Background

With the rapid development of automation and intelligent technology, the traditional manual incense industry has also begun to change. As the core equipment for the automated production of various incense products (stick incense, coil incense, bamboo stick incense, etc.), incense machines have replaced traditional manual operations with mechanized and intelligent technologies, greatly improving production efficiency and product quality. In an increasingly competitive market environment, incense machine manufacturers need to continuously upgrade equipment performance to meet the market's demand for higher output, more stable quality and more flexible production.

Customer Request

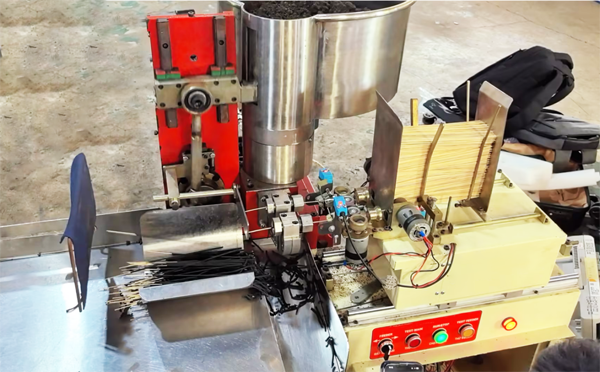

A large incense making machine manufacturer in Vietnam decided to upgrade the original single-mouth incense making machine and develop a double-mouth equipment to adapt to market changes. The original single-mouth equipment used the INVT GD20-BK model, but the double-mouth incense making machine has a more complicated process, and the customer put forward a series of strict new requirements:

* The acceleration accuracy is required to reach 0.01s to ensure the accuracy of motion control during the incense making process and to guarantee the molding quality of the incense products.

* It needs to have the characteristics of high dynamic response and stable performance, and be able to maintain stable operation during high-speed production to avoid production failures and quality problems.

Integrate the incense making process logic to make the process flow smoother, reduce equipment debugging and maintenance time, and improve production efficiency.

* Increase production to meet the needs of large-scale production and improve market competitiveness.

* Integrated DC motor drive and DC motor protection function to extend the motor life and reduce equipment operating costs.

INVT Solution

In response to the strict requirements of customers, INVT launched the GD28-BK multi-terminal inverter solution based on GD28 drive. This solution has the following features:

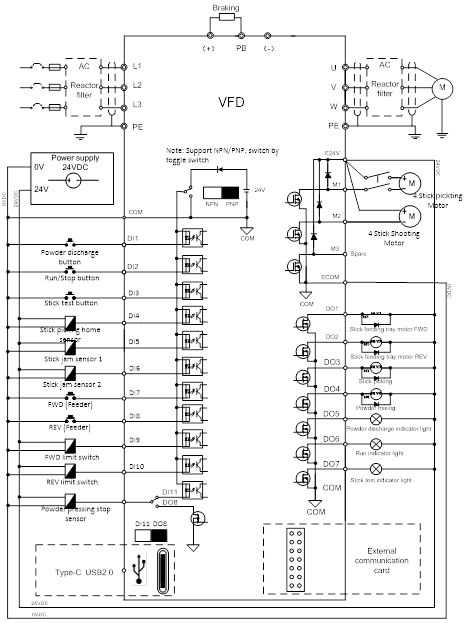

* Rich terminal configuration: integrated with 11 digital inputs (DI), 8 digital outputs (DO), 2 M mos DC motor control terminals and hardware protection circuits, it can meet the complex control requirements of the double-mouth incense making machine and achieve precise control of each production link.

* Process integration: The control panel integrates the incense making machine process, without the need for additional PLC, which simplifies the system structure, reduces costs, and improves the reliability and stability of the system.

* Wide voltage input adaptability: With wide voltage input characteristics, the bus voltage range is 150 - 400V, which can adapt to the low-quality power grid input environment in the Vietnamese market and ensure that the equipment can operate stably under different power grid conditions.

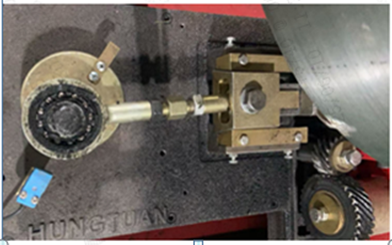

* Sensorless fixed parking position: A special algorithm is used to remove the parking position sensor signal to achieve sensorless parking, reduce the impact of sensor failure on production, and improve equipment reliability and maintenance convenience.

* Flexible output adjustment: The output can be adjusted according to different frequencies, and the maximum output can reach 580pcs/min - 590pcs/min to meet the needs of customers in different production scenarios.

Customer Benefits

* Cost saving: Due to the integrated process logic, there is no need to use PLC, and customers save the cost of purchasing PLC and the related system integration and maintenance costs.

* Motor protection and cost reduction: Integrated DC motor control terminals and hardware protection circuits effectively reduce damage to DC motors, reduce maintenance costs and downtime, and improve the comprehensive utilization of equipment.

* Improved production stability: When the sensor signal is unstable, the inverter can automatically fine-tune to maintain the equipment rhythm, ensure the continuity and stability of production, and reduce production failures and quality problems caused by signal problems.

* Advantages of sensorless shutdown: Special algorithm realizes sensorless shutdown, simplifies equipment structure, reduces failure rate, and improves equipment reliability and maintenance efficiency.

* Increased output: The maximum output can reach 580pcs/min - 590pcs/min, which is a significant improvement compared to the original single-port equipment, enhancing customers' competitiveness in the market.

Conclusion

In the dual-channel incense making machine project, INVT GD28-BK special machine fully met the customer's strict requirements with its excellent performance and customized solutions. The adaptability of the inverter software control has been fully tested, and the system configuration fully meets the requirements of on-site use. The successful application of this project not only reflects INVT's rapid response capability and technical strength in customized development, but also provides a reliable solution for the automated production of the incense making industry. In the future, INVT will continue to uphold the concept of innovation, provide customers with more high-quality products and services, and promote the automation and intelligent development of the industry.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.