Abstract:

Polytetrafluoroethylene (PTFE) is a Fluoropolymer that has a large number of industrial applications because of its many properties. PTFE industrial coatings are commonly used in mold release applications for products such as golf balls and rubber mats, Alloy wheel, Utensils but can be utilized in multiple applications and uses.

Keywords: AX72, Interpolation Function, Pulse logic, Grouping function

I. Introduction

COATING PROCEDURE:

PTFE coating is the process of coating . This is primarily done with two coats (a primer & a top coat). The PTFE coating is applied to areas where either a low friction, a corrosion-resistant or a dry lubricant is required. To coat a product with PTFE, it will need to be prepared first of all. Particularly preferred are PTFE particles having a maximum diameter less than 30 microns. In conventional or air atomized spraying, the coating is supplied to a spray gun by siphon, gravity, or pressure feed. When the gun trigger is pulled, the coating flows through the nozzle as a fluid stream.

The PTFE particles may be delivered to the surface of the applicator in the dry state, but it has been found to be more convenient to "deliver the PTFE particles to the surface of the applicator in the form of a liquid dispersion. Preferably, the dispersing solvent is sufficiently volatile to evaporate almost instantly, leaving the particles in a substantially dry state.

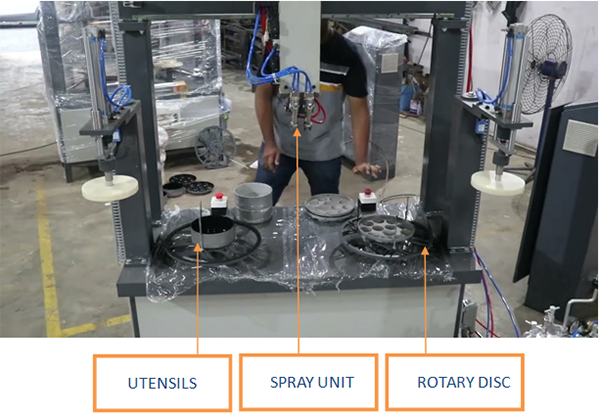

In this machine all the spray unit can be control by 3 stepper motor for linear and coordinated motion. As per the coordinate and angle the INVT motion controller ensure the accurate and fast motion to full fill the application requirements

2. Project information and solution

* Project information

- Site information:

- INVT solution

Product | Model no. | Qty | Application |

PLC | AX72C-1608N | 1 | CONTROLLER |

EXTENSION | AX-EM-0016P | 1 | CONTROLLER |

HMI | VS070QE | 1 | HMI |

* System Configuration

3. System commissioning

Control panels

4. Advantages and benefits

1. Typical film thicknesses are from 10 to 100 microns thick, thick. . A usual characteristic of the process is that the aqueous PTFE coatings are effectively self-limiting in thickness. The quality depends upon the coordinated motion of 3 axis which can be control by INVT AX motion PLC.

2. Teaching more than 100 position and stored in HMI recipe that can be utilized to spray unit as per requirements.

3. Coordinated/synchronized open loop motion with help of PTO/pulse output to make the system more economical and efficient to compete in industry.

This Sleeve Applicator is installed in utensils industry and performance, accuracy and stability all meet the process requirement. We have given INVT solution against Trio motion controller.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.