According to the latest statistics, China’s wind power industry maintained rapid growth in the first half of 2024, with newly installed capacity reaching 25.84 million kilowatts and a cumulative grid-connected capacity of 467 million kilowatts. China continues to lead the world in wind power capacity, and under the drive of technological innovation, the industry is showing diversified development trends.

Wind power generates electricity by converting wind energy into mechanical energy, serving as a strategic measure to combat climate change and promote green, low-carbon development. INVT has joined forces with customers to innovate and develop a pure electric four-wheel-drive coil car specialized for wind power applications. Powered by a speed-increasing gearbox driving the generator, this solution has become an important choice in the global energy transition.

As a key part of clean energy, wind power plays a critical role in China’s energy structure adjustment and in achieving the “dual carbon” goals, injecting new momentum into industry development.

Equipment principle

The wind turbine blades are installed horizontally. During installation, the first blade is positioned and secured in a horizontal orientation. Then, the four-wheel-drive coil car system drives the blade to rotate 120° to the second installation position. After completing the installation of the second blade, the system synchronously drives the two blades to rotate another 120° for the installation of the third blade.

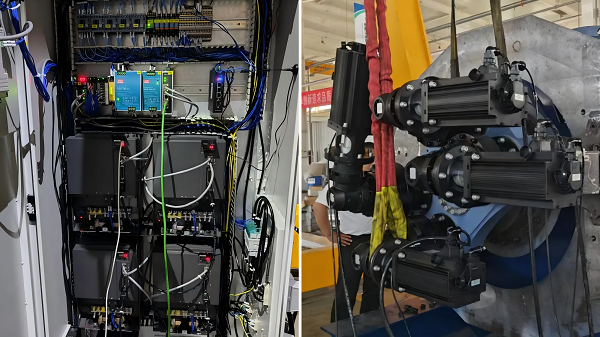

This four-wheel-drive coil car system is coordinated by four servo motors, which precisely control the blade rotation to the specified angles, ensuring installation accuracy. The entire coil car operation is efficient and stable, taking only 25 minutes per cycle, significantly improving installation efficiency.

INVT solution

INVT launched the DA200-N0 series servo system solution, featuring reliable electromagnetic compatibility design and superior quality. The upper-level PLC uses real-time torque feedback from the servos and employs a PDI torque distribution algorithm to control the torque balance among the four servos in real time.

The four servos communicate with the upper-level PLC via the highly interference-resistant EtherCAT bus, with a synchronization cycle of 1 ms, ensuring fast and reliable command and data exchange between the servos and the PLC.

Customer benefits

1. High responsiveness: The DA200 series servo features a speed response frequency of up to 2.0 kHz. Coupled with a 23-bit high-resolution encoder, the servo system can quickly adjust to external changes, enabling rapid tuning and ensuring smooth rotation speed of the wind turbine blades.

2. High reliability: With excellent overload capacity, the instantaneous torque can reach up to three times the rated torque. This means the servo system can handle sudden heavy loads, easily overcoming the inertia impact of large wind turbine blades.

3. High safety: The servo motors are equipped with electromagnetic brakes to ensure safe and reliable coil car operation. In case of temporary pauses or unexpected power outages during the four-wheel-drive coil car operation, all four brakes engage simultaneously to lock the coil car’s position, preventing free swinging caused by blade center of gravity imbalance.

As a vital pillar in the global energy transition, the wind power industry enjoys broad prospects and profound significance, driven by both technological innovation and policy support. With advances in technology and cost optimization, INVT will fully leverage its technical strengths to continuously enhance the operational efficiency and reliability of wind power systems through innovative products and solutions. This will inject strong momentum into the transformation of the global energy structure and sustainable development, propelling the wind power industry toward a more efficient and intelligent new phase.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.