Abstract: This article discusses the application of INVT GD5000 series medium-voltage variable frequency drives (VFDs) on the main exhaust fan of the blast furnace in the pelletizing project of an Algerian steel plant. Practical operation has demonstrated the feasibility, necessity, and energy-saving advantages of applying medium-voltage variable frequency speed control to large fan loads, promoting its wider adoption in blast furnace systems within steel plants.

Keywords: steel plant, blast furnace main exhaust fan, medium-voltage variable frequency drive, air-water cooling

1. Introduction

The main exhaust fan is one of the most critical pieces of equipment in a steel plant. It utilizes negative pressure to draw combustion flames into the blast furnace, ensuring complete combustion and stable pellet quality. Operating parameters such as airflow and pressure directly influence production quality and efficiency.

The fan motor is also a major energy consumer, accounting for nearly two-thirds of the total energy consumption of the sintering production line. Traditional control methods rely on synchronous motors combined with liquid resistance cabinets for starting, while airflow regulation is achieved through damper adjustment. This approach results in low efficiency, limited real-time control capability, and restricted starting frequency.

With the rapid development of medium-voltage and medium-power variable frequency drive technology, soft start and precise speed regulation have become more mature and reliable. In the Algerian steel plant pelletizing project, a medium-voltage VFD is adopted to regulate fan motor speed, significantly improving operational efficiency and achieving energy-saving control.

2. Introduction to the Blast Furnace Ironmaking Process

Blast furnace ironmaking is a continuous process that reduces iron ore into molten iron. Raw materials such as iron ore, coke, and flux are charged from the top of the furnace in specified proportions, forming alternating layers inside the furnace. As materials descend, they undergo reduction and melting, eventually forming molten iron and slag in the furnace hearth.

Preheated air is blown into the furnace through tuyeres located around the lower perimeter. Carbon in the coke reacts with oxygen to produce reducing gases such as carbon monoxide and hydrogen, which remove oxygen from the iron ore. Molten iron and slag are periodically discharged, while blast furnace gas exits from the top, is cleaned, and reused as fuel for other equipment.

3. Introduction to the Blast Furnace Main Blower Fan

The blast furnace main blower fan is a vital piece of equipment in ironmaking plants, responsible for supplying stable airflow required for smelting. Stable and reliable fan operation directly affects top pressure regulation, furnace utilization coefficient, and iron output.

Unexpected fan shutdowns caused by electrical, mechanical, or control failures may result in serious operational accidents such as airlock slagging or gas backflow, posing severe safety risks and economic losses. Therefore, the air supply system must provide stable regulation capability and a reliable safety control system to support continuous production.

4. On-Site Equipment Conditions

| Fan Type | Centrifugal Fan |

| Motor Model | YX2-BPKK560-6 |

| Rated Power | 5200 kW |

| Rated Current | 545 A |

| Rated Voltage | 6.6 kV |

| Rated Power Factor | 0.886 |

5. Control Scheme

5.1 System Main Circuit Control Scheme

The main blower fan supplies hot air to the blast furnace hearth while supporting coal powder injection, forming a core component of the blast furnace system. As smelting intensity increases, higher hot air volume and stable airflow regulation become essential for improving iron output and maintaining uniform furnace conditions.

This project adopts the INVT GD5000-A7100-6.6-D medium-voltage variable frequency drive for soft start and variable speed control of the blast furnace main blower fan in the Algerian pelletizing project.

5.2 Control Performance Features

Frequency setting methods include digital setting, analog setting, high-speed pulse input, multi-speed terminal setting, Modbus communication, and Profinet communication. Operating modes support HMI control, terminal control, Modbus remote control, and Profinet communication control.

The system provides start-up pre-torque compensation, DC braking during start-up and shutdown, and automatic voltage adjustment to maintain stable output voltage during grid fluctuations.

5.3 Advantages of Using a Variable Frequency Drive

With the VFD, fan startup time is reduced from approximately two minutes to only a few seconds, while startup current is limited to 1.2–1.5 times the rated current.

Soft start and soft braking eliminate current surges and mechanical shocks associated with damper-based control, significantly reducing stress on motors, bearings, and fan blades.

The medium-voltage VFD supports both local touchscreen control and remote DCS control, allowing operators to adjust motor speed and airflow precisely from the control room, improving operational flexibility and safety.

6. Conclusion

Based on on-site operation, the INVT GD5000 medium-voltage VFD demonstrates a compact footprint, easy installation, and simplified commissioning. Users can complete setup by selecting motor voltage, configuring parameters, and performing rapid self-learning.

The system achieves open-loop vector control with 150% rated torque output at 0.5 Hz and a torque response time of 100 ms, fully meeting application requirements. Real-time monitoring of power unit status enables early fault prediction and enhances system reliability. The successful application further highlights the advantages of meidum-voltage VFDs in fan and pump energy-saving applications.

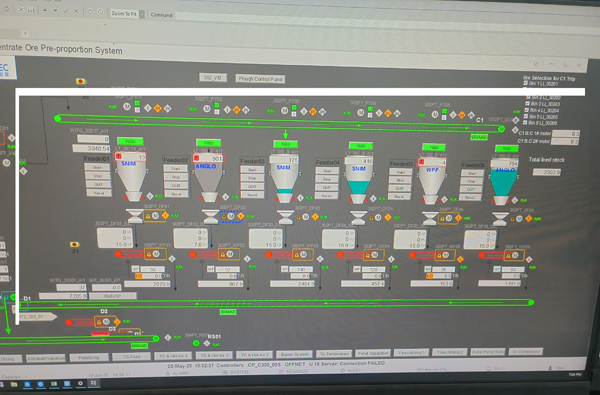

7. On-Site Photos

On-site installation and operation photos of the GD5000 medium-voltage VFD system applied to the blast furnace main exhaust fan.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.