If network online, means the GPRS adaptor APN information is correct. RS485 off-line means the tac file is incorrect, please contact INVT to update tac configuration file.

If the network and 485 status of GPRS module are displayed on the website, it means it can be used normally.

If only the network is online, check whether there is a problem with the 485 wiring and try to replace the shielded wire. If not, you can contact INVT to upgrade the internal TAC files remotely.

If the network and 485 status are offline, but the device has been connected and powered on, it means that the internal APN information and TAC file need to be updated. Please contact INVT to update.

INVT 2G IOT module needs to write the APN information of SIM card ,local operator, otherwise it can't connect to 2G network.

If you need to update the APN information, you need to prepare a USB to 422 cable, and contact NVIDIA technical support to obtain the upgrade software and tutorial.

Operation steps, please refer to below video link:

SOLARMAN weisite

Solarman business(pro): https://pro.solarmanpv.com

Solarman(home): https://home.solarmanpv.com

The business version can manage its own sub customer members and power stations.

The home version is only suitable for end customers to manage their own power stations. After login, you can click help to download the platform manual for learning.After create a plant,can follow to add your data logger into your solar plant.

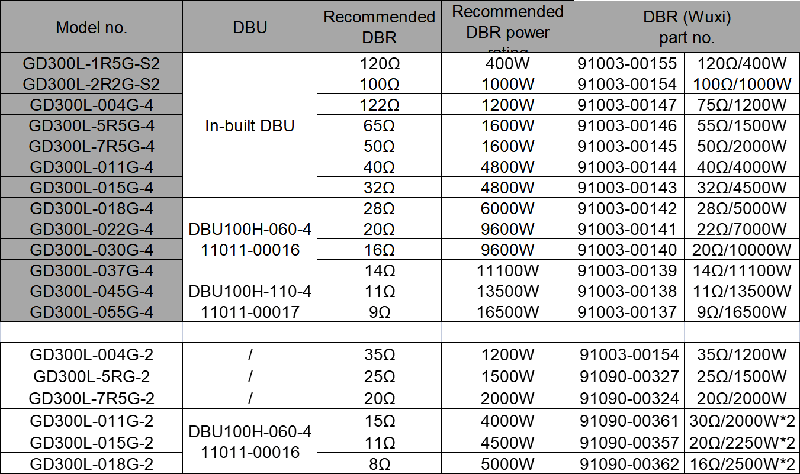

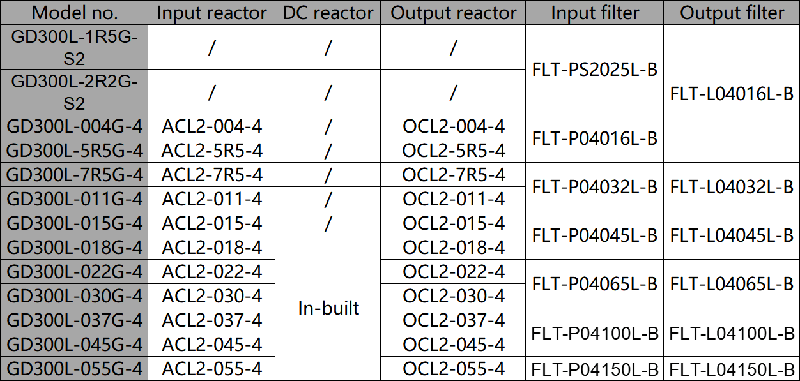

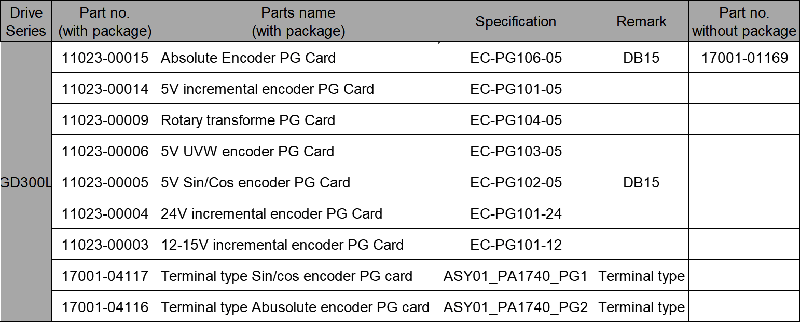

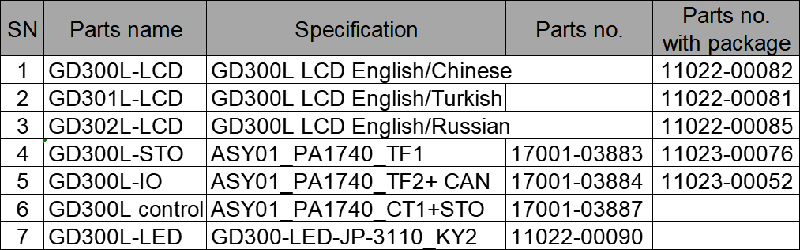

The optional parts for GD300L are DBU&DBR, Reactor, Filter, many kinds of PG card, LCD/LED keypad, IO card, STO card etc. Please refer to the attached optional parts list.![]()

In order to select proper GD300L, need to collect the below information: motor parameters, encoder parametes, signals required between controller and GD300L, environment conditions, please refer to the attached table.

In order to select proper GD300L, need to collect the below information: motor parameters, encoder parametes, signals required between controller and GD300L, environment conditions, please refer to the attached table.

![[1].png](/ueditor/php/upload/image/20220831/1661907410614154.png)

Photovoltaic panels also have efficiency degradation during actual use, such as shelter from leaves and dust on the surface of the photovoltaic panel, temperature, and mounting angle of the bracket. Regular cleaning of impurities on the surface of photovoltaic panels can increase the power generation rate.

How to solve the automatic trip of the AC circuit breaker:

The output circuit breaker tripping generally indicates that there is a short circuit in the circuit. Such a situation occurs frequently. It may be that the internal drive board of the inverter has a short circuit, and the drive board and IGBT need to be replaced.

Yes, non-standard software needs to be customized. Note that the three-phase 220VAC current is nearly twice as large as the 380VAC current, so it needs to be used at reduced power.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.