1. Excellent control performance

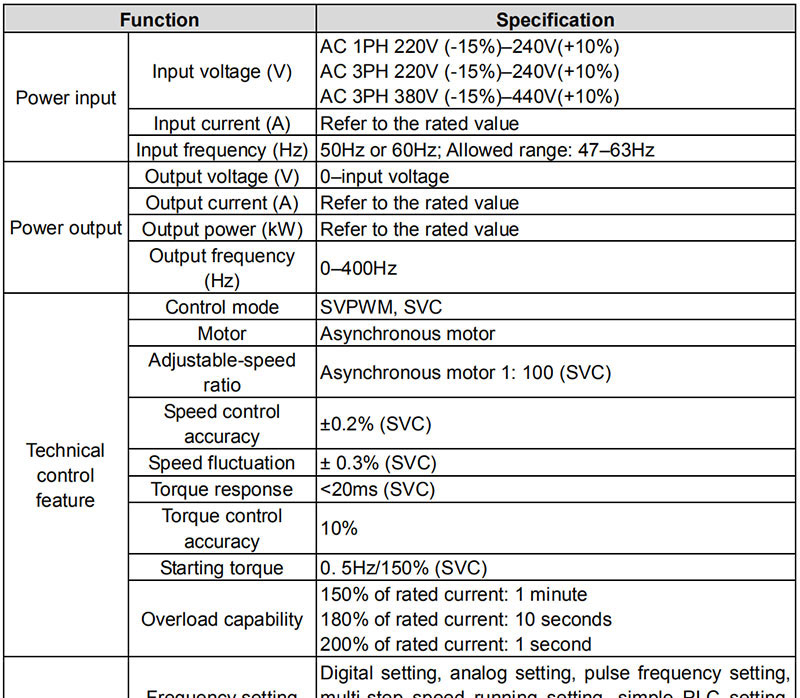

- Adopts sensorless vector control for superior performance.

- Features both static and rotating motor parameter auto-tuning.

2. Optimized structural design

- Compact dimensions save valuable installation space.

3. Rich configuration and interfaces, powerful functionality

- Standard built-in RS485 communication port with multiple I/O terminals and detachable keypad interface for flexible field applications.

- Built-in DC reactor (standard for 18.5–110kW models) improves power factor.

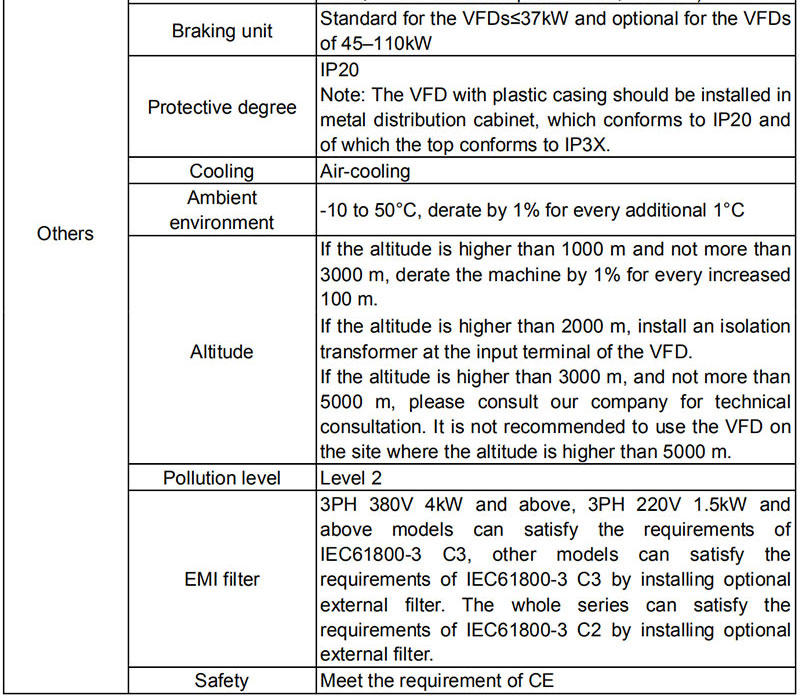

- Integrated braking unit (standard for ≤37kW models; optional for 45–110kW models).

4. Multiple installation methods

- 380V 2.2kW and lower models support both DIN rail mounting and wall mounting; 380V 4kW and above models support wall mounting and flange mounting.

5. Ease of use and maintenance

- Independently removable cooling fan facilitates maintenance.

- Standard configuration includes an external LED keypad; supports optional LED keypad with parameter copy function available for diverse application needs.

6. Integrated functions for versatile applications

- Includes basic PLC, multi-speed control, built-in PID, torque control, multi-point V/F curves, multiple braking methods, ride-through for power loss, and more.

Treadmill Case in India - INVT GD20 Series VFDs

2020-04-03INVT PLC HMI Servo System Applied for Auger Filler in India

2020-12-23INVT Control System Solution for High Speed Bag Making Machine

2021-06-10INVT Solution for End Cover Dispensing Machine System

2024-02-28INVT TS635 PLC for Gluing Machines in China

2024-06-12

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.