With the continuous development of the coal industry, efficient coal transportation equipment is needed in all links, from coal bunkers, coal washing plants to coal storage and transportation. In addition, mines are generally far away from the main production plant, so long-distance belt conveyors have become one of the preferred transportation methods. However, traditional conveying equipment faces problems such as low efficiency and unstable control systems, so long-distance belt conveyors use multi-drive control technology to become the mainstream.

Customer requirements

The newly built South Open-pit Mine of Tianchi Energy Co., Ltd., the Jiangbei Jianger Mine, the Jiangyi Mine, the coal corridor transportation, the diversion station transportation, the silo coal storage transportation and other projects are the key construction projects of the enterprise from 22 to 24 years. Among them, the newly built 150# crushing station to the coal washing plant 152# belt conveyor project has a belt conveyor length of about 4 kilometers and uses 4 medium-voltage permanent magnet synchronous motors with a motor specification of 10000V/630KW. There are 3 motors at the head and 1 motor at the tail.

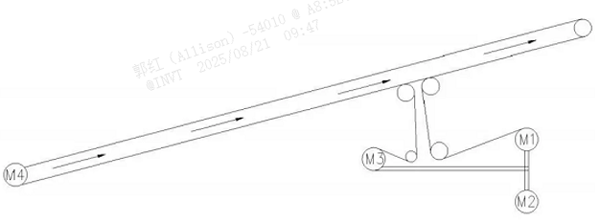

The traditional block diagram of the equipment is as follows:

The motor M1 is the main engine, the motor M1 is coaxially rigidly connected to the motor M2, and the motor M1 is flexibly connected to the motor M3 and the tail M4.

* Multiple motors drive the same conveyor belt to achieve speed synchronization and power balance;

* Ensure that the VFD outputs sufficient output torque during heavy-load starting to ensure starting with material;

* The reliability of long-distance signal transmission, especially the 4 km distance between the head and tail;

* In emergency situations, equipment failure can be controlled through parameter adjustment to achieve 3-drive linkage and maintain uninterrupted production.

INVT Solution

In response to customer needs, the GD5000 series medium-voltage VFD system provided by INVT meets customers' core needs in multi-motor synchronous control, heavy-load starting, etc. through highly integrated vector control technology. It has the characteristics of high efficiency, energy saving and small footprint.

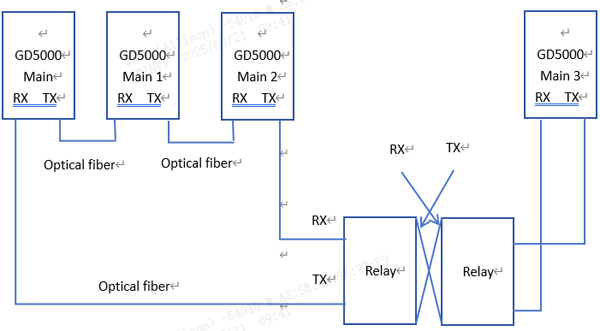

▲Long distance master-slave control block diagram

* High efficiency: Adopt IF starting software to realize heavy-load starting of synchronous motor and avoid the problems of step loss and starting vibration;

* Power distribution and management: Through the optical fiber connection module, reliable transmission of long-distance control signals is achieved, ensuring dynamic response within a distance of 4 kilometers;

* Construction costs: The master-slave speed + droop control technology ensures power balance and speed synchronization of the four motors.

Customer benefit

1. Stable operation

Through the domestic advanced software algorithm, master-slave + droop control mode, real-time speed synchronization and power balance are ensured. In addition, the IF start mode beyond the conventional one solves the problem of synchronous machine overload start, including loss of step, vibration and reversal. The use of optical fiber to transmit control signals ensures fast dynamic response, stability and reliability over long distances.

2. Flexible and safe

The flexible operation mode of 4-wheel drive to 3-wheel drive or 2-wheel drive can reduce the rated load. In addition, the VFD master-slave interlocking protection function can realize the host to quickly identify and stop the equipment when any slave fails. Dozens of built-in protection functions monitor the motor and its own operating status in real time to ensure system safety.

Summary

The successful application and excellent performance of INVT GD5000 series medium-voltage VFD in multi-drive permanent magnet synchronous belt conveyors have proved their high adaptability and reliable value, and have been highly recognized by customers. At present, Tianchi Energy South Open-pit Mine, Jiangjun Next Door Jianger Mine, and Jiangyi Mine have used more than 160 INVT GD5000 series medium-voltage VFD in total, and are the company's strategic partners for large projects. In the future, INVT will continue to uphold the spirit of deep cultivation of industry application technology, and with a complete medium and low voltage product line, strong technical strength and stable product performance, join hands with more industry strategic partners to contribute to the construction of smart mines.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.