Background

With the rapid development of science and technology, the speed of product iteration is accelerating, and traditional manual production lines can no longer meet such rapidly changing needs. Automated production lines have become the first choice for modern manufacturing due to their advantages of improving production efficiency, ensuring product quality and consistency, and reducing costs. As the key link in the automated production line, the performance and stability of the loading and unloading manipulator directly affect the operating efficiency of the entire production line.

Customer requirements

Faced with increasingly fierce market competition, customers have put forward higher requirements for the performance of automated production lines:

* Solve the problem of uneven material placement: When the existing manipulator places materials, the gaps are of different sizes, which easily cause materials to fall and affect production efficiency.

* Improve production speed: Customers hope to further improve production speed to meet the market demand for fast delivery.

INVT solution

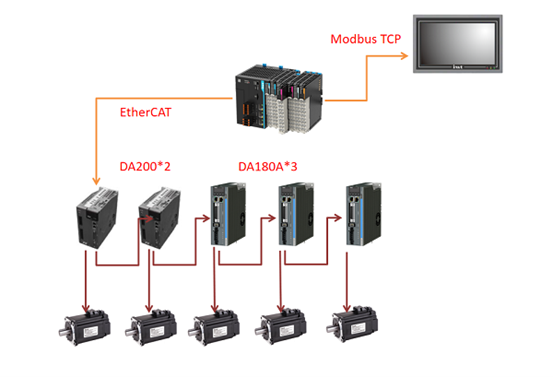

In order to meet the urgent needs of customers, INVT launched a full EtherCAT bus control system based on VS-Q series HMI + TM700 series PLC + DA200 servo + DA180A servo. The system uses electronic cams to achieve precise control of the master and slave axes, combined with advanced algorithm compensation and optimized action logic, thereby greatly improving the discharge accuracy and production speed, meeting many demands such as diversification, fast delivery, and cost reduction.

Solution advantages

. Precise material grabbing and placing: Compared with traditional solutions, INVT system can accurately grab and place materials within the range of online speed from low speed 2m/min to high speed 20m/min, with stable operation and excellent performance.

. Strong compatibility: adopting the full cam system solution + automatic compensation algorithm, the beat speed of the whole machine can be automatically adjusted according to the speed of the production line. There is no need for customers to adjust the speed of each axis separately, which greatly saves the machine adjustment time.

Customer benefit

Quality improvement: The material discharge gap error is reduced from the maximum uneven 1.5mm to an even 0.5mm, which effectively solves the problem of material falling and improves product quality.

Beat improvement: The maximum speed increased from 18m/min to 20m/min, further improving production efficiency

Efficient debugging: high and low speeds are automatically adapted, and there is no need to adjust parameters in groups. Servo parameters can be conveniently set directly through the host computer, and batch import and export are supported, which greatly improves the debugging efficiency.

Safe and reliable: When problems occur during manual operation, the system can automatically stop the Y and Z axes in a safe position and wait for the abnormality to be resolved; if problems such as axis alarms occur, the entire machine will stop running immediately, effectively avoiding safety hazards such as collisions.

Summary

With its extensive product line, INVT has achieved remarkable results in automated production lines in various industries. This time, TM700 successfully solved the problems of uneven material placement and production speed improvement in automated production lines. Through the advantages of precise material grasping and placing, strong compatibility, efficient machine adjustment, safety and reliability, it has brought significant production benefits to customers. In the future, INVT will continue to increase its R&D efforts, continue to be committed to technological innovation and product upgrades, provide customers with more high-quality and efficient automation solutions, and contribute to the intelligent development of the manufacturing industry.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.