Abstract: Energy saving and emission reduction has become the goal of many factories around the world, the cement industry enterprises are also large users of electricity, according to statistics in the cement manufacturing costs, electricity costs accounted for about 30% of the total cost, so the frequency conversion operation of cement enterprises to reduce production costs and improve production efficiency has a particularly important significance.ID fan for the cement plant production is one of the most important equipment in the cement industry. This article introduces a successful application case of GD5000-S medium voltage drive (MVD) in high temperature ID fan of the cement plant in Karachi, Pakistan.

Keywords: Energy saving, ID fan, Cement plant, GD5000-S, MVD

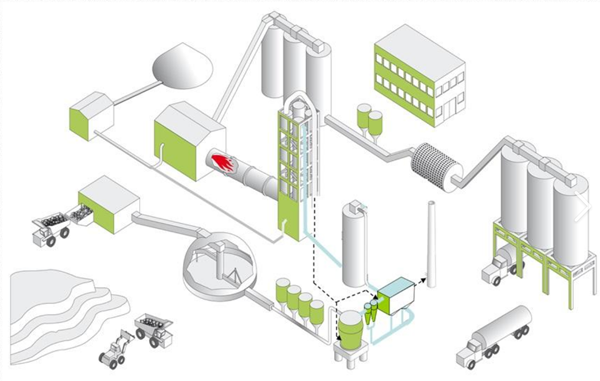

Fig.1 Production process flow diagram

1. Forewords

Cement is a powdered, water-hardening, inorganic cementitious material that hardens in air or water and firmly binds sand, stone and other materials together. With the continuous progress of modern science, there has been considerable development in the cement industry, and different classifications of cement are used for different purposes. The main raw materials for the production of silicate cement are lime raw materials and clay raw materials, and sometimes according to the quality of fuel and cement varieties, mixed with corrected raw materials to supplement the lack of certain components, but also can use industrial waste as raw materials or mixed materials for the production of cement. Cement production process is mainly divided into three stages, namely, raw material preparation, clinker firing and cement grinding.

The high temperature fan is also called ID fan. ID FAN (induced draft fan), which refers to the exhaust fan behind the preheater. There are two types according to the arrangement: one is before the humidification tower, and the other is after the humidification tower.

New dry process kiln production waste heat utilization system high temperature fan, on the one hand, used to adjust the kiln air pressure, on the other hand rotary kiln forging high temperature clinker out of the waste gas with ash, through the preheater into the kiln end before the raw material preheating and homogenization, cooling down the waste heat after the waste heat exhaust, and then through the kiln end of the high temperature fan led by the electric dust collector dust treatment, and then the exhaust off, there is a part of the gas is led to the raw mill on the raw meal A part of the gas is led to the raw mill to preheat the raw material. In some sites, because of the high temperature of the inlet wind of the high-temperature fan, if it is discharged directly, it will cause energy waste, so many sites have added a waste heat utilization boiler to the inlet of the high-temperature fan, and the exhaust gas is discharged after preheating and utilizing, so as to achieve the purpose of energy saving.

2. Project introduction

The project is located in the cement plant in Karachi, Pakistan. INVT provided special Split MDV’s which have modified transformer with input voltage 6kV and output voltage 6kV.

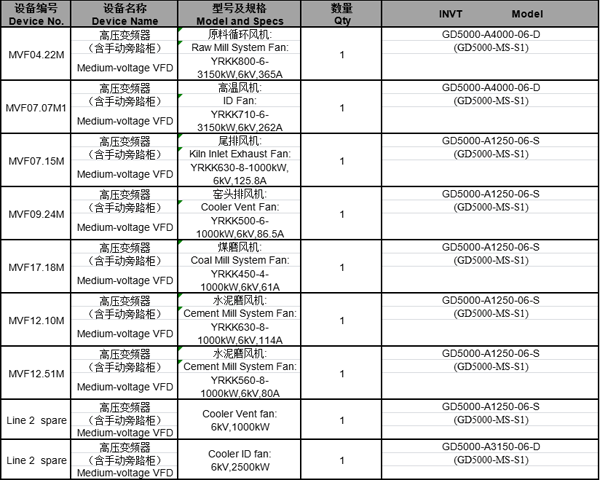

Device information:

Scheme description:

The 6 kV high voltage is input to the inverter, and the output of the inverter is 6 kV connected to the motor. The DCS outputs analog signals to the frequency converter according to the demand of the production sugar volume to adjust the operating frequency. The inverter equipment is connected between the user's high-voltage switch and the motor, and the frequency conversion speed control system is composed of the user's switch, automatic bypass cabinet, GD5000 series high-voltage inverter and high-voltage motor. The automatic bypass cabinet is composed of three vacuum contactors KM1, KM2, KM3 and two high-voltage isolation switches QS1, QS2. When the motor is running in inverter mode, QS1, QS2 and KM1, KM2 are closed and KM3 is disconnected; when the motor is running in industrial frequency mode, KM3 is closed and QS1, QS2 and KM1, KM2 are disconnected, and QS1, QS2 are used for high-voltage isolation in the process of maintenance of inverter. The automatic bypass cabinet is designed in strict accordance with the requirements of “five-proof” interlocking, and the interlocking of inverter output switch KM2 and industrial frequency switch KM3 can completely ensure the safe operation of the inverter speed control system.

Advantages of automatic bypass program:

1) According to the requirements of the system process, it can quickly switch between frequency conversion and industrial frequency to ensure the safe operation of the system.

2) The input and output of frequency converter are designed with isolation knife gate, which is convenient for the maintenance and overhaul of frequency converter.

3) Convenient operation, can be operated locally or remotely, easy to realize automatic control.

MVD system advantage:

* Industrial frequency start-up impact current is large, high requirements on the grid capacity, inverter start-up for the grid zero impact.

* Due to the use of automatic control, and further improve the equipment operation and control and system operation and management of the automation level, so as to truly realize the automatic adjustment, greatly enhancing the safety and reliability of operation.

* The frequency converter has a wealth of I0 ports and protection functions, the use of frequency converter can improve the degree of automation of the compressor system control, improve the safety of the equipment and continuous reliability of the shredding.

* The power factor is increased from about 0.8 to more than 0.95, which eliminates the need for power factor compensation device and reduces line loss. Calculations show that when the turbine is operated with frequency conversion .The annual energy saving is 54.99 million kWh. Electricity saving rate: 41.25 percent

* The frequency conversion output is controlled by PWM technology, the output voltage waveform is basically close to sinusoidal waveform, and the total harmonic amount is less than 2%, and the above indexes satisfy the requirements of IEEE-519 international power quality harmonic standard.

3. Field site photos

Fig.2 Field site photos

4. Conclusion

The energy saving effect is obvious and brings a series of potential benefits after the cement high temperature fan adopts frequency conversion speed control. INVThigh-voltage frequency converter solves the tripping of high-temperature fan due to collapsed material, and the frequency converter runs with high reliability and good operation, which has been praised and recognized by users and operators.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.