European cranes are based on the European lightweight and modular design concept and advanced manufacturing technology, making the entire crane compact, running smoothly, with reduced deadweight, lower height, energy saving and consumption reduction, greatly reducing the user's construction cost of the crane operation plant and the crane operation cost. European cranes are a mid-to-high-end gantry crane with the characteristics of light deadweight, compact structure and low energy consumption. They have high requirements for work efficiency, safety, energy saving and environmental protection, and the occasions that require customized functions or equipment have high requirements for the performance of the VFD. The lifting mechanism and the walking mechanism have high requirements for the VFD volume, low speed and high torque and excellent brake logic.

Customer requirements

1.The crane should have a large starting torque, usually exceeding 150% of the rated torque. If factors such as overload tests are taken into consideration, at least 200% of the rated torque should be provided during the starting acceleration process;

2. When the crane lifts the heavy object off the ground, the instantaneous load changes dramatically. The VFD should be able to smoothly control this impact load;

3. Due to the requirements of production efficiency, the crane must have the ability to start and stop lifting quickly, and the VFD must have high stability.

INVT solution

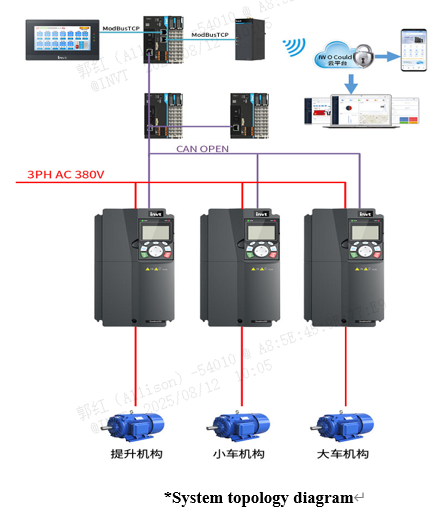

The European crane control system is divided into three modules: trolley control module, truck control module, and cab control module. The trolley PLC TS621 is the master station, the CANopen communication trolley PLC TS611, the cab PLC TS611 and the GD350-19 series VFD, the cab VS-Q series HMI uses ModBus TCP and TS621 for networking, and the IoT Tbox collects system data on the cloud for remote data monitoring, remote program download, and firmware upgrades.

Solution advantages

*Remotely program: VPN virtual network, serial port transparent transmission.

*Remote OTA: Network configuration, program upgrade, status monitoring, and collection strategy.

*Easy to connect: Multiple protocols facilitate interconnection and interoperability. Dual network port design allows for easy cascading and enables isolation of internal and external networks.

*Dedicated brake control logic: The brake logic control integrates torque verification, and releases the brake after the torque is established, which is safe and prevents the vehicle from slipping. The brake logic control supports the starting direction and forward and reverse switching brake selection functions, meeting various starting requirements and having good adaptability.

* Anti-sway function: Adopt sensorless anti-sway control algorithm to realize anti-sway control of various lifting equipment, simple debugging and good adaptability. Standard anti-sway function effectively suppresses the sway of goods during translation and improves work efficiency. High-efficiency anti-sway function effectively reduces the sway of goods during translation and improves work efficiency.

* Loose rope protection: Avoid safety accidents caused by high-speed lifting when the rope is loose, malfunction of the speed increase function, and rope failure.

*3 groups of motor parameters switching: While the motor is switching, we can also switch the application macro. In this way, we do not need to set some functional parameters after switching the application macro at the same time as the motor switching is completed. Even when switching between master and slave modes, the application macro can be switched.

System topology diagram

Customer benefit

*Reduce the swing amplitude of the hoisted objects: The GD350-19 series lifting dedicated VFD has a built-in professional anti-sway algorithm to make the start and stop phases of the crane more stable;

* Extend equipment life: High-efficiency anti-sway technology not only improves production efficiency, but also reduces the load impact of mechanical shock on equipment, thereby extending the service life of the equipment;

* Enhanced safety: If an operator error causes a malfunction, the system can automatically perform braking protection to avoid safety accidents and reduce equipment failure rate and maintenance frequency, thereby enhancing overall safety and reliability;

* Save time and costs: customers can complete handling tasks faster and reduce downtime caused by equipment failure or maintenance, thereby improving overall production efficiency;

* Improved operational convenience: The crane is easier to operate, which reduces the difficulty of operation, allowing operators to control the crane more easily, improving the comfort and convenience of work;

Summary

The application of VFD control makes the crane start-up and braking process smoother, reduces the impact of mechanical shock on the load, effectively protects the equipment, extends the service life, and improves production efficiency. When the crane fails due to operator malfunction, it can automatically perform braking protection to avoid safety accidents, while reducing the equipment failure rate and maintenance times, and enhancing safety and reliability.

INVT has been committed to the creation of electrical transmission product solutions, has rich experience in automation product lines and market applications, and will continue to keep up with the technological development of the industry in the future.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.