Abstract: Liquid filling machines are equipment used for packaging of various liquid products, mainly food and cold drinks. Nozzle liquid filling machine is a type of liquid filling equipment designed to dispense liquid into multiple containers simultaneously depending upon the nozzles. Its allowing for efficient and rapid filling of multiple containers at once. These machines are commonly used in industries like food and beverage, pharmaceuticals, and cosmetics to fill bottles, jars, and other containers with various types of liquids.

Keywords: TS600, DA180, Ether CAT communication, Position control, Beverages, Bottle filling, Packaging, VS-Q HMI, INVT HMI,INVT motion, TS PLC

I. Introduction

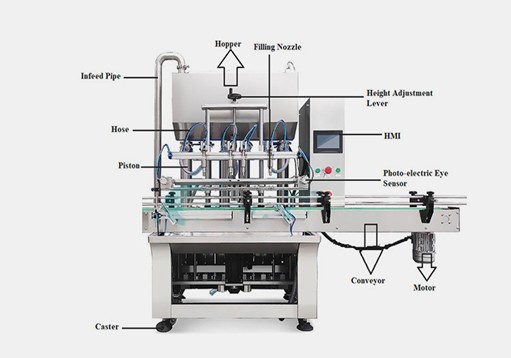

MACHINE PROCEDURE:

* The machine typically has a conveyor to load products(Bottles), and an exit to remove the filled products. The conveyor is driven by VFD. We have used GD27 VFD on V/F control to regulate the speed and speed reference on Modbus communication.

* 4 nozzles are mounted on machine, which are open and close by pneumatic solenoid valve and its based on time so the filling quantity can be calibrated as per time and its control by TS PLC.

* Nozzles up and down move by INVT DA180 servo which help to no overflow and accurate filling of liquid into the bottles

* INVT DA180 servo motor which is control by TS633 PLC on Ether CAT communication.

* VS-Q HMI is used to control and monitor the entire machine process. In the machine, INVT has introduced the recipe functions for different product category which helps operator to select as per his requirements.

II. Project information and Solution

1. Project information

Site information: Packaging/Beverage line

2. INVT solution

Application Name | Part code | qty | Remarks |

Controller |

TS633 |

1 |

Motion Control PLC |

HMI | Vs070-QE | 1 | VS-Q HMI |

INVT DA100 Servo | DA180-S2R8SG0 IMS20A-06M40B30C-2-P9 | 1 | Ether CAT communication |

GD27 VFD | GD27-2R2G-S2-B | 1 | Ether CAT communication |

3. Product Feature

DA180:

* Rich communication interface like EtherCAT which proivides 100 Mbps synchronization speed is used which helps to get good speed,accuracy and avoid the physical wiring.We have used the fast bus communication to achieve accurate mark correction.

* 23 bit encoder gives high resolution so get precise linear movement.

* Load inertia identification: it has on-line and off-line two inertia identification mode, automatically identify the system internal gain parameters, and shorten the system adjusting time to get good response according to the load on motor shaft.

TS PLC:

* High-speed calculation, which helps to get less scan time

* Supports EtherCAT motion communication to control DA180 servo with high precession.

* Advanced motion control functions to synchronization control and advanced motion control such as electronic cam, electronic gear, and * MODBUS TCP/IP communication is inbuit in PLC which helps to communicate with INVT VS-Q series HMI.

VS-Q:

* Built-in COM port is integrated with RS232/422/485 communication modes

* High-capacity FLASH storage which helps to store more than 80 recipe,we have given upto 100 recipe of 10 data type for store the multiple program and use as per requirements.

GD27:

* Heavy load design, 150% 1min, Support SM and AM motor, Built-in brake unit standard,Save space, Vector control

* Used modbus communication to change the frequency so on change on the speed.

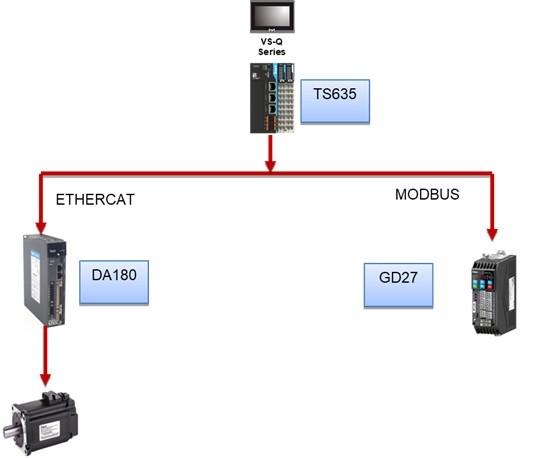

4. System Configuration:

5. System commissioning

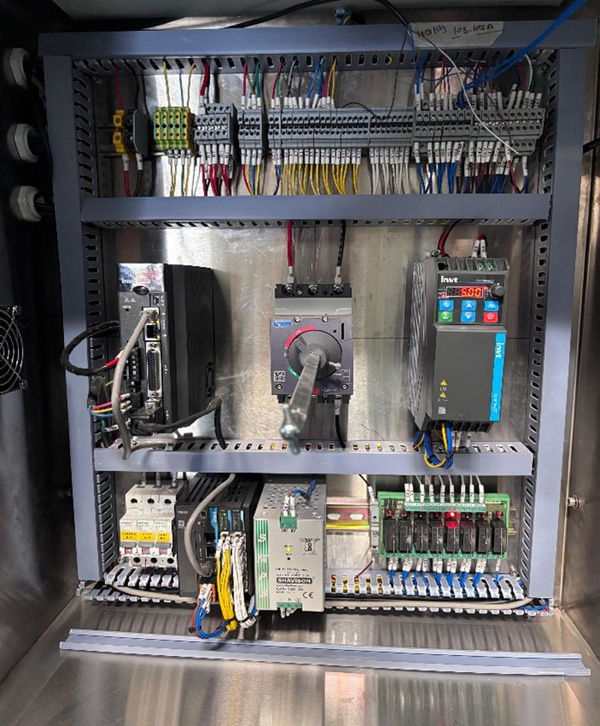

Control panels

III. Advantages and benefits

1) A 4-nozzle liquid filling machine with servo and PLC offers several advantages, including enhanced efficiency, increased accuracy, flexibility, and lower labor costs, simultaneous filling of multiple containers, significantly boosting production speed.

2) Servo motors provide precise control over filling, ensuring accurate fill volumes and minimizing waste. Individual head monitoring via PLC allows for fine-tuning and optimization of the filling process for each nozzle.

3) We got the filling accuracy of ±2-3% and get a speed 8 small bottle per minute and 3 big bottle per minute.

4) Ether CAT communication has used which leads to remove the physical wiring and troubleshooting is easier.

IV. Conclusion

Liquid filling machines is installed in packaging industry and performance, accuracy and stability all meet the customer requirement. We have given INVT solution against delta DVP. As we have given economical solution with EtherCAT communication so customer is very much happy with our solution.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.