Steel pipe forming machines require high-precision motors and transmission equipment to ensure quality standards such as wire diameter and wall thickness of the manufactured steel pipes. The motor cannot shake during the processing process, the machine starts and stops smoothly, and the rigid torque is large, so that the angle of folding is more perfect. The consistency of the length of the processed steel bar and the angle of bending is good, and it is easy to slip when processing smooth steel bars, which affects the accuracy of processing.

Technology process

1. Forming mechanism: the plate edge is pre-bent step by step, so that the plate edge has a curvature that meets the requirements, half of the pre-bent steel plate is stamped into a "J" shape for many times, and then the other half of the steel plate is also bent and pressed into a "C" shape, and finally an open "O" shape is formed.

2. Welding mechanism: make the formed straight seam welded steel pipe seam, and use arc welding to weld on the outside of the straight seam steel pipe.

3. Grinding mechanism: the milling machine mills and polishes the welded edge to achieve the required plate edge parallelism and groove shape.

4.Testing mechanism: the expanded steel pipe is inspected one by one to ensure that the steel pipe meets the test pressure required by the standard.

Pre-bending of front panel edges

INVT solution

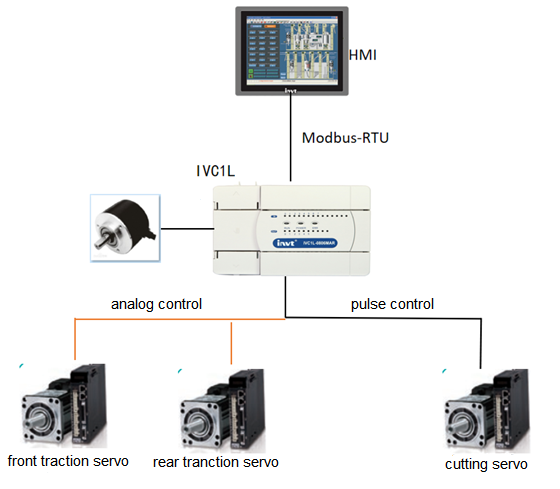

INVT provides a high-performance, new steel tube forming machine servo system solution for process difficulties, which applies the advantages of INVT DA200 series high-performance servo with fast response, accurate positioning, short settling time and smooth operation.

By maintaining the stable speed of the servo motor transmission control of large torque, the steel pipe is formed round, and the load distribution is realized by driving the same load by two transmission points in the front and rear; The front traction servo adopts analog control speed mode, and the speed setting is synchronized with the welder line speed; The rear traction servo adopts analog torque control, and the speed limiting realizes automatic speed adjustment; The cutting servo adopts the second encoder closed-loop position control, controls the motor transmission cutter, and does a fixed-length cut.

Block diagram of the forming machine system

Customer value

1. The servo response frequency is as high as 2.0kHz, which perfectly realizes the speed stability control, and the smooth surface effect of the processed steel pipe is good;

2. The servo system solution can solve the problem of producing a variety of specifications, and is positioned in the high-end industrial steel pipe;

3. The use of rotary encoder is stable and reliable, which can control the cost to the greatest extent and maintain the maximum competitiveness.

Conclusion

INVT DA200 servo has stable overall operation, and the operation effect is higher than customers' expectations for domestic servos. Not only has there been a great improvement in efficiency and quality, but also a great improvement in speed and accuracy. At the same time, it also saves costs for customers, enhances product market competitiveness, and achieves the effect of reducing costs and increasing efficiency. INVT servo solutions are not only used successfully in tube forming machines, but are also suitable for metal forming related control areas.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.