Abstract: A pick and place machine is an automated system designed for the precise handling and placement of components in manufacturing processes or in packaging industry. These machines enhance efficiency and increase the rate of packing by reducing man power. Here new launched INVT product TS600 series small PLC installed. This has excellent data processing capability and efficient data transmission speed.

Keywords: DA180, VS HMI, Ether CAT, TS PLC

1. Introduction

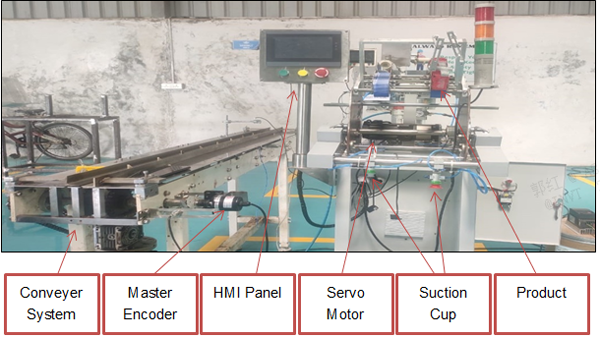

Machine Procedure:

* Control System:

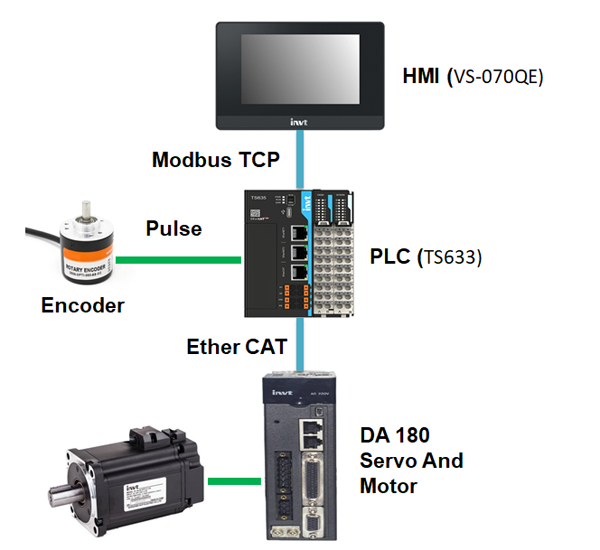

1. PLC and HMI interface to visualize the operation and control the system.

2. Servo drive and PLC communicated though Ether CAT communication for better response.

3. For precise pick and drop use master encoder on conveyer side, with the help of master encoder servo rotate 0 -180 deg.

4. Provide different operation mode like Online and Offline.

a. Online: Servo rotates with the help of master encoder.

b. Offline: Servo rotates without encoder feedback.

* Rotating system:

1. Servo motor runs in precise, high speed, 0-180 deg.

2. 0 deg. for material pick and 180 deg. for material drop on conveyer system.

* Pneumatic based pushing system:

1. System provided to push automatic material forward

2. Provide 2 systems to increase the rate of packaging.

3. Pushing cylinder trigger with help of job present sensor. If job present sensor not available then pneumatic cylinder operate ON/OFF with define time delay.

* Suction Cup:

1 Provide 2 suction cups to pick and drop material at a time.

2. It operates at particular degree which is settable on HMI screen.

3. Due to this material drop in precise location.

2. Project information and Solution

* Project information

Site information: Packaging Industry

* INVT solution

Product | Model No. | Qty. | Application |

PLC | TS633 | 1 | CONTROLLER |

HMI | VS-070QE | 1 | CONTROLLER |

SERVO DRIVE | DA180-S4R5NG0 | 1 | ROTATRY |

SERVO MOTOR | SV-ML08-0R7G-2-SA0-1000 | 1 | ROTATRY |

* System Configuration

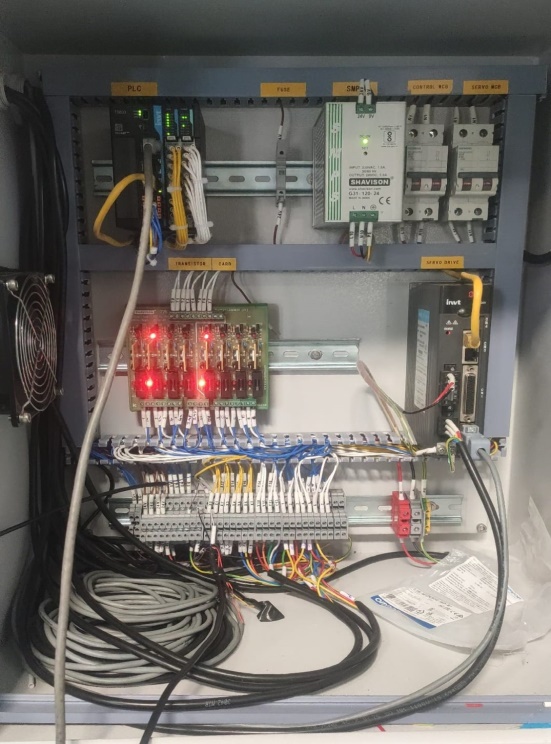

* System commissioning:

Control panel

3. Advantages and benefits

* Easy programming and monitoring

* Due to double pick and drop increase the packaging speed.

* 120 packets can pick and drop per minute.

* Reduce wait times by streamlining the process.

* Due to compact size of machine, easily place anywhere.

* Operating voltage is 230VAC, so can easily install in non-commercial area also.

* With automated pick and place, cycle times are shorter as the machine operates at a consistent and high speed without breaks.

* These machines offer high precision, ensuring that every part is picked up and placed exactly where it is needed, leading to consistent product quality.

* Automated machines can replace manual labor, leading to significant savings in wages and training.

* By replacing manual labor in tasks that may be repetitive or physically demanding, these machines reduce the risk of workplace injuries.

4. Conclusion

This pick and drop machine is installed in packaging industry. Due to master encoder and servo meet the accuracy, performance and stability. We have given INVT solution against Delta and Omron controller.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.