Abstract: Threading machine is one of the most important applications in a CNC machine center. It is a subtractive method used in making external and internal threads of different sizes. This paper mainly introduces INVT PLC, Servo, and HMI used in this machine with high performance.

Keywords: INVT IVC3 PLC, DA200 Servo set, VS series HMI, Automatic Internal Threading Machine

I. Introduction

This machining occurs through the circular movement of a rotating tool calibrated with the required thread depth and density. The primary function of a thread is to act as a coupling agent between two mechanisms. During the coupling process, motion between parts occurs.

Machine Procedure:

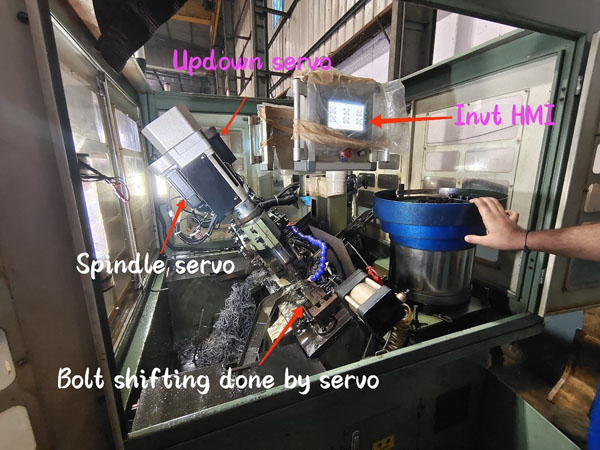

Spindle Servo: Spins the threading tool so it threads into the bolt or other parts.

Up-down Servo: Moves the spindle up and down to reach the required thread length on the bolt.

Tool Replacement Servo: Changes the completed tool with a new one through servo-controlled mechanical movement.

PLC & HMI: Controls, monitors, and transmits data from HMI to servo drive for movements.

II. Project Information and Solution

1. Project Information

Site information: Nut bolt threading manufacturing company

2. INVT Solution

In this application, internal threading is performed automatically using servo movements. Each machine includes 3 DA200 Servo sets, 1 IVC3 PLC, and 1 QE HMI. A total of six machines were deployed.

| Product | Model No. | Qty | Application |

|---|---|---|---|

| PLC | IVC3-1616MAT-4 | 6 | Controller |

| HMI | VS070QE | 6 | Controller |

| Servo Drive | SV-DA200-E0 (400W, 750W & 3KW) | 18 | Spindle, Up-down & Tool Replacement |

3. System Features:

A) All settings can be changed through the HMI – very convenient operation.

B) Cost-effective components ensure high return on investment.

III. System Commissioning

Control panels were tested and configured as part of the commissioning process.

IV. Advantages and Benefits

• High production efficiency due to automatic operation.

• Data can be easily input and monitored through the HMI screen.

• Easy fault detection.

• High accuracy threading with servo drives.

V. Conclusion

INVT offers a cost-effective and reliable solution, successfully operating in India with customer satisfaction.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.