1. Introduction

The laminating machine is a special equipment for paper and film, among which the pre-coating laminating machine is small in size, low in cost and flexible and convenient in operation. The lamination processing of small batches and scattered printed matter has great development potential.

However, some pre-coating laminating machines currently on the market still have inaccurate spacing between papers and large deviations, resulting in unsatisfactory laminating effects.

2. Customer needs

In the coating and laminating machine of a machinery company in Shantou, the customer reported that the previously developed system was not ideal and hoped to improve the disadvantages. Its main requirements are:

1. The paper feeding interval is stable, that is, the interval is equal to the lap length set by the touch screen;

2. The paper break is stable, and there is no or seldom the phenomenon of continuous paper.

3. The speed ratio of each shaft can be adjusted to reduce the trouble of mechanical adjustment.

3. INVT Solutions

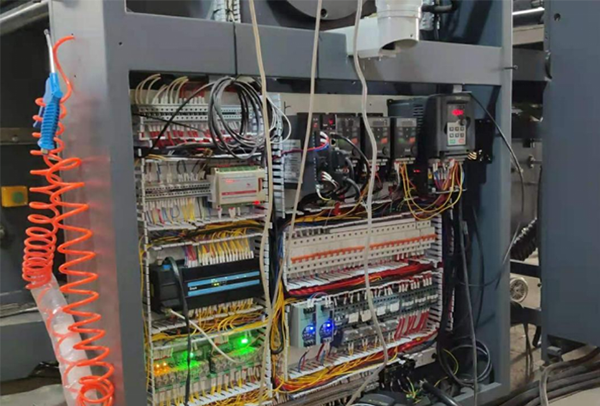

According to customer needs, INVT launched a new system solution configured as GD20 inverter, DA200 servo driver and two IVC3 series PLCs.

Among them, the IVC3 bus type PLC supports 8 channels of 200KHZ pulse output, which can realize high-speed pulse control of the servo driver. Cooperating with the speed feedforward function adjustment of INVT DA200 servo driver, it can solve the problem of paper gap deviation.

3.1 Electrical selection

| Name | Model | Quantity | Control instruction |

| Control instructions | VS10 inch touch screen | 1 | The window of human-computer interaction, data interaction through Ethernet communication |

| Programmable Controller | IVC3 series PLC | 2 | The core of data control processing and information transmission, mainly for control logic and data calculation |

| Paper feeding servo | DA200 servo | 1 | Following the movement of the conveying host, the PLC calculates the electronic gear ratio according to the length of the paper, and writes it into the relevant parameters of the servo drive through 485 communication |

| Paper feeding servo | DA200 servo | 1 | Following the movement of the conveying host, the PLC calculates the electronic gear ratio according to the length of the paper, and writes it into the relevant parameters of the servo drive through 485 communication |

| Paper feed motor | Servo motor | 1 | |

| Conveyor/main paper lift/secondary paper lift/glue/disc knife/receiving paper/tearing paper/receiving paper lifting inverter | GD20 inverter | 8 | Follow the movement of the conveying host, calculate the frequency of each axis according to different speed ratios (the speed ratio can be adjusted freely on the touch screen), and send them to the inverter through high-speed pulses |

3.2 Detailed plan

1. The system adopts INVT IVC series programmable controller. Due to the long distance between the paper feeding and paper cutting equipment, in order to prevent the long-distance transmission signal from being disturbed, each of the two parts is equipped with a separate controller. Can communication is used to exchange data between the two PLCs to realize high-speed and high-response synchronization of the two parts of the equipment.

2. The system adopts the pulse type servo driver DA200, adopts the position control mode, and the pulse comes from the host encoder to realize the synchronous relationship between the host and the paper feeding servo. When the length of the material changes, the corresponding electronic gear ratio is calculated according to the material length and lap length input by the touch screen, and the speed of the paper feeding line is changed by writing to the servo driver through Modbus communication, thereby ensuring the accuracy of the lap position.

3. The system adopts GD20 frequency converter and vector control platform product, which has powerful functions and excellent performance. It is suitable for small and medium power applications and is widely used in food, printing, packaging and other industries. Here, the inverters all use HDI given frequency, HDI has the advantage of high speed and no delay compared with Modbus communication given frequency.

4. In terms of touch screen interaction, the speed ratio of the main machine corresponding to paper delivery and tearing can be changed on the touch screen. Compared with the previous adjustment of the appropriate speed ratio through the chain reducer, it is more easy to use and flexible, and solves the problems caused by the speed ratio. Unsuccessful paper break phenomenon.

4. Advantages of the program

1. High precision of paper feeding gap: the speed of the main machine is set to 65 m/min, and the parameter of servo retention pulse is monitored, which is basically controlled at about 3-5. Except for paper slipping, theoretically there will be no deviation of half a centimeter before. The paper feeding servo and the main machine have good followability, which ensures the accuracy of the joint.

2. More stable paper breaking: The speed ratio of paper receiving and tearing is opened on the touch screen, which can be fine-tuned according to the actual situation. The design principle of paper breaking is: when there is material, it will trigger the incoming paper photoelectricity, and use the encoder to count and determine the incoming material position. Generally, the paper breaking cylinder will be triggered at half of the paper length to complete the paper breaking action. This solution can effectively reduce or eliminate the unsuccessful situation of paper breaking.

5. Conclusion

In the laminating machine solution launched by INVT, the main machine is driven by a 5.5KW frequency converter, and the feeder is driven by a 1.5kw servo drive. The electrical structure is simple, and the servo drive feeder can ensure the position accuracy of the paper sheets. Through INVT's solution, the pre-coating laminating machine has achieved high paper feeding position accuracy and low paper lamination deviation, which can effectively ensure the stability of the paper breaking position and the lamination effect of the film and paper.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.