Abstract: An Automated Metal Sheet Cutting Machine is advanced industrial equipment designed to efficiently and precisely cut metal sheets into various shapes and sizes without manual intervention.

Automated metal sheet cutting machines include increased cutting speed, enhanced precision, material cost savings, and flexibility in design. With help of master encoder, get the accuracy in cutting. System works in fully close loop mode for better accuracy and to reduce wastage of material.

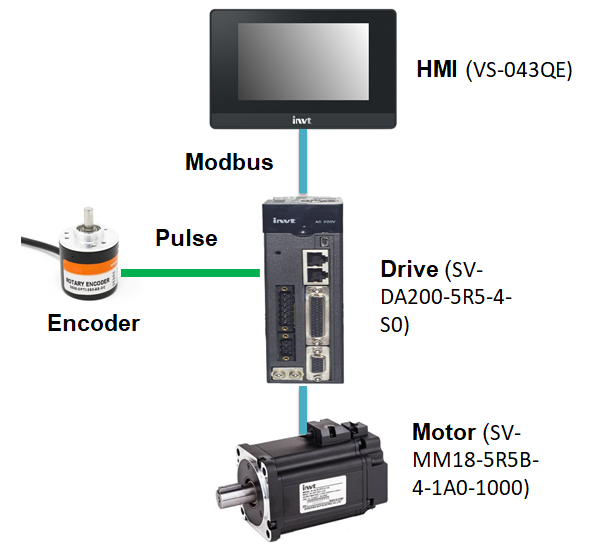

Keywords: DA200, VS HMI, Modbus.

1. Introduction

Machine Procedure:

* Control System:

1. PLC and HMI interface via Modbus communication to set servo speed, cutting length, Jog servo forward speed and reverse.

2. Master encoder connected to servo system to operate in full close loop system.

3. Pneumatic system hold the sheet with help of roller near to master encoder and after command, roller roll it forward with help of servo motor with define set length.

4. Here purpose of master encoder to achieved accuracy in cutting.

5. In this system in feed system not synchronize with cutting machine. In feed speed operate manually.

6. This machine can cut metal sheet up to 3mm thickness.

7. This System can operate in both mode open loop and close loop.

8. In open loop servo consider only servo position but in full close loop servo rotated with help of master encoder pulses which lead better cutting accuracy.

2. Project information and Solution

* Project information

Site information: Steel Industry

* INVT solution

Product | Model No. | Qty. | Application |

Drive | SV-DA200-5R5-4-S0 | 1 | ROLLER |

Motor | SV-MM18-5R5B-4-1A0-1000 | 1 | ROLLER |

HMI | VS-043QE | 1 | CONTROLLER |

* System Configuration

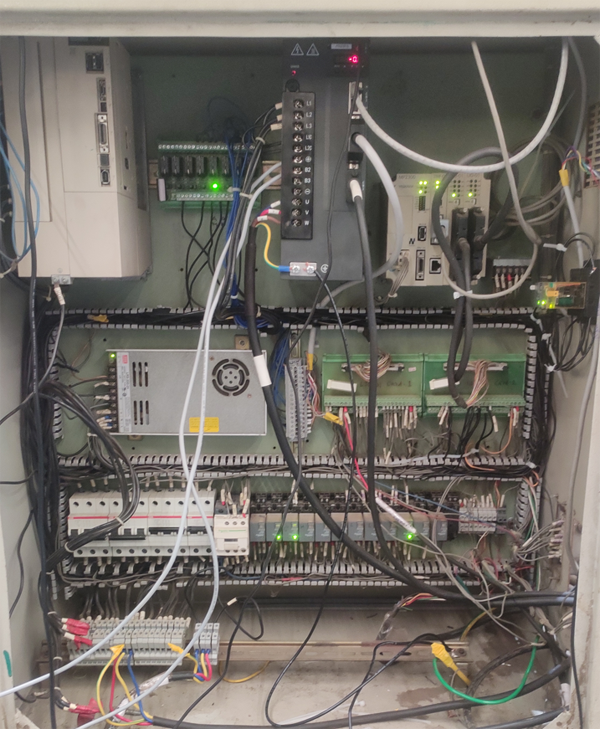

* System commissioning

Control panel

3. Advantages and benefits

1. Easy to communicated with master encoder and servo drive and setting of drive parameters.

2. HMI directly communicated with servo drive via Modbus and possible script function in HMI so easy to program in HMI.

3. Achieved accuracy in +0.01 to +0.03mm which are acceptable in sheet cutting industry.

4. Because of close loop system wastage of material is very less.

5. Automated sheet cutting machines can process materials much faster than manual labor, increasing the overall production rate and throughput.

6. These machines can work 24/7 with minimal downtime, leading to more consistent output and higher productivity in high-demand environments.

7. Since the process is automated, the risk of human error in measurements, positioning, or cutting angles is virtually eliminated.

8. These machines can be programmed to optimize the cutting process, reducing material wastage.

9. Cutting provides cleaner cuts with smooth edges, reducing the need for secondary finishing processes (e.g., deburring or smoothing).

4. Conclusion

This system installed at steel industry. Full close system more accurate than open loop system which achieved the desire accuracy. For that INVT provide solutions against Yaskawa Electric and Siemens.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.