Northeast Light Alloy Co., Ltd. was founded in 1952 and enjoys the reputation of "the silver pillar of the motherland" and "the cradle of China's aluminum and magnesium processing industry". The company is an important construction project among the 156 key projects during the "First Five-Year Plan" period of the country, and has made outstanding contributions to the national defense industry, aerospace industry and national economic construction.

As time goes by, the 2100mm four-roll imported aluminum strip hot rolling mill introduced by the company in 2010 has aged and is difficult to meet the needs of modern production. It is urgent to promote domestic substitution and upgrading.

01 Customer Requirements: One-to-multi motors, stable and responsive

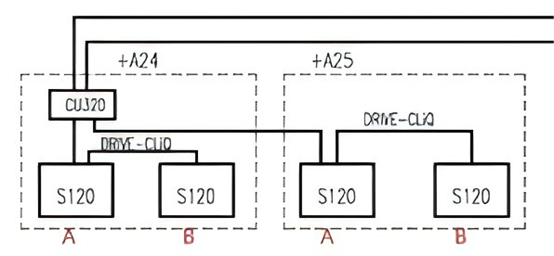

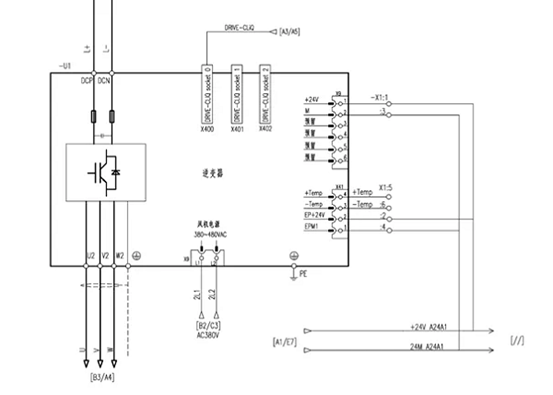

Four old VFDs (roller load 132kW) need to be replaced on site, and the load has 20 motors (5.5kW). The requirements are:

- Profibus-DP communication, the configuration can be modified, and the program is not modified due to packaging reasons

- Use the original space, the size is not larger than the original VFD

- The VFD is used to drive multiple motors, and it is required to be stable, fast in response, and the control performance is not lower than Siemens S120 series

02 INVT Solution: GD880 series VFD

In response to the specific needs of customers, INVT provides the GD880 series VFD solution. This solution not only meets the requirements of size, communication protocol, stable operation of one-to-multiple motors, and rapid response, but also wins the favor of customers with its excellent product performance, perfect on-site service and competitive price.

03 Customer Benefit: Reducing costs and increasing efficiency will determine the future of “digital intelligence”

* Cost reduction and efficiency improvement

The localized application of GD880 has greatly reduced customers' procurement costs, and brought significant economic benefits to customers while ensuring performance.

* No need to modify the program, reducing the risk of replacement

GD880 has good compatibility with imported brand VFDs. During the replacement process, customers do not need to modify the original program, ensuring the continuity and stability of production.

* High performance and stability

While meeting the roller operation requirements, GD880 achieves quick start and stop, thus improving production efficiency.

* Scalability and upgrade convenience

GD880's expandable communication card reserves an interface for subsequent equipment upgrades, which provides convenience for customers' future equipment upgrades and reduces upgrade costs.

* Timely response and quality service

INVT's technical service team provides a 24/7 response mechanism, which can respond quickly and provide professional solutions to protect customers' equipment.

The successful application of INVT GD880 series VFD on the aluminum strip hot rolling roller table not only demonstrated INVT's technical strength and service level, but also set an example for the application of domestic VFD in the field of high-end manufacturing. Through this cooperation, INVT and Northeast Light Alloy Co., Ltd. have established a closer cooperative relationship, laying a solid foundation for in-depth cooperation in the future. INVT will continue to forge ahead, promote the replication and promotion of product solutions in the metallurgical industry, build a new model for digital business development, and provide new impetus for the metallurgical and nonferrous metal industry.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.