Abstract: Four-edge embossing is a relatively high-grade production process for drawing paper. This paper introduces the four-edge embossing process of automatic paper stacking line realized by INVT AX controller and Good drive350 inverter.

Keywords: AX controller, Goodrive 350, paper stacker, four-sided embossing

1.Preface

Embossing is to make the surface of the paper more beautiful, in addition to increase the friction between the thin paper of a single sheet of paper, improve the integrity of the paper, so that the user can easily pick up the whole use, not to produce a single layer of separation. Embossing is done by using embossing rollers. Commercially available drawers usually have patterns printed on only two sides, with the embossing rollers turning to the side and parallel to it being blank. Four-sided embossing improves the aesthetics of a single sheet of drawer paper, while conforming to the aesthetic concepts of traditional handkerchief and square-towel designs.

2.Mechanical Structure Introduction

Embossing roller: Embossing roller is driven by main motor through synchronous belt. Mechanical calculation of good reduction ratio, a pattern corresponds to all knives.

2. Embossing traction roller: responsible for conveying paper into the embossing roller, traction roller and embossing roller speed ratio to form a certain traction tension.

3. Hydraulic compression device: The paper is pressed by the pressure of the compression device against the embossing roller to produce the pattern.

4. Knife device: through the point device to adjust the embossing roller out of the paper to cut the length of the knife paper, to achieve the paper can just cut in the center of the cross-press.

3. Solution

Embossing traction rollers and hydraulic compression devices are realized by electrical control, while embossing rollers and knife setting devices are realized by mechanical adjustment.

1. Embossing traction roller control

The embossing traction unit achieves precise tension control through the closed-loop vector position control of the INVT GD350 series inverter. It maintains a fixed tension without paper breakage no matter in acceleration or deceleration state.

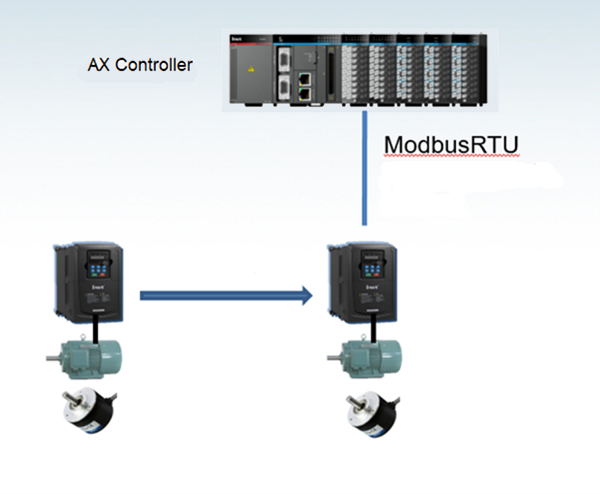

Since the embossing roller is bound to the speed of the main knife axis by the timing belt, the position signal of the main inverter is extracted here as the given position of the embossing traction axis. The electronic gear ratio is modified by communicating with the embossing inverter through the serial port of AX controller. The tension control is realized.

2. Pressing device control

The pressing device is driven and controlled by an oil pressure station. The control requirement is to reach the set pressure before operation, and to be able to make up the pressure automatically if the pressure is not enough. When the spindle is stopped, the pressing device should be backed off to prevent paper breakage.

The oil pump station has two sets of solenoid valves to control the forward and backward of the two pressing devices. The oil pump motor generates oil supply pressure, and in general, the oil pump motor cannot be turned on and off frequently.

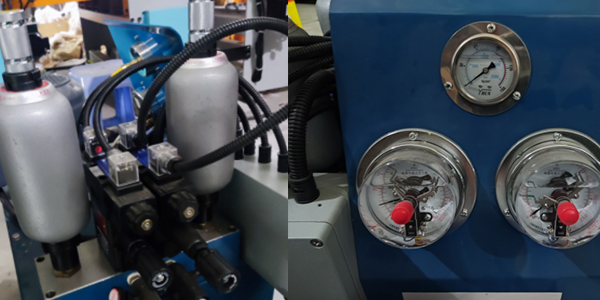

There are three gauges on the pressure control panel, the top one is the oil supply pressure, the oil supply pressure should be adjusted to be larger than the set pressure, otherwise it will not reach the set pressure. A larger pressure setting can reduce the pressure arrival time and start-up time. However, it should not be set too large to prevent too much pressure overshoot.

The following two tables show the pressure of two sets of compression rollers, and the set pressure can be adjusted by the red knob. When the pressure roller reaches the set pressure, it will automatically close the oil inlet valve. When the pressure is not enough, the inlet valve can be opened again automatically. The gauge head provides a pressure arrival signal contact, and the system will judge the pressure arrival according to the contact feedback signal, whether the main machine can start operation.

There are two capsule accumulator tanks next to the solenoid valve, which can refill the oil cylinder and prevent frequent opening and closing of the valve caused by oil leakage.

4. Conclusion

It has been tested by customers to achieve clear embossing effect at various speeds, and the paper will not be broken even after acceleration and deceleration and stopping, so it is worth promoting vigorously.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.