Background Introduction

With the rapid advancement of elevator technology and the increasing maintenance costs of aging branded elevator systems, the Peruvian market has experienced a growing demand for modern elevator solutions. The INVT GD300L elevator drive, a mature and highly competitive elevator-specific drive, utilizes the latest control technologies to significantly improve safety, reliability, performance, and functionality. The GD300L has proven to be an ideal solution for elevator retrofitting projects, offering both open-loop and closed-loop vector control capabilities for asynchronous and permanent magnet synchronous motors.

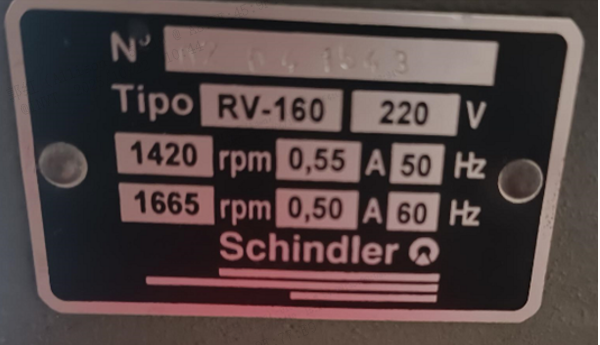

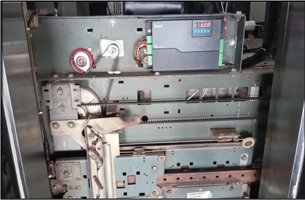

In this case, the GD300L was chosen for the modernization of a Schindler elevator system located in the center of Lima, Peru. The original elevator had been using Schindler’s open-loop control solution, but after years of operation, the system’s performance had declined, and maintenance costs became prohibitively high. The INVT GD300L was selected as the optimal solution for upgrading the elevator, addressing these issues while enhancing overall system performance.

Customer Needs

The key requirements for this elevator modernization project were:

1. Operational Stability: The new system needed to offer reliable and stable performance, ensuring the elevator operated smoothly without interruptions.

2. Enhanced Ride Comfort: The upgrade aimed to improve passenger comfort by reducing noise and providing a smoother ride.

3. Cost-Effective Solution: The property owner needed a solution that would reduce long-term maintenance costs while improving elevator performance.

INVT Solution

The INVT GD300L was installed to replace the original Schindler system. Key features of the solution included:

• Open-Loop Vector Control: The GD300L supports open-loop vector control, enhancing the system's ability to regulate motor speed and torque for smooth operation.

• Advanced Torque Compensation: This feature prevents rollback during operation, ensuring smooth starts and stops, enhancing ride comfort.

• Forced Deceleration: To prevent overtravel at the top and bottom of the elevator shaft, forced deceleration was integrated into the control system.

• Emergency Rescue Operation: The system supports emergency operation with AC220V UPS, ensuring the elevator can continue to operate during power outages.

• Compatibility with Multiple Encoder Types: The GD300L is compatible with a wide range of encoder types, ensuring flexibility and ease of integration with different elevator systems.

The electrical configuration for the retrofit included:

• Drive: GD300L-015G-2 (1 unit)

• Braking Unit: DBU100H-060-2 (1 unit)

• Geared Motor: Schindler, 15kW, AC220V (1 unit)

• Brake Resistor: 10Ω / 4500W (1 unit)

Solution Value

The installation of the INVT GD300L resulted in several key improvements:

• Operational Stability: The GD300L provided a stable and reliable system, reducing downtime and improving the elevator’s performance.

• Ride Comfort: The advanced torque compensation algorithm and smooth speed regulation significantly improved the passenger experience, providing a quieter and smoother ride.

• Noise Reduction: The system’s ability to minimize motor noise contributed to a more pleasant environment for building occupants.

• Reduced Maintenance Costs: With the upgrade to the GD300L, the building owner experienced lower maintenance costs, as the new system was more reliable and required less frequent servicing.

The successful application of the GD300L in this elevator retrofit project has demonstrated its effectiveness in improving both performance and cost-efficiency. Similar modernization projects are currently underway in Peru, with the GD300L's advantages being continually validated in the elevator industry.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.