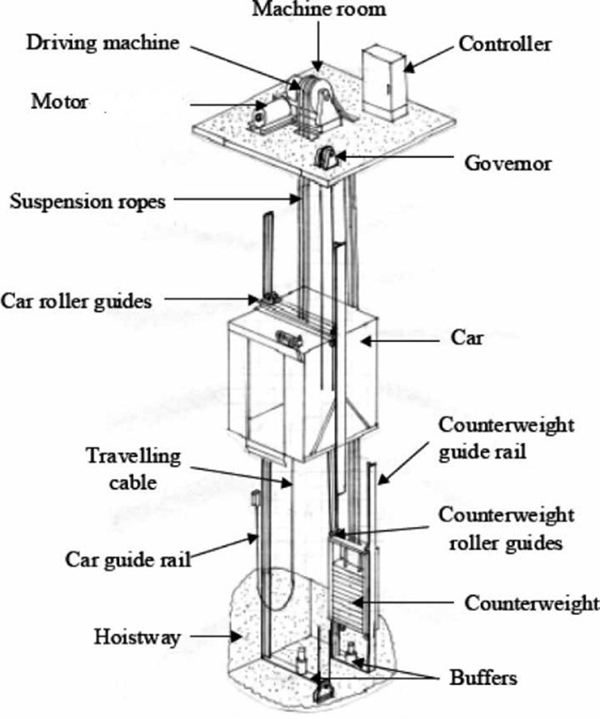

Introduction for Elevator

Traction elevators are driven by alternating (AC) or direct current (DC) electric motors. The friction between the hoist steel ropes and the sheave is used in traction elevators to move the car. Traction elevators use a counterweight to offset the occupants and elevator cab's weights so that the electric motor doesn’t have to move as much, making traction elevators much more energy and power efficient than hydraulic elevators. Traction elevators have remained relevant in the building industry. The uniqueness of traction elevators makes them stand out, especially for mid to high-rise buildings, making them the commonest choice.

Components of Traction Elevator with Machine Room

Customer Requirement

The site was a commercial building. Customer required a compact, good-looking panel with very low mechanical sound.

Easy installation with minimal complications and fewer wires.

The panel should provide a smooth riding experience with no noise at starting and stopping.

Controller must have all safety features based on EN81 safety standards.

* Challenges

Limited installation space provided by the customer.

Low magnetic contactor on/off sound.

Gearless machine requires very high starting torque.

Need zero speed load companion feature to overcome starting jerk.

Drive should support high ambient temperature while maintaining stable performance.

INVT Solution

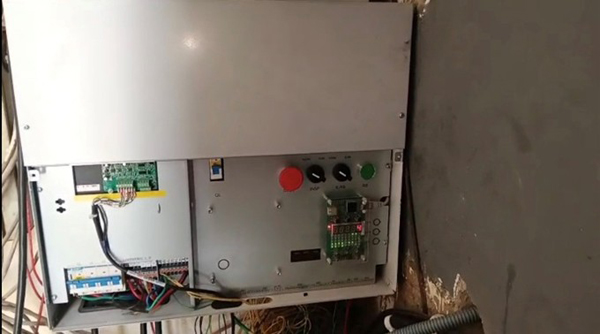

INVT provided the EC600 Intelligent Integrated Panel Solution, a next-generation dedicated elevator solution for home and commercial buildings.

* Key feature:

Noise limited to 50dB for low electrical sound.

Standard STO (SIL3), electronic star shorting for PM motor.

Standard C3 filtering, optional built-in C2 filter.

Electronic star sealing.

OTA technology.

Support for closed-loop control mode, geared & PM motors, static & rotational motor tuning.

Built-in incremental PG card for 5V, 12V, and 24V selectable; optional encoder types: SIN/COS, ENDAT, SSI.

Direct landing; advanced S-curve algorithm improves comfort during acceleration, deceleration, and stop.

Starting torque compensation to prevent rollback at startup; 200% for 10s overload capacity.

* Configuration of EC600 Elevator

- Installation of EC600 on lift has below detail:

| Parameter | Value |

| Lift speed | 0.700 m/s |

| Capacity | 408 kg |

| Floors | 5 floors |

| Power supply | 3-phase 380V |

| Motor type | Synchronous |

| Rated power | 3 kW |

Tab 1 Lift information

Fig: EC600 Control Panel

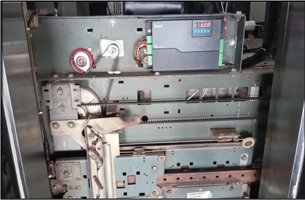

Fig: Motor with nameplate

* EC600 Electrical Configuration

Based on lift configuration and required functions, the electrical solution is as follows. Considering higher ambient temperature, one grade higher of machine rating was selected.

| Item | Model | Qty |

| EC600 Inverter | EC600-MR2-7R5-4-B-SU | 1 |

| Gearless Motor | SHARP | 1 |

| Encoder | HEIDENHAIN SinCos | 1 |

| Brake Resistor | 122Ω / 1200W | 1 |

Configuration List

Customer Benefits

Smooth and silent elevator operation during running.

Quick installation and commissioning, saving time.

Energy-efficient compared to geared machines.

Electronic star sealing adds extra safety.

Conclusion

The successful installation of the INVT closed-loop system with a 1387 SIN/COS encoder provided a jerk-free, smooth-running experience with high system stability. This project demonstrates INVT’s high-efficiency, advanced technology system capable of handling all types of challenges with energy-efficient, low-cost, and time-saving solutions.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.