Crane is a multi-action mechanical equipment used to lift and carry heavy objects vertically and horizontally within a specific range. According to the working environment, it can be divided into factory crane, port crane, construction crane, etc.

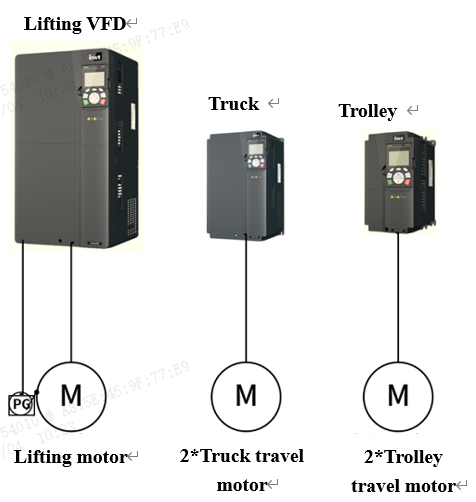

Factory cranes are usually composed of lifting mechanism, trolley running mechanism, and small car running mechanism. The lifting mechanism works through wire rope hanging and winch, and the trolley running mechanism is responsible for moving heavy objects longitudinally and horizontally for position adjustment.

Project requirements

Crane anti-sway technology has evolved from manual, mechanical to electrical. With the advancement of technology, the anti-sway effect has gradually improved and the operation has become easier. At present, crane anti-sway technology is mainly divided into manual and automatic modes. The manual mode solution has low cost, convenient for upgrading old equipment, and great market promotion potential; the automatic mode solution is complex and costly, but the measurement is accurate, the anti-sway effect is good, and it can meet high-demand occasions.

Efficient anti-sway has high requirements on the performance of the VFD:

1. Technical requirements: The VFD needs to have high precision and fast response capabilities, and an anti-sway algorithm to ensure that the shutdown swing is less than 50mm;

2. Operation requirements:

Manual mode: control speed, combined with manipulation, to achieve stable hook and anti-shake effect;

Automatic mode: the load mechanism must be stationary before each positioning, and the VFD automatically reduces the swing amplitude of the hanging object, with the best anti-sway effect, independent of control.

3. Application requirements: Improve the efficiency and accuracy of lifting operations, reduce operating difficulty, and ensure operational safety.

INVT solution benefit

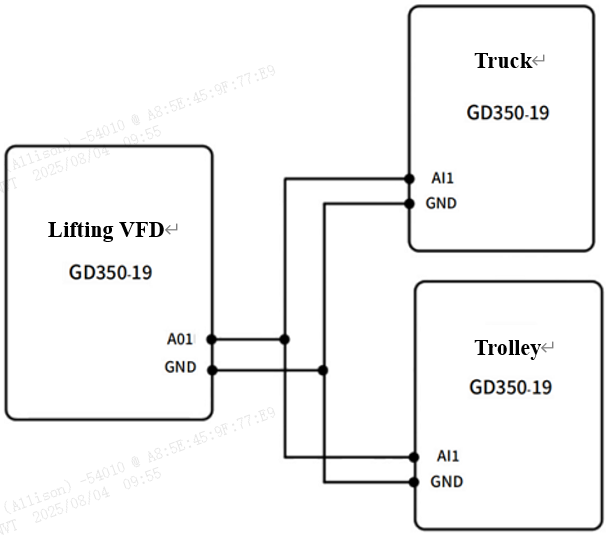

According to customer needs, we provide customers with INVT GD350-19 series crane-specific VFD solutions, with built-in braking unit and anti-sway algorithm, and have the following technical features:

- Support Manual mode and Automantic mode

- Manual mode:The speed is controlled by the driver. After the anti-sway function is turned on, the driver controls the parking distance and reserves the corresponding parking distance for deceleration and stopping. The load hardly swings when stopping. If there is a deviation between the first positioning and the target position, the driver will turn off the anti-sway function and perform micro-movement positioning.

- Automatic mode:The target position is given by the PLC, and the VF has a built-in trajectory generator. Through the generated speed and position information, a mathematical model of load swing is automatically created, eliminating load swing while achieving precise position control.

- Lower carrier frquency control: Lower power dissipation, smaller power selection and lower cost in high-frequency applications.

- Compact desigh: By optimizing the hardware structure, the size is made smaller. Models below 110KW have built-in brake units to save control cabinet space.

Figure 1 Crane anti-sway system solution

Figure 2 Crane anti-sway control wiring

Customer benefit

- Reduce the swing amplitude of hanging objects: The GD350-19 series crane-specific VFD has a built-in professional anti-sway algorithm, making the crane start and stop phases more stable;

- Extend equipment life: Highly efficient anti-sway technology not only improves production efficiency, but also reduces the impact of mechanical shock on equipment load, thereby extending equipment life;

- Enhanced safety: If an operator error causes a malfunction, the system can automatically perform braking protection to avoid safety accidents and reduce equipment failure rate and maintenance frequency, thereby enhancing overall safety and reliability;

- Save time and cost: Anti-sway technology actually helps customers save time and cost. Customers can complete handling tasks faster and reduce downtime caused by equipment failure or maintenance, thereby improving overall production efficiency;

- Improved operational convenience: Anti-sway technology makes the crane easier to operate, reduces the difficulty of operation, enables operators to control the crane more easily, and improves the comfort and convenience of work.

Conclusion

With its excellent performance, INVT GD350-19 series VFD has outstanding performance in crane anti-sway applications, not only meeting customers' strict requirements for accuracy and response speed, but also bringing customers significant economic benefits and productivity improvement through its high efficiency and energy-saving characteristics. Crane anti-sway technology is developing in the direction of intelligence and efficiency, providing strong guarantees for the safety and efficiency of lifting operations. This solution marks an important breakthrough for INVT in the field of heavy industrial cranes, and also provides valuable experience and optimization direction for more industry applications in the future.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.