Abstract: This paper briefly introduces the structure and basic principle of sheet extruder machine, as well as the INVT AX70 PLC and GD350 solution for the machine control system. Engineering practice shows that INVT solution is easy to use, stable and low cost, which is worthy of market promotion.

Keywords: INVT, AX70 PLC, GD350, EtherCat

1. Introduction

Sheet extruder machine is to produce film materials with equal width, thin and uniform thickness through hot melting and pressure control according to the characteristics of plastic materials. As a means of living closely related to daily life, plastic sheet is in great demand. Plastic sheet extruder machine is the key processing equipment in the plastic machinery market. It has a good market prospect together with the back-end blister machine, cup making machine, molding machine and other units. At present, the key pressure control of sheet extruder machines on the market is generally unstable, resulting in uneven of sheet thickness and affecting the product quality of back-end equipment.

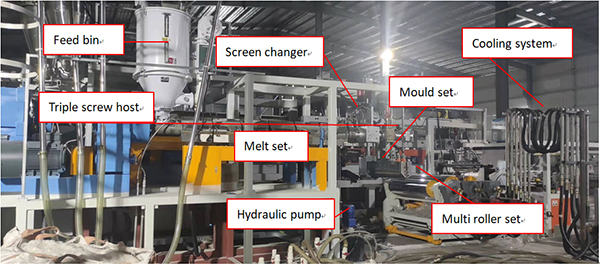

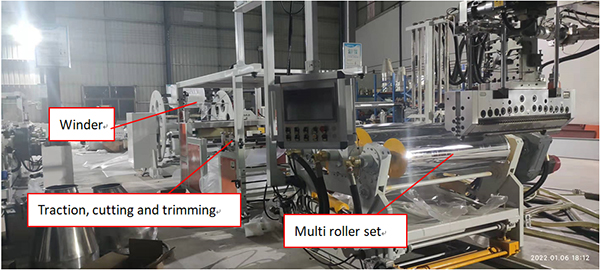

The sheet extruder machine is composed of screw host, screen changer, mold, multi roller set, conveyor, tractor, cutter and winder a coiler. The plastic particles are sent into the hot-melt cavity of the screw main machine to be hot melted into glue. At the same time, the constant pressure in the cavity is controlled to squeeze into the mold head to make flexible sheet glue with uniform thickness, and then after multi roller calendaring and cooling, the finished products are cut, closed, hauled and rolled.

2. Project demand

In a plastic sheet production enterprise in Guangdong Province, customers put forward the following requirements:

1) According to the melting point of the material, the length of the inner cavity of the host screw, the characteristics of the bent pipe, the mould set and other components, the following points must be ensured:

a. The electric heating temperature everywhere meets the standard;

b. Plastic material has good fluidity and viscosity in the cavity;

c. The communication between PLC and temperature module is normal, and it can be restored automatically after off line;

2) The feeding amount of the feeding motor must be equal to the handling amount of the screw host;

3) In order to ensure that the thickness of the sheet formed by the mould is uniform and suitable for the normal production of various raw materials (PP, PE) and shapes (prototype and sheet), it is necessary to ensure that the pressure of each screw host fluctuates stably by ± 0.2MPa, and the pressure is stable and constant again within 5-10 minutes during acceleration and deceleration;

4) The speed of three (more) roller drive and traction roller must be completely synchronized, and the speed must reach 50M / min. under high-speed operation, the traction roller must maintain constant torque control to ensure that the film is not broken and the film surface is not drawn.

3. INVT solution

1. Solution description

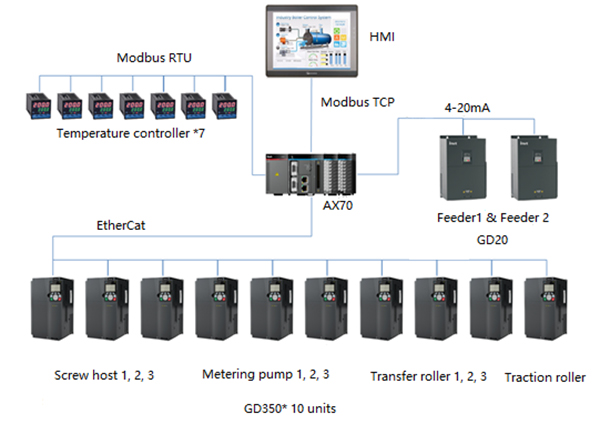

Based on the customer requirements, INVT AX70 series PLC with EtherCAT and GD350 series VFD are applied to this project. After the system development of application program, the pressure control can be stabilized within the customer requirement, and the speed synchronization rate can be more than 99.8%.

2. Solution configuration list:

Name | Model no. | Qty | Brand | Remark |

PLC | AX70 | 1 | INVT | 32DI/32DO/8AI/4AO |

HMI | 15 inch | 1 | / | |

VFD 1 | GD350 | 10 | INVT | Screw host: 3 units; Metering pump: 3 units; Transfer roller: 3 units; Traction roller: 1 unit |

VFD 2 | GD20 | 2 | INVT | Feed bin: 2 units |

3. System diagram

Control system diagram

4. Advantage and benefit

1. Easy to use: the electrical wiring system is very convenient, and the network cable can be connected;

2. Strong anti-interference: EtherCAT system has strong anti-interference, low delay, high response and high reliability;

3. Pressure stability: through pressure PID control and correction algorithm, the pressure is stably controlled within the required range within 5-10 minutes, and the unit is stable and smooth transition in the acceleration and deceleration process, which solves the problem that it is difficult to achieve pressure stability again due to the abnormal fluctuation of the host speed in the acceleration and deceleration process of the control system of competitive products, and is highly recognized by customers.

4. Reduce the system cost: AX series PLC is based on CoDeSys standardized, open and modularized development platform, with rich instructions and function library integration. It well supports the development of third-party equipment and provides customers with the best control of development cost. Compared with a competitive product, the cost is reduced by 30%.

5. Conclusion

The AX70 series PLC with EtherCAT solution has been successfully applied to the sheet extruder machine. According to the process requirements of various materials, the constant pressure acceleration and deceleration algorithm is used to stabilize the customer core concerned pressure within the target range of ± 0.2MPa, so as to achieve the expected goal and provide a strong guarantee for the high-performance production of plastic sheet extruder machine.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.