Abstract: The stacker is the most important lifting and transportation equipment in the stereo warehouse, and it is a part of the rapid development of the modern warehousing and logistics system. This paper takes the application of INVT GD350-19 special VFD for hoisting in a stacker in a project in Changsha as an example, and introduces the electric drive characteristics of the stacker and the technical advantages of INVT VFD in this application.

Key words: Stacker, Large Inertia, Anti-sway, GD350-19

1. Forewords

The stacker is a symbol of an automated stereo warehouse. Its function is to perform a series of coordinated actions such as horizontal reciprocating linear motion, vertical lifting, and left and right telescopic forks in the roadway, so as to realize the transfer of unit goods between the roadway port conveyor and the designated cargo space. Inbound and outbound operations.

In order to meet the needs of the rapid development of the logistics industry, stacker cranes are developing towards faster walking speeds and higher design heights to achieve higher loading and unloading efficiency and higher space utilization. The resulting shaking of the top of the stacker column has become the first problem to be solved.

Fig.1 Stereo warehouse stacker

2. Stacker technical requirement

The stacker is generally driven by the walking motor through the drive shaft to drive the wheels to walk horizontally on the lower guide rail, the hoisting motor drives the cargo platform to do vertical lifting through the wire rope, and the forks on the cargo platform do the telescopic movement.

Due to the particularity of the mechanical structure of the stacker, the bending moment of the loading platform and the goods on the column during operation, and the horizontal inertial force generated by the acceleration and deceleration of the stacker will cause the column to flex and deform in the roadway plane. The stability and reliability of the stacker's operation make the positioning control of the stacker's walking direction complicated.

The stacker in this project, as the core machine, has a height of 15 meters, a track length of 100 meters, a walking speed of 200m/min, an acceleration of 1m/s², and a positioning accuracy of less than 2mm.

3. Implementation of the control system

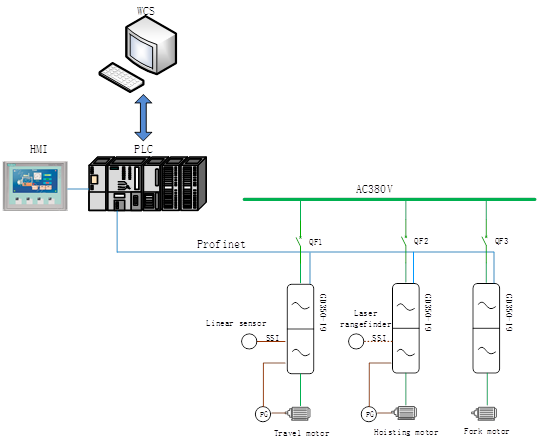

Fig.2 System diagram

According to the control requirements of the stacker, choose GD350-19 series special VFD crane, and realize the customer's technical requirements in the following ways:

(1) System bus: configure Profinet communication card, fully compatible with Siemens PLC bus system;

(2) Fork control: The product adopts advanced vector control technology, and has excellent motor open-loop control performance;

(3) Hoisting control: It is equipped with incremental PG card for speed closed-loop control, and SSI encoder card for full-closed-loop position control. At the same time, GD350-19 is used as a special VFD for hoisting, with complete brake control logic and brake opening torque verification, it can ensure that the car does not slip when starting and stopping.

(4) Traveling control: configure incremental PG card for speed closed-loop control, configure SSI encoder card, read bar code absolute position through SSI signal for full-closed-loop position control;

(5) Anti-sway control: GD350-19 adopts built-in integrated dynamic adaptive anti-sway software algorithm. By adjusting the damping coefficient, the mechanical vibration is reduced to avoid the stacker shaking during the acceleration and deceleration process, realizes the stable start/stop and fast positioning, so as to save the positioning time caused by the shaking of the top after the travel axis stops.

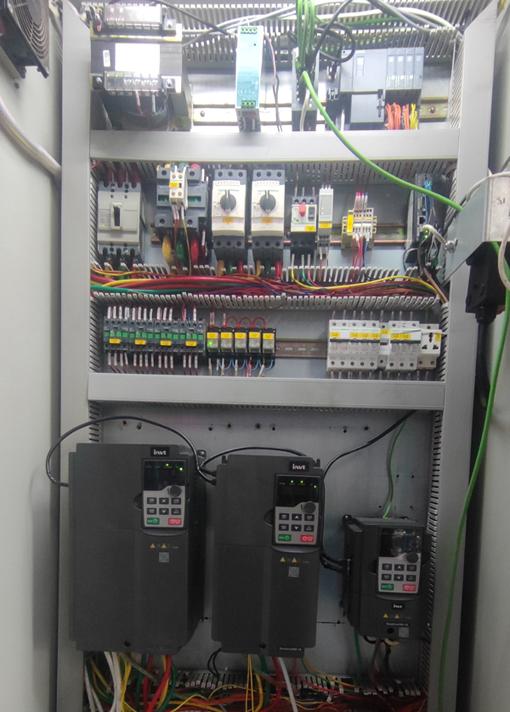

Fig.3 Field site photos

4. Product advantages and operating effects

(1) Dedicated control logic for crane, meets the control needs of stacker;

(2) Strong expansibility, optional PLC card, I/O card, communication card, PG card, power supply card, etc.

(3) Built-in SIL2 level STO safe torque cut-off function, the application is safer and more reliable;

(4) The built-in ANTI-SWAY software algorithm can rely on simple parameter settings to effectively reduce the mechanical vibration caused by high center of gravity and large inertia;

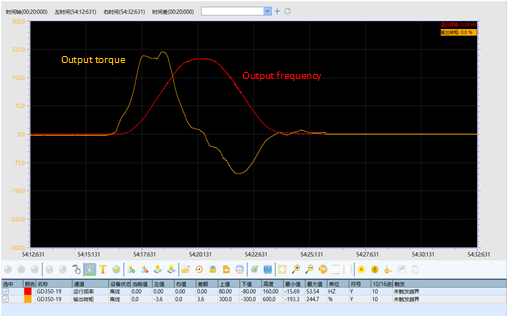

The final commissioning effect can reach a walking speed of 200m/min, an acceleration of 1m/s², and a positioning accuracy of ±1mm.

The speed and torque curve of the stacker when it is positioned on site is as shown in the figure below:

Fig. 4 Operation curve

5. Conclusion

Since the completion of the commissioning of this equipment, the stability, responsiveness and reliability of the stacker can fully meet the customer's requirements through the reliability verification of the customer's long-term operation. It proves that INVT GD350-19 VFD can fully meet the requirements of stacker in terms of performance and reliability

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.