Abstract: An automatic shrink-wrapping machine is a piece of equipment that automatically sorting the product into matrix and wraps products in shrink film, seals the edges, and then shrinks the film tightly around the product using heat, without human intervention.

Keywords: DA200 Servo, Packaging, Pharma packaging, AX PLC, Ether CAT, E-Cam, INVT, HMI, VS-Q ,Codesys

I. Introduction

MACHINE PROCEDURE:

* The machine typically has an infeed conveyor to load products, and an exit conveyor to remove the wrapped products. The conveyor is driven by VFD.

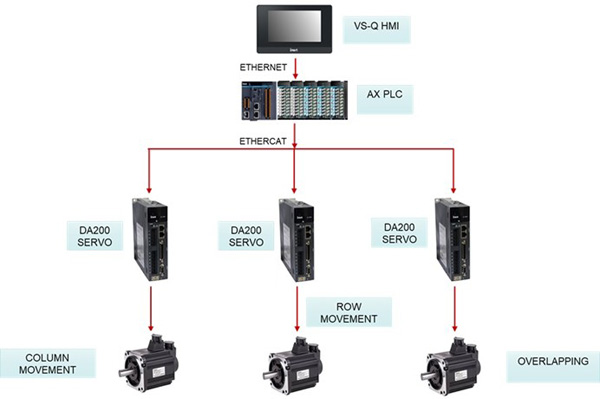

* The machine automatically sort the product as per the matrix configuration and here we have use E-cam function of AX PLC. The speed and position of product is define by external encoder which the master feedback and based on the feedback INVT’s first DA200 is synchronized to count the column and second servo is synchronized to count the rows with the help of E-cam function of AX PLC. Based on these two servo movement, product matrix will form.

* The machine automatically place the film wraps the product using overlapping function ,Here INVT DA200 servo is used to wrap the film overlapping with the help of E-cam function. Then the product matrix with overlapping shrink film, seals the edges, and then passes the wrapped product passes through a heat tunnel where the film shrinks tightly around the product. Some machines can handle various product shapes and sizes, and may include features like automatic collation and bundling.

* VS-Q HMI is used to control and monitor the entire sorting and wrapping process .In the machine, INVT has introduced the recipe functions for different product category which helps operator to select as per his requirements.

II. Project information and Solution

1. Project information

Site information: Packaging

2. INVT solution

Product | Model no. | Qty | Application |

PLC | AX72C-1608N | 1 | CONTROLLER |

EXPANSION MODULE | AX-EM-1600D | 3 | CONTROLLER |

EXPANSION MODULE | AX-EM-0016DN | 2 | CONTROLLER |

EXPANSION MODULE | AX-EM-4DA | 3 | CONTROLLER |

HMI | Vs070-QS | 1 | OPERATOR INTERFACE |

SERVO | SV-DA200-0R7-2-N0 SV-ML08-0R7G-2-1A0-1000 | 1 | Column Movement |

SERVO | SV-DA200-0R4-2-N0 SV-ML06-0R4G-2-1A0-1000 | 1 | Row Movement |

SERVO | SV-DA200-2R0-2-N0 SV-MM13-2R0E-2-1A0-1000 | 1 | Overlapping |

3. Product Feature

DA200 servo:

* Rich communication interface like EtherCAT which proivides 100 Mbps synchronization speed is used which helps to get good speed,accuracy and avoid the physical wiring.

* Load inertia identification: it has on-line and off-line two inertia identification mode, automatically identify the system internal gain parameters, and shorten the system adjusting time to get good response according to the load on motor shaft.

AX PLC:

* High-speed calculation capability uses the CPU with the basic command processing speed up to 1ns which helps to get less scan time and

* Supports EtherCAT motion communication to control DA200 servo with high precession.

* Advanced motion control functions to synchronization control and advanced motion control such as electronic cam, electronic gear, and positioning by using high-speed EtherCAT bus.

* MODBUS TCP/IP communication is inbuit in PLC which helps to communicate with INVT VS-Q series HMI.

VS-Q:

* Built-in COM port is integrated with RS232/422/485 communication modes

* Support industrial Ethernet communication, realize data exchange among multiple devices here we have used Ethernet modbus TCP/IP communication of HMI to communicate with AX PLC.

* High-capacity FLASH storage which helps to store more than 80 recipe,we have given upto 100 recipe of 10 data type for store the multiple program and use as per requirements.

3. System Configuration:

4. System commissioning

Control panels

III. Advantages and benefits

1. The shrink wrap machine uses INVT Motion based PLC AX ,In which we have developed 3 cam table ,E-Cam function is inbuilt, column(linear)movement, row(linear) movement, overlapping(rotary) movement driven by INVT servo motor and all are synchronize with respect to one external encoder.

2. INVT DA200 Supports Ether CAT communication which can reduce the wiring, trouble shooting is easier, Synchronize is faster and accurate.

3. For Different product, we have used different recipe and transfer the speed, position, ACC, DEC value through Modbus TCP/IP communication between HMI and PLC. According to these data we have calculate the cam points of each servo to synchronize and efficient results.

4. Low maintenance and high accuracy because of AC servo motor driven system.

5. As this machine is fully automatic from infeed conveyor to out conveyor so less human interference and less human errors.

6. These machines have minimal downtime and more working time, After INVT solution production rate is higher with comparison to older system. Speed of the machine depends on the product size.

7. We have developed some modification with respect to older system ,like customization as per user demand like production data logic, batch data logging, time wise product recipe selection etc.

IV. Conclusion

INVT’s solution delivered significant performance improvements in terms of speed, quality, and efficiency. Machine accuracy is better now, earlier it was trio MC403 on pulse control with servo, we have updated the system with AX PLC and DA200 servo on Ether CAT .Here we have given solution against Trio and Customer is much more satisfied with performance.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.