Abstract: A real estate developer specializing in mid-rise residential and commercial buildings faced challenges with ride comfort, energy efficiency, and compatibility when integrating Montanari PM machines and Heidenhain encoders into their elevator systems. INVT provided the GD390L inverter solution, delivering smooth, reliable, and energy-efficient elevator operation, while significantly reducing commissioning time and improving system stability.

Keywords: INVT GD390L, PG card, Montanari PM Machine, ERN 1387 Encoder.

Customer Background

The customer is a developer of mid-rise residential and commercial buildings in India, seeking an elevator control system that delivers reliability, enhanced ride comfort, and improved energy efficiency. Their installations typically include 5-floor elevators with a rated speed of 1.0 m/s and a load capacity of 6 persons (408 kg).

Challenges

• Require smooth acceleration and deceleration to enhance passenger comfort.

• Must minimize noise and vibrations, especially during start/stop.

• Integration with Montanari PM machines and Heidenhain SinCos encoders required compatibility and precision.

• Operating in higher ambient temperatures necessitated a robust inverter solution.

• Emergency-rescue capability and light-load direction detection were essential for safety and functionality.

• Demand for flexible control modes and encoder options.

INVT Solution

INVT provided the GD390L inverter solution integrated with the Montanari PM machine and Heidenhain SinCos encoder. The GD390L elevator drive offered:

• Closed-loop vector control with encoder feedback for smooth motion.

• Advanced S-curve acceleration/deceleration algorithms, improving comfort during starts and stops.

• Multiple encoder compatibility, including SIN/COS, ENDAT, SSI, and incremental encoders.

• Load compensation and rollback protection, increasing ride consistency and safety.

• Built-in features like removable terminal board, LCD/LED keypad, and OTA/IoT readiness for smart upgrades.

• Flexible tuning for both static and rotational conditions, enhancing setup speed and accuracy.

* Configuration of GD390L Elevator

Tab 1 Lift information:

Lift speed | 1.0 m/s |

Capacity | 6 persons, 408KG |

Floor | 5 floors |

Power supply | 3phase 380V |

Motor type | Synchronous motor |

Rated power of motor | 2.8kW |

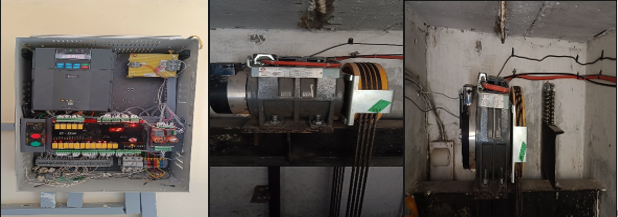

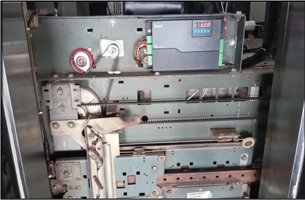

Fig: - INVT GD390LControl Panel and motor with nameplate

* GD390L electrical configuration

According to the lift configuration and the demanding functions, we provide the electrical solution as follow. Considering higher ambient temperature, one grade higher of machine rating is selected.

Tab 2 Configuration list

Item | Model | Qty |

GD390L Inverter | GD390L-004G-4-E-Y | 1 |

EC-PG102-05-T | PG CARD | 1 |

Gearless Motor | Montanari Machine | 1 |

Encoder | HEIDENHAIN SinCos 1387 | 1 |

Brake resistor | 120Ohm/1200W | 1 |

* Result

• Achieved smooth and silent elevator operation with minimal tuning.

• Ride comfort improved due to S-curve acceleration/deceleration and advanced control algorithms.

• System showed robust operation under variable load and temperature.

• All safety mechanisms including brake control, overload protection, and STO performed reliably.

• Energy efficiency improved, reducing long-term operational cost.

Customer Benefits

The customer reported high satisfaction with the performance and flexibility of the GD390L drive. Key points of appreciation:

• Quick installation and commissioning, thanks to intuitive parameter setup and auto-tuning.

• Significantly reduced jerk and noise, enhancing user experience.

• Reliability during emergency and light-load conditions exceeded expectations.

• Strong support for encoder compatibility and versatile control modes.

Conclusion

The successful deployment of the INVT GD390L inverter with the Montanari PM machine and Heidenhain encoder delivered a modern, efficient, and highly stable elevator drive system. This project showcases INVT’s ability to meet and exceed contemporary demands in vertical transportation: smoother rides, lower energy use, faster commissioning, and full safety compliance. As the elevator industry moves toward smarter, quieter, and more efficient systems, INVT is positioned as a key technology partner in modernizing and future-proofing lift control systems.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.