1. Introduction

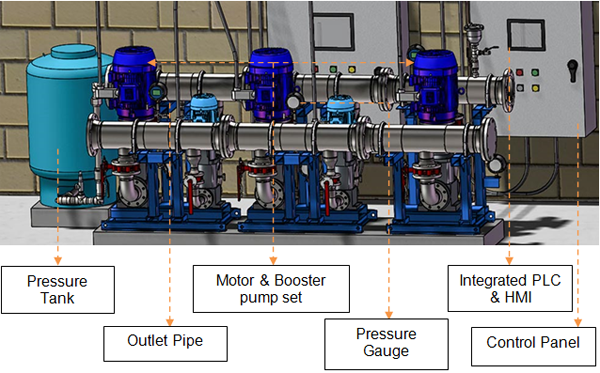

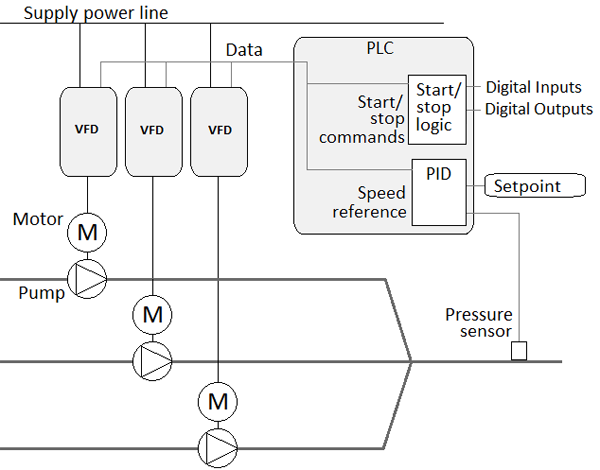

Booster pump is a pump used for pressurization. Its main applications include water heater, high-rise building with low water pressure, sauna, bath and other pressurization, solar automatic pressurization, reverse osmosis water purifier pressurization and so on. Booster pump provides a variety of optional features like: thermal overload protection, rated run continuously and multi information display, etc. Sensors, HMI and PLC with digital input / output, analog input and outputs are installed to achieve these functions. The system diagrams are as below:

Booster pump system components

Booster pump system control diagram

Site device photo

2. Project information and Solution

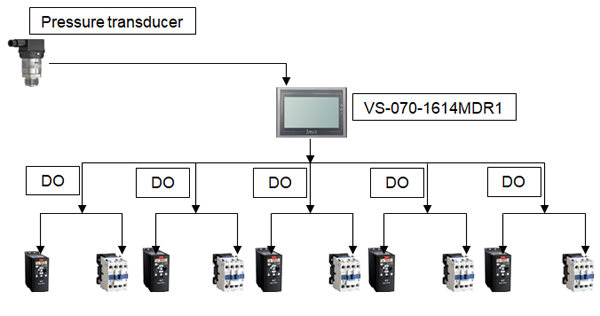

There is a commercial building need booster pump to increase the water pressure and flow. Total five pumps are there, need to control by PID to maintain the pressure. In order to saving cost and save the installation space, INVT control solution is as below:

Product | Model no. | Qty | Application |

Integrated PLC/HMI | VS-0701614MDR1 | 1 | Controller |

System configuration

The control diagram is as below:

3. System commissioning

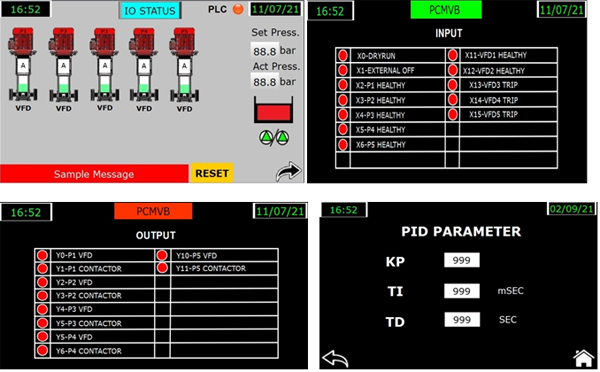

According to the control logic and display requirement, PLC and HMI program are made and uploaded to VS-070-1614MDR.

The HMI pages and control panel photos are as below:

HMI pages

Control panel photos

4. Advantages and benefits

After commissioning, the system runs steady; the water pressure is maintained well with high accuracy. The advantages and benefits are as below.

* Combo HMI and PLC, cost effective.

* Compact size, saving installation space

* PID control maintains the pressure steady.

* Friendly user interface, easy to operate

* Cascade of pumps, high Efficiency.

5. Conclusion

Normally for this system needs HMI and PLC separately, but INVT provides an integrated PLC/HMI which have 2 analog input, one analog output, Modbus port inbuilt to fulfill this requirement of booster pump application which is very economical, compact and the pressure control resolution up to 0.1 bar. Customer is very satisfied with this solution.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.