Background

The rolling mill is a kind of equipment for compressing and deforming metal materials, and cold-rolled silver is one of the metal materials produced and processed by the rolling mill. During the steel rolling process, cold-rolled silver needs to be cooled to ensure product quality and production efficiency. The cooling water pump is a device that provides cooling water flow, and its performance has an important impact on the production efficiency and product quality of the rolling mill.

Project Difficulties

The development of intelligent control technology for circulating cooling water system has become an important part in the construction of steel mills. The customer considers that the site needs to change roll every 4 hours, and two water pumps need to be switched when changing the roll, and at the same time, the impact on the power grid should be reduced, and there should not cause impact on the the power grid when switching.

INVT’s solution

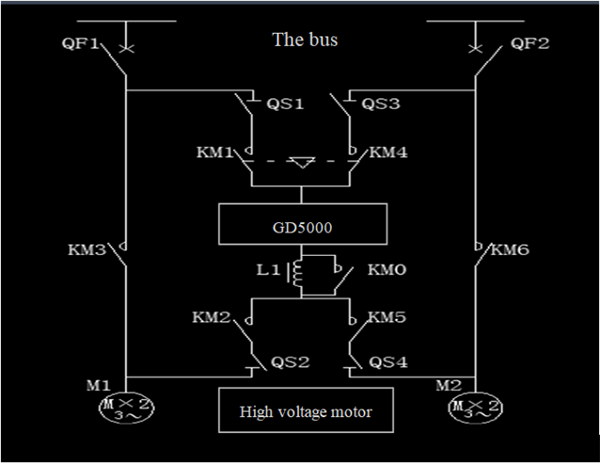

Considering the on-site control process, INVT decided to use GD5000 series high-voltage inverters to realize automatic commutation. The site is equipped with a non-disturbance switch cabinet and a one-to-two automatic bypass cabinet. The one-to-two non-disturbance switch ensures the safety of the power grid during the commutation process with minimize shocks and avoids excessive loads on equipment.

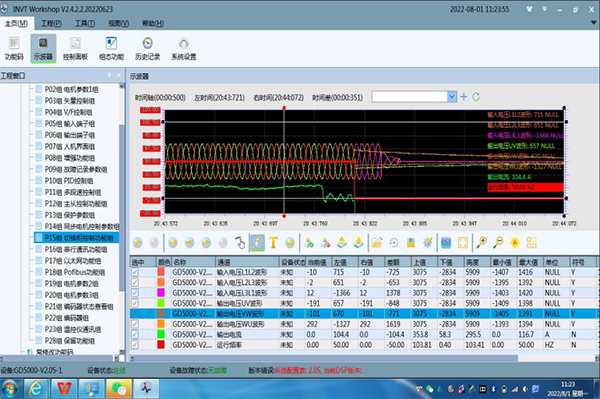

GD5000 series high-voltage inverter has multiple protection mechanisms and intelligent adjustment functions, which can flexibly adjust the frequency and voltage of the water pump according to the different production needs of the rolling mill to ensure optimal performance and energy efficiency. GD5000 is also equipped with a complete monitoring and alarm system to monitor the status of the water pump in real time to ensure the continuous, stable and reliable operation of the equipment.

Advantage

1. One-to-many solutions to reduce equipment investment costs.

2. Realize the sequential soft start of multiple devices, reducing the impact on the power grid and machinery.

3. Undisturbed switching between the power-frequency and variable frequency, easiable and safe operation.

Conculsion

INVT GD5000 series high-voltage inverters have multiple advantages in the application of cooling water pumps in rolling mills, providing customers with efficient and stable cooling water pump control, and helping customers improve the economic benefits and production efficiency.

In addition, INVT has made outstanding achievements in different large-scale equipment and production processes in industrial production and manufacturing fields such as electric power, mining, water supply, sewage treatment, metallurgy, and petrochemicals, and has won the trust and recognition of many enterprises.

Site figure

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.