Abstract: This paper mainly introduced INVT IVC1L PLC, VS07 HMI and DA200 servo used in surface grinding machine application with full-closed loop control. The full-closed loop control can greatly improve the production quality and accuracy by using feedback and correlation between measuring device and manufacturing device.

Keywords: Surface Grinding Machine, Full-closed loop control, INVT Servo, PLC, VS HMI

1. Introduction

Surface grinding is a finishing process that uses a rotating abrasive wheel to smooth the flat surface of metallic or nonmetallic materials to give them a more refined look by removing the oxide layer and impurities on work piece surfaces. This will also attain a desired surface for a functional purpose.

Surface grinding Machine

The machine consists of a table that traverses both longitudinally and across the face of the wheel. The longitudinal feed is usually powered by hydraulics, as may the cross feed, however any mixture of hand, electrical or hydraulic may be used depending on the ultimate usage of the machine (i.e., production, workshop, cost). The grinding wheel rotates in the spindle head and is also adjustable for height, by any of the methods described previously.

Closed-Loop Application

* Application program introduction

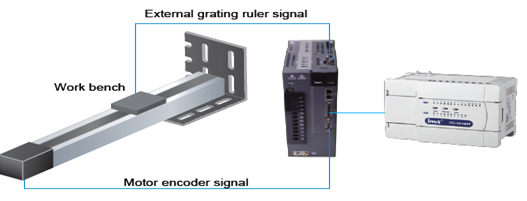

The difference between full closed-loop and semi-closed loop servo system:

Semi-closed loop refers to the CNC system issues instructions, servo receives and then performs instructions, and the servo encoder itself feedbacks position to servo in the implementation process. The servo itself corrects the deviation to avoid deviation, but the mechanical error cannot be avoided, because the CNC system does not know it.

Full closed-loop refers to the servo receives instructions and then implements it, the location feedback device on mechanical device will direct feedback to CNC system in the implementation process. Through comparison, CNC system judges the actual deviation and sends command to servo, correcting the deviation.

* Important part of full closed loop - grating scale:

Grating scale, also known as grating scale displacement sensor, is a measuring feedback device that utilizes optical principle of grating. It is often used in closed-loop servo system of precision machines for linear or angular displacement detection. The output signal is digital pulse, with large detection range, high accuracy, and fast response.

2 Project Information and Solution

* Project information:

The machine continuously produces stable quality sutures and ensures cost-effective production in multi-shift operation. During machine operation, needles can be loaded in bulk and products unloaded without interruption. Only thread spool or product variant changes require a standstill.

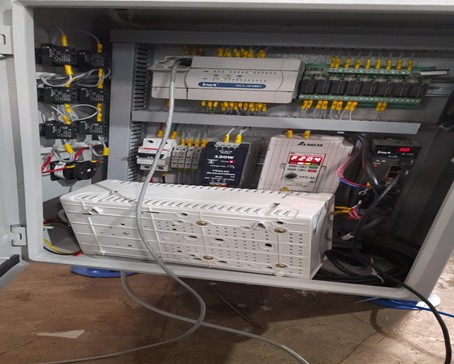

PLC mounting and wiring

* INVT solution:

| S.N | Product | Qty | Remark |

|---|---|---|---|

| 1 | SV DA200-1R0-4 | 1 | High accuracy driving |

| 2 | IVC1L PLC | 1 | Control unit |

| 3 | VS07-QE | 1 | Display and control |

* Solution features:

A) Support grating scale installed in the external load side to achieve full closed-loop control, reduce the impact of mechanical transmission backlash, and ensure terminal positioning accuracy.

B) Directly measure external load travel; effectively overcome transmission error caused by mechanical wear.

3. Advantages and Benefits of Closed Loop System

• Servo Position is controlled by PLC, and values can be set via HMI.

• Position accuracy, speed, and spins are set by operator.

• Operational in single and continuous cycles.

• Superior Surface Finishes that meet demanding specifications with high accuracy and efficiency.

4. Program Summary:

a) Repeated positioning accuracy is controlled within 2um.

b) Compared with semi-closed loop systems, full closed-loop avoids uncertainty caused by long-term mechanical wear.

c) DA200 benefits from full closed-loop control in accuracy, flexibility, and high-speed response, enabling it to challenge imported servo brands.

5. Conclusion

All PLC, HMI, VFD and servo components are successfully used in this surface grinding application. Processes, performance, accuracy, and stability all meet requirements. Total of 4 machines installed and tested within a week.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.