Abstract: A winder and unwinder machine are essential in various industries, particularly in the manufacturing and processing of web materials such as paper, film, textiles, rubber, wire, and tape. This article introduces the application of INVT HMI and VFDs with torque control function in such machines.

Keywords: GD200A Drive, QE series HMI, Winder Unwinder, Torque control

I. Introduction

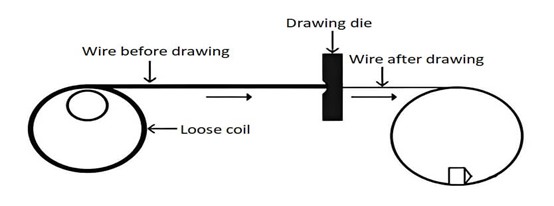

MACHINE PROCEDURE:

The process of winding, unwinding, slitting, and rewinding may seem simple but requires precision to ensure high-quality output, especially at high production speeds. Here's a breakdown of the machine types:

Winders: Create a Master Roll (or Jumbo Roll) from the continuous wire off the production line.

Unwinders: Unwind the Master Roll to produce smaller finished reels. Wire unwinding may require up to four unwinders.

Unwinding methods include:

Peripheral unwinding (motorized belts) for wire and nonwoven reels

Axial unwinding (motor with axial coupling) for paper reels

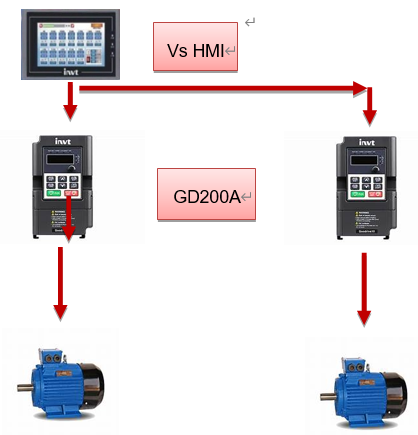

The VFD is operated through an HMI using the Modbus protocol.

HMI functions include Start, Stop, Reset, Emergency Stop, and monitoring of power, current, voltage, and frequency.

One GD200A VFD is used on the wire unwinding machine; another on the torque control winding machine.

II. Project Information and Solution

1. Project information:

Customer: Wire winding and unwinding machine manufacturing company

2. INVT Solution:

| Product | Model No. | Qty | Application |

|---|---|---|---|

| HMI | VS070QE | 1 | Controller |

| VFD | GD200A (7.5kW & 5.5kW) | 1 | Controlling Torque |

3. System Configuration:

4. System Features:

The HMI provides convenient control and commissioning, reducing operational complexity. Even ordinary personnel can operate it after minimal training.

During operation, the HMI displays parameters such as current, voltage, and fault information, allowing real-time monitoring and enhancing production safety.

The GD200A VFD applies advanced open-loop vector control, ensuring high torque at low speed.

III. System Commissioning

IV. Advantages and Benefits

High-accuracy torque control eliminates anti-winding issues

High-speed and stable operation

High performance with good thread sealing and continuous running capability

User-friendly HMI for easy setup and monitoring

Simple operation: only need to load the material and empty roll

V. Conclusion

Automatic winding machines suit a wide range of manufacturers. INVT provides an economical and fully automatic solution that reduces manpower needs and minimizes human errors. This solution is ideal for customers looking to upgrade from manual to automated operations.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.