Abstract: An industrial washing machine, also known as a commercial washing machine, is a large-scale and heavy-duty appliance designed for use in industrial and commercial settings where there is a need to handle a high volume of laundry on a regular basis. These machines are commonly found in settings such as hospitals, hotels, laundromats, schools, and other facilities with significant laundry demands.

Keywords: INVT D200A-5R5G/7R5P-4

1. Introduction

An industrial washing machine is specially designed for a large-scale operation to ease the washing process faster with low water consumption. Not just are they deployed for fabrics, they work perfectly in industries such as medical, food processing, manufacturing, automotive, and logistics for cleaning and sanitising to make things germ-free.

Some of the industries using washing machines are as follows:

Hotels and Hospitality: Industrial washing machines are widely used in hotels, resorts, and other hospitality establishments to handle the large volume of linens, towels, and bedding that require regular washing.

Healthcare Facilities: Hospitals, clinics, and other healthcare facilities rely on industrial washing machines to clean a significant volume of bed linens, patient gowns, towels, and other medical textiles.

Restaurants and Food Processing: Industrial washing machines are used in the food industry to clean uniforms, aprons, kitchen towels, and other linens. Ensuring hygiene in such environments is crucial.

2. Project Information and Solution

* Project Information: Industrial Washing Machine

Customer Demand – Long gone are the days when hand washing clothes in water was the only option people had. With the technology uprising, we have fabric-specific and industry-specific washing machines to make our lives easier and cater to distinct needs. However, there are a few things that still cannot be cleaned at your home, no matter how excellent or high-quality a washing machine you have.

Solution – This is especially true for those delicate clothes, expensive shoes, or the classy carpet industries. This is where an industrial washing machine comes as an aid for giving an immaculately clean look to your treasured items, which can be washable in mass quantity. With the help of VFD, the washing machine operation can be controlled fully and safely. An operating panel is provided to ON/OFF and vary the speed of the machine.

Site Information:

| Application | Motor Rating | Quantity | Remarks |

|---|---|---|---|

| Washing machine running | 5.5kW, 415V, 14A, 1480RPM, 50Hz, AM | 1 | VF control mode, Frequency reference source is Modbus, 3-wire control |

* INVT Solution

| S.NO | Product | Qty |

|---|---|---|

| 1 | GD200A-5R5G/7R5P-4 | 1 |

GD200A Highlights:

Wall mounting type fixed.

Running in SVM control mode.

Speed controlled through RS485 communication.

ON/OFF controlled via PLC DI/DO.

Drive runs at 80% current under full load.

Acceleration and deceleration times adjustable via drive.

DBR used for braking motor to stop rotation within set time.

System Configuration:

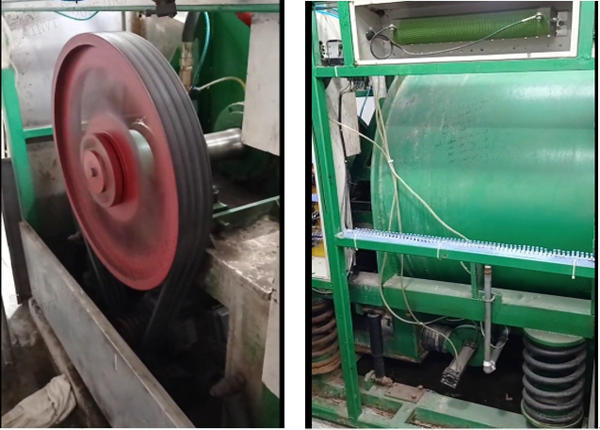

Motor to Rotor Belt Connection Machine Rotor and Body Mounting

3. System Commissioning

Control Panel

4. Advantages and Benefits

It has the function of adjustable acceleration and deceleration time, enabling smooth motor startup, reducing mechanical impact and power grid disturbance, and lowering maintenance cost.

With accurate speed control capability, the user can adjust the speed based on material and output granularity requirements, improving efficiency.

VFD has complete protection functions including over-voltage, over-current, under-voltage, overload, short-circuit, and phase-loss protection to ensure motor stability, reduce vibration and noise, and provide a better working environment.

5. Conclusion

INVT’s solution delivered significant performance improvements in terms of speed, quality, and efficiency. Machine accuracy is improved and speed increased. The GD200A-18G/22P-4 drive inverter is successfully used to run an 18kW motor for the cutting machine under load conditions, with a 50% DBR added for regenerative feedback handling.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.