepper | / | 4 |

The advantages of this scheme are as follows:

1) Servo drive and third-party stepper hybrid application, convenient for customers to balance cost and performance.

2) Servo high response control, to meet the end of the translation axis end stage of the high speed short stroke control requirements.

3) Codesys programming platform, rich language types, convenient to achieve customer control needs and upgrades.

4) Bus servo data reading and writing cycle ms, can easily achieve key data reading and writing, complete the core process data monitoring operation.

4 Technology solution

For the difficulties of the whole project and the realization of each process, the specific solutions of the system are:

4.1 Initialize back to the original

The principle of initialization is to be able to interfere with the position between any axes to ensure smooth return!

The servo drive adopts a 23-bit multi-turn absolute encoder, and the servo takes an absolute position of 0 during initialization. To resolve positional interference, the approximate sequence of the system is as follows:

1 | All cylinders | Reset |

2 | Delay | 300ms |

3 | Cutter axis Clamp spool Translate the axis to the safe position | Homing |

4 | Pull spool head stripping axis through rubber shell axis twist spool | Homing |

5 | Head stripping axis to safety position Pull spool | Homing |

Swing arm axis | Homing | |

Clamping of rubber shell axis | Homing | |

Wear the rubber shell axis | Homing | |

6 | Tail stripping axis | Homing |

4.2 Head stripping end process

The head stripping shaft pulls the wire skin apart and shifts the shaft main pipe end position. If the end is N harness, there are N times and N-1 spacing. The translation axis is shifted to the end position N-1 times according to the preset end spacing, and the number of ends is N. In order to improve production efficiency, the displacement and the terminal machine are started at the same time, as long as the position movement time is less than the end time. Each servo displacement is only 75ms, which fully meets the needs of the process.

In order to facilitate debugging and observation, a delay can be added before each start to observe the completion of each terminal.

Pan and hit the end of the move as: "simultaneous start - successive completion - delay - simultaneous start - successive completion - delay... ---- End".

4.3 Multi-mode switching

Considering the diversity of customer wire termination functions, the device has made a variety of mode switching, such as:

1) Tail stripping tin mode open selection;

2) Wear the rubber shell mode to open the selection;

3) End-of-line mode selection;

4) Tin dipping mode to open the selection;

5) Twist mode open selection;

6) Fault detection to open the selection;

7) Single step running mode selection.

......

4.4 Optimal efficiency process

Different modes of action timing is different, which is bound to lead to some actions do not need to be executed, at this time there will be a certain waiting time logically, reducing the operation efficiency.

The system can automatically optimize the action timing according to the actual operation mode selected by the customer, skip unnecessary waiting time and unnecessary docking location, and greatly reduce the end-of-life cycle.

In addition, the device also supports online change of the control mode, that is, the device can switch the selection function in the work project, and the system matches the current cycle or the next cycle according to the current end-of-life stage to switch modes, without stopping or returning to the original mode switch. Control efficiency is greatly improved.

4.5 Real-time data interaction

The system adopts Ethernet bus for data interaction, the data reading and writing cycle is ms-level, and the real-time data such as position, speed, torque and other real-time data observation of all axes through the synchronization cycle completes the optimization of the core process, which greatly improves the flexibility and stability of the equipment.

5 Conclusion

The terminal shell machine has a variety of processes, trivial actions, and diverse modes, which requires perfect control logic and flexible function selection. Based on the overall solution of INVT AX70 series motion controller on the terminal packing machine, not only the wiring is beautiful, the data interaction is fast, it can meet all the process needs, but also can take into account the rich control mode, flexible mode switching, high operating efficiency and other characteristics, has a strong industry promotion value.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.