Abstract: The process of plastic straw making machine involves converting raw plastic materials into finished products in the form of straws. The machine works by melting the plastic and then forcing it through a mold to form a tube, which is then cooled and shaped to desired lengths.

Keywords: IVC1L PLC , DA200 Servo set , GD10 VFD and VS series HMI.

1. Introduction

MACHINE PROCEDURE:-

In this machine there are four process unit involved –

1. Extruder unit – It is basically a unit which used to convert Raw material into liquid form of plastic. It runs from VFD and heaters. After converting plastic form into liquid next unit working starts.

2. Cooling panel & Die unit – In this unit basic work is to cool down plastic temperature & with the help of die give form of straw.

3. Puller – Pulling speed need to sync with cutter and extruder unit because according to pulling length width of plastic straw depends & also the quality of straw.in this unit we used Gd10 VFD to run rollers.

4. Cutter – Here we used DA200 servo drive set its speed sync with roller speed and it is used to cut fix length without any variation of different straw. There are two length required as per customer need so we have given this option in HMI.

Whole machine is in sync with all units & and for monitoring & data filling we used HMI in machine for customer ease.

2. Project information and Solution

* Project information

Site information: Plastic straw pipe making machine manufacturing company.

* Market Demand:

In 2023, the global plastic straw market size was valued at approximately USD 4.5 billion, with projections suggesting it could reach USD 6.3 billion by 2032, growing at a compound annual growth rate (CAGR) of 3.8% during the forecast period. This growth is attributed to the continued demand in the food service industry alongside a variety of convenience-driven consumer behaviors which advocate for single-use products. Despite environmental concerns associated with plastic straws, their lightweight, cost-effective production and versatility still make them a preferred choice across the globe, albeit amidst increasing regulatory pressures.

* Customer Demand:

Main concern of customer is of accuracy, cost effective & ease to operate solution.

INVT have given solution with accuracy ease to operate & cost effective with INVT PLC HMI VFD & SERVO DRIVE.

We have given VFD & PLC on Modbus communication for feeding speed reference easy from HMI.

DA200 servo drive is used and customer is satisfy with accuracy on open loop.

* INVT solution

Product | Model no. | Qty | Application |

PLC | IVC1L0806MAT | 1 | CONTROLLER |

HMI | VS-07QE | 1 | HMI |

SERVO SET | SV-DA200-1R0-4-E0 SV-MM13-1R0E-4 | 1 | CUTTER |

VFD | GD10-1R5G-4-B | 1 | FEEDER MOTOR |

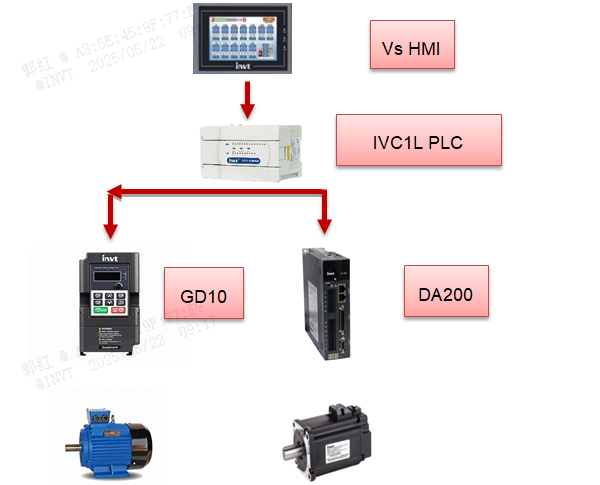

* System Configuration:

* System commissioning

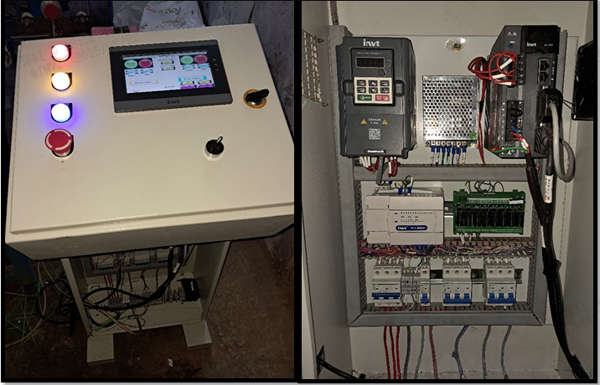

Control panels

3. Advantages and benefits

• High production as machine running in automatic process.

• All data possible to feed & monitored through HMI screen.

• Fault finding is easy.

• As we give length option in HMI customer only need to feed length and machine runs according with calculation done in PLC so it is operator friendly.

• Accuracy of machine is high.

4. Conclusion

IVC1L, Da200 servo drive, VFD and VS series HMI are all used to operate & collect all data of machine to meet the process requirement. INVT has given Cost effective solution in Plastic straw pipe making application in India and machine is successfully running with customer satisfaction.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.