Abstract: IPE300 series engineering inverter is a high-performance closed-loop vector single drive inverter designed and developed based on engineering application requirements. Based on industrial application environment, it improves product reliability, ease of use, maintainability, environmental adaptability, and has the advantages of high power density, rich functions and flexible application configuration. It can be widely used in nonferrous metals, metallurgy, papermaking, petroleum, chemical industry, HVAC and water supply, municipal, electric power, building materials, power supply and other equipment driving with high reliability and high performance requirements. This article is dedicated to present our IPE300 had been used in high-speed spindle applications successfully.

Keywords: IPE300, High-speed spindle, Valve drive, KTY84, PTC, PLC, CNC.

Overview

INVT’s IPE300 series frequency drive provides a variety of expansion cards for customers to choose from, including PG card, communication card, I/O expansion card, etc. each inverter can be equipped with up to three expansion cards at the same time. PG card supports incremental, resolver, sine/cosine and other common encoders, and all support pulse setting and frequency division output; it adopts digital filtering technology to improve electromagnetic compatibility and realize long-distance stable reception of encoder signal; it has the function of detecting encoder line break to avoid expanding the influence of system fault.

Support Modbus, CANopen, PROFIBUS-DP, PROFINET, EtherCAT and other international mainstream field-buses communications, seamless docking of upper computer and DCS control system.

Introduction of field application

At present, one of Germany factories in China wants to replace the Lenze inverter on the high-speed grinder with the INVT inverter, and has realized the control function with IPE300 inverter. The subsequent replacement is successful, then the customer will replace all Lenze inverters with INVT IPE300 engineering inverter. INVT has made non-standard software for customers to meet the application requirements on site, and complete the matching test with Siemens PLC.

Here below are the pictures showing all kinds of CNC devices in the factory.

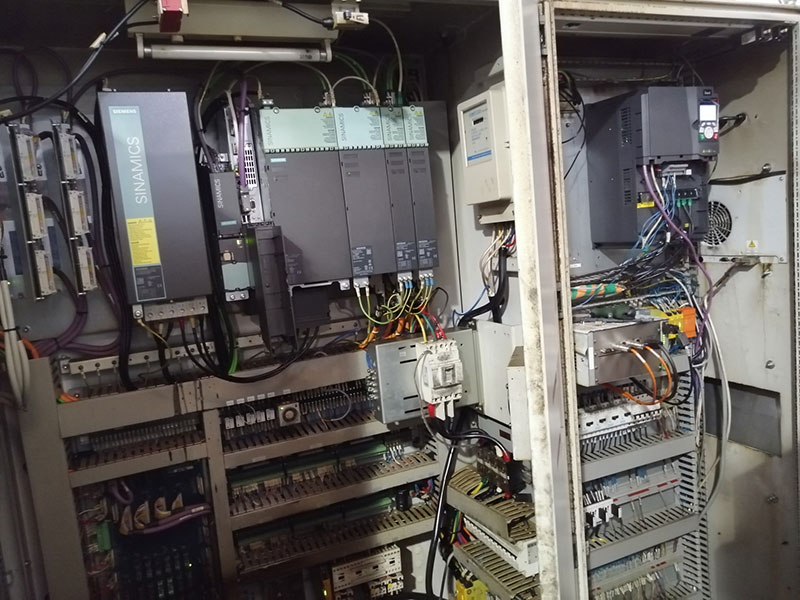

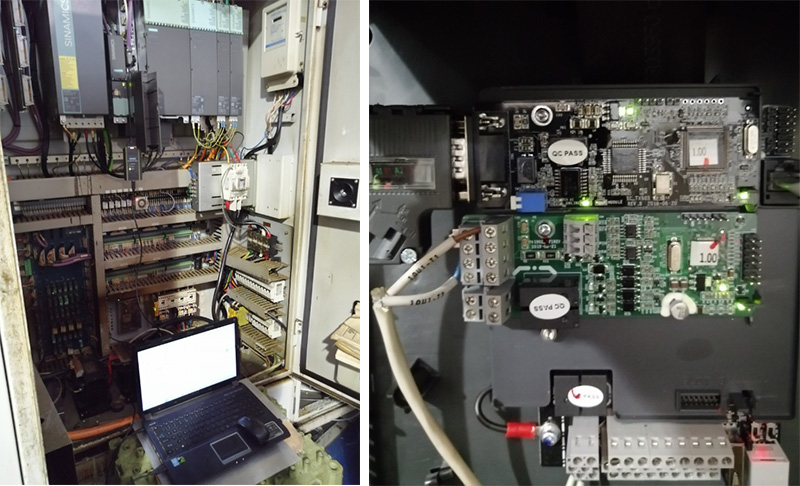

Siemens CNC pictures as below:

Siemens PLC and LENZE Inverter’s pictures as below:

The Application is mainly for grinding semi-finished products, the products as below picture for reference:

Introduction of INVT solution

INVT according to customer’s providing special requirements, provide the perfect

control solution. Below picture is about INVT IPE300 replaced Lenze VFD successfully.

Customers’ requirements

1. IPE300-037G-4 inverter needs to separate control power supply and main circuit power supply. However, it is better to supply 24 V

power separately for subsequent supply, because the control power of the equipment reconstructed on site is 24 V, and 220 V needs to be

separately led to power supply, which is very inconvenient.

------INVT’s solution: Realization of 220 V auxiliary power supply through

non-standard hardware design.

2. The original motor temperature detection is PTC, require inverter can support, and the relevant temperature protection parameters

can be set.

------ INVT’s solution: It can connect PTC through AI/AO analog terminals, simulate PTC temperature protection of motor.

3. IPE300 needs to equipped with LCD keypad, which is convenient for customers to use and maintain.

------IPE300 Series can provide

LCD keypad.

4. The motor temperature detection is PTC and KTY84. We hope that INVT inverter can use both, and the relevant temperature protection

parameters can be set.

------Customized the FW to make AI/AO available for supporting PTC and KTY84 function, reduce the cost of adding

an optional I/O card.

New features of INVT’s IPE300 solution

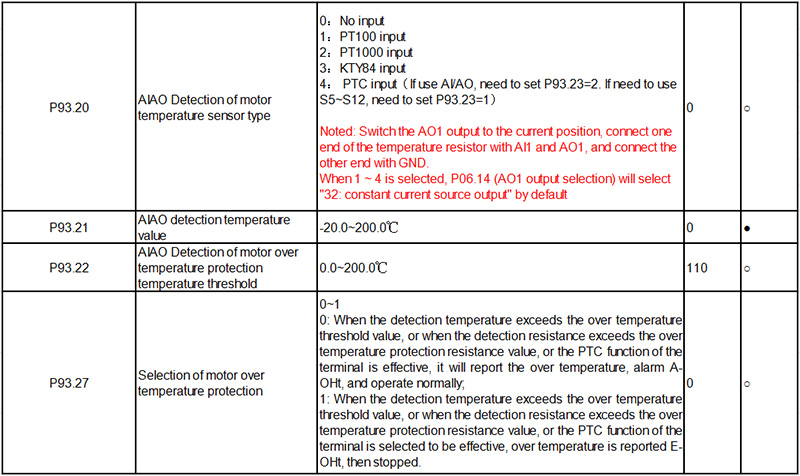

(1) Newly added KTY84 over temperature protection (similar settings for PT100 and PT1000)

a. P93.20 = 3, using AI/AO detection for

protection.

b. Switch the AO1 output to the current position, connect one end of the temperature resistor with AI1 and AO1, and connect

the other end with GND.

c. When the temperature detected by P93.21 is greater than the over temperature protection threshold value of

P93.22, the over temperature protection action is set according to P93.27.

New parameters:

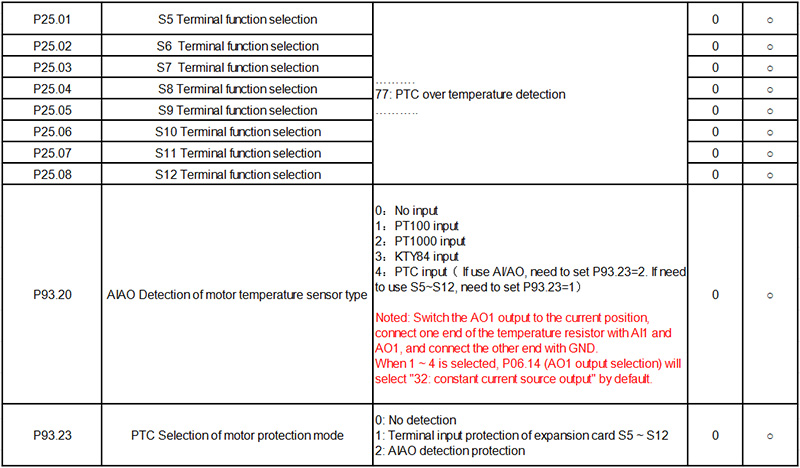

(2) New PTC motor temperature protection

The first kind: input terminal protection

a. P93.20 = 4, P93.23 = 1, input protection with expansion card S5 ~ S12 terminals,

b. At this time, it is also necessary to configure any terminal function in S5 ~ S12 as "77: PTC over temperature detection"

c. When the terminal input signal is valid, the over temperature protection action is set according to P93.27.

New parameters:

The second kind:

a. P93.20 = 4, P93.23 = 2, using AIAO detection for protection

b. Switch the AO1 output to the current position, connect one end of the temperature resistor with AI1 and AO1, and connect the other end

with GND

c. The default output of p93.24 is 4.000mA (according to the change range of PTC actual resistance value with temperature, multiply P93.24,

it can not exceed 10V)

d. When the resistance detected by P93.26 is bigger than the over temperature protection threshold value of P93.25, the over temperature

protection action is set according to P93.27.

New parameters:

Commissioning Procedure

VFD parameters setting:

Notes: IPE300 default is NPN, customer require PNP, so S1 is high-level, PW connect external 0V.

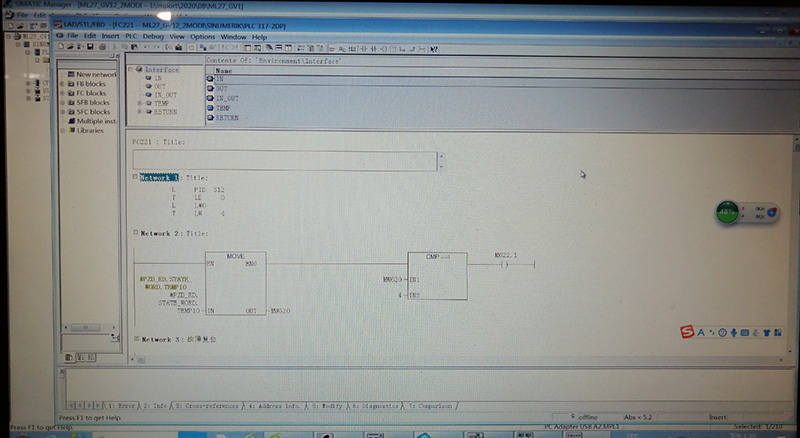

Siemens PLC programming:

Summary

After the testing in the application site, we had used IPE300 in high-speed spindle applications successfully. It can support detecting different kinds of motor protection resistors. And support STO functions, IPE300 communicated with Siemens PLC by Profibus-DP communication, had successfully replaced Lenze inverters.

References

[1] GD350 Inverter Operation Manual. Shenzhen INVT Electric CO., LTD.

[2] IPE300 Inverter Operation Manual. Shenzhen INVT Electric CO., LTD.

[3] Siemens PLC operation manual. Siemens.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.