As SPS 2025 opened its doors in Nuremberg on 25 November 2025, INVT made a strong statement with a 148-square-meter booth showcasing its latest industrial automation, network energy, and solar storage solutions. The exhibit quickly became one of the show's major talking points.

Germany remains the heartland of Industry 4.0, and INVT arrived ready to meet the market's exacting standards. At Hall 1, Booth 1-324, the company presented a full-stack automation portfolio—drives, PLCs, servo systems—enhanced with AI capabilities designed to push manufacturing toward greater efficiency, intelligence, and reliability.

Beyond automation, INVT also highlighted its complete data center infrastructure lineup alongside solar inverters and energy storage solutions. With data and energy forming the backbone of modern industrial automation, these offerings ensure stable, efficient, and sustainable power for industrial equipment.

New Product Highlights: Faster, Smarter, More Flexible

* GD28 Series General-Purpose Drives–Designed for diverse applications and rapid integration, these drives significantly reduce commissioning time while adapting seamlessly across industrial environments.

* GD350A High-Performance Drives– Built on INVT's latest Euler software platform, the GD350A delivers enhanced motor control, improved parameter adaptability, and greater ease of use.

* TP2000 Series Controllers–The new TP2000 compact multi-axis controller supports up to 128 axes, features built-in visualization and EtherCAT real-time networking, and represents a major leap in integrated motion control—purpose-built for Europe's most demanding manufacturing environments.

* DA360 AC Servo System–Delivering high speed, precision, and comprehensive safety protection, the DA360 includes multi-function expansion modules and holds CE certification along with other international approvals, ensuring smooth global deployment.

Industry-Specific Solutions:From Components to Complete Lines

Drawing on extensive field experience, INVT showcased tailored solutions for printing and packaging, fluid machinery, corrugated board production, logistics and warehousing, metallurgy, and solar-powered pumping systems. Each solution reflects real-world implementation experience, helping equipment manufacturers boost quality, increase throughput, and accelerate their digital transformation journey.

Live Demo Systems: Hands-On, Immersive Experience

The booth featured several interactive demo systems that let visitors experience INVT technology firsthand:

* TP2000 Synchronization & Ring Redundancy Demo–Using direct-drive gantry modules and dual-axis servos, this setup demonstrated real-time synchronization and redundant operation, highlighting the precision control capabilities of the new TP2000 platform.

* Data Center Infrastructure Demo–Showcasing INVT's highly integrated and customizable all-in-one solutions for small server rooms, large-scale data centers, and outdoor deployments.

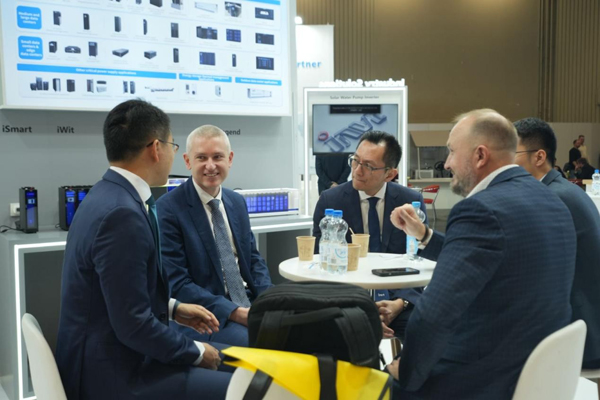

Visitor traffic remained strong throughout the opening days, with European customers and prospects engaging INVT's technical team in detailed discussions about product capabilities, application cases, and industry trends. Live streaming and prize draws added extra energy to an already bustling booth.

SPS is a key platform for INVT to deepen its presence in the European market. With a global service network of over 180 authorized service centers and more than 800 channel partners, INVT continues to deliver comprehensive solutions in industrial automation and energy management to customers worldwide.

INVT invites machine builders, system integrators and end users to visit Hall 1, Stand 1-324 at SPS 2025 to explore how its latest technologies can help build smarter, more efficient and more sustainable industrial control systems.

Facebook

Facebook

Twitter

Twitter

Google+

Google+

LinkedIn

LinkedIn

Prev

Prev