Abstract: The basic components of electrical cables are the conductor, generally drawn wires made from copper, aluminum or alloys, and the insulation. A cable usually features a specific cross-section containing numerous wires. If taken individually, however, the wires would be too fragile and might break. Therefore, they are grouped to form flexible conductors. The finer the wires, the more flexible the conductor.

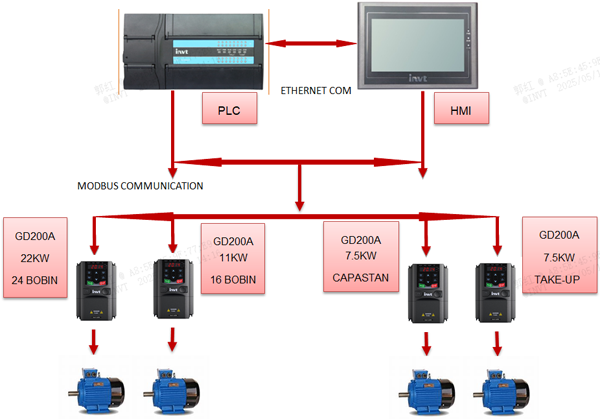

Keywords: GD200A VFD on Modbus Communication with PLC & HMI on Ethernet Communication.

1. Introduction

Schematic diagram of wire twisting making process

* PLANT PROCEDURE:-

The process for making cables and conductors involves several steps, including:

• Strictly abide by various operating procedures to ensure safe production.

• According to the lay length requirements specified by the process, install the corresponding pulleys and lay length gears according to the lay length table.

• Install the pay-off reel, and pull the aluminium wire through the wire storage of the pay-off rack to the wire inlet end of the host, and then pass into the host through the guiding input. One of them must be guided by the meter counter.

• Install the take-up reel, and the wire passing through the host will pass through each guide and twist the bow, and finally wind a few turns on the take-up reel.

• Turn on the main power switch in the electric cabinet of the host, and set the length budget of the meter counter according to the process requirements. If the original length of the original meter is not zero, it should be cleared.

• Check whether the tray at the bottom of the main unit has been lowered to the end. If it has not been lowered to the end, loosen (turn it counterclockwise) the switch of the oil pressure pump to lower it to the end, and close the door and cover.

• When the predetermined length is reached, the cable twisting machine will automatically stop. After the twisting bow is completely stopped, you can open the hood and lower the unloading door. Then turn off the oil pump switch (rotate clockwise), pull out the oil pump hook, and squeeze the oil pump handle to raise the tray to support the take-up reel. After unloading the spool, in order to prevent the hydraulic handle from falling off, hook the hook to the handle of the oil pump.

• During operation, if any disconnection is found, the machine will automatically stop emergency. If an unexpected situation occurs, you can press the "Emergency Stop" button when you need an emergency stop, and the machine will stop quickly.

• When wire breakage or wire change occurs, the connector should be small and reliable. Before the joint reaches the take-up reel, it should run at low speed. At this time, the jog mode should be used. The jog operation method is as follows: open the door cover, press the micro switch with your left hand, and press the "inch button" with your right hand, the bow will run at low speed. Release this button to stop running. The joint should be checked visually during the inching process. After the joint reaches the take-up reel, the door cover can be covered and the normal operation can be changed.

Twisting machines consist of a body, spindle, and circuit parts that twist multiple single wires into a single strand. The machines are suitable for twisting various materials like copper, alluminium. They work by twisting wire cores into one strand and reduce noise interference in audio and network cabling applications.

* Customer Needs

Customers want to upgrade the panel as they are getting the low production or low accuracy in manual operation.

Their needs are:

• To improve the quality of material.

• High production and accuracy.

• Upgrade panel because they wants to see how much wire is passed in meter as final production.

2. Project Information & Solution

* Project Information

Site Information: The plant area where wires are twisting.

* INVT Solution

Product | Model No. | Qty. | Application |

PLC | IVC3-1616MAT | 1 | CONTROLLER |

HMI | VS-102HCS | 1 | OPERATING PANEL |

VFD | GD200A 7.5KW | 1 | CAPASTAN |

VFD | GD200A 7.5 | 1 | TAKE-UP |

VFD | GD200A 22KW | 1 | 24 BOBIN |

VFD | GD200A 11KW | 1 | 16 BOBIN |

* Features used in this solution

• VFD and PLC are in Modbus communication and HMI PLC are in Ethernet communication easy to used and control.

• Start and stop from HMI with high speed.

• Customer can easily watch the Ampere, RPM & Frequency of all VFDs.

• When VFD trips on fault, HMI having a Window pop-up to show the fault of that particular VFD.

• They can easily use Jog mode for filling the Aluminium wire in Bobin.

* System Configuration

* System Commissioning

3. Advantages and Customer benefits

• High Production Efficiency: These machines can produce large quantities of cables rapidly, minimizing downtime and maximizing output.

• Precise Control: Advanced settings allow for precise control over conductor size, insulation thickness, and overall cable dimensions, leading to consistent quality.

• Versatility: Most cable and conductor machines can be adapted to produce various cable types, from power cables to communication cables, with simple adjustments

• Reduced waste: Precise manufacturing minimizes material waste, leading to cost savings.

• Improved Quality: Consistent production parameters ensure high-quality cables with reliable performance.

• Large Volume capability: These machines can handle large production volumes, suitable for large-scale projects.

• Automation: Automation features streamline the production process, reducing human error and increasing efficiency.

• Cost-Effectiveness: By optimizing production and minimizing waste, cable and conductor machines can be cost-effective

4. Conclusion

IVC1L PLC Ethernet communication with HMI which is high responding communication and GD200A VFD are Modbus communication with PLC. Used in wire twisting processes, and performance and stability all meet the process requirement. High accuracy and High production meets the product of INVT.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.