Recently, iTalent series integrated data center solution from INVT have been successfully applied to the Huazhong Control Center of China Aviation Oil and the comprehensive support facilities project of the Hubei Branch. This solution not only significantly enhanced the service and support capabilities and quality of China Aviation Oil for the aviation and general aviation in Hubei, but also once again demonstrated INVT's outstanding technical strength and the wide applicability of its solutions.

Project background:A New Landmark of China Aviation Oil in Central China

The comprehensive support facilities project of China Aviation Oil's Central Control Center and Hubei Branch is located in the southern working area of Wuhan Tianhe Airport, with a total construction area of 18,800 square meters. As a modern building integrating functions such as aviation control command, comprehensive business management, and a party building base, this project is a core strategic project of China Aviation Oil in the central region. Its data center, as the core hub of control operations, has extremely high requirements for the security, stability, and response speed of the infrastructure.

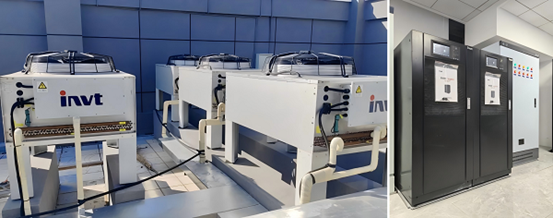

With its advanced technical architecture and stable performance, INVT customized a "highly efficient and flexible + redundant and reliable + cost-effective" iTalent integrated data center solution specifically for the conditions of the computer room. The successful application of this solution not only significantly enhanced the operation and maintenance efficiency, energy utilization efficiency, and data processing capacity of the control center's computer room, but also injected strong impetus into the construction of the dual-hub strategy for civil aviation passenger and cargo transportation in Hubei Province.

Wisdom empowerment:Full-process customization and technological breakthroughs

1. Full-process technology empowerment ensures the precise implementation of the project.

In response to the special requirements of the aviation fuel industry for high safety, strong stability and rapid response, the INVT technical team participated in the technical alignment of the data center construction throughout the process, covering key aspects such as scheme and drawing design, equipment selection, and construction guidance, ensuring seamless connection between project planning and implementation.

2. The core advantages of the iTalent micro-module solution

By adopting the intelligent iTalent micro-module series integrated solution, with the design concept of "efficiency and flexibility + redundancy and reliability + economic applicability", we have achieved three major breakthroughs:

① Reliability upgrade:

* Configure the RM120/30X modular UPS system, combined with a dual bus power supply architecture, and the power supply reliability is enhanced to 99.99%;

* Outdoor unit optimization solution, resolving the problem of excessively long air conditioning piping, ensuring the stable operation of the temperature control system.

② Energy efficiency has significantly improved:

* The closed cold aisle + inter-row air conditioning near-end cooling technology can reduce the annual average PUE to 1.30, and significantly lower energy consumption compared to traditional data centers.

* The intelligent monitoring system dynamically adjusts the cooling capacity and eliminates the loss of ineffective cooling.

③ Cost Optimization:

* The modular architecture enables on-demand expansion, reducing the initial hardware investment for the project.

* The intelligent operation and maintenance system reduces the reliance on human resources and achieves in-depth optimization of the entire lifecycle operation and maintenance costs.

3. Multidimensional Value: Comprehensive Upgrade from Efficiency to Security

After the implementation of the plan, significant benefits were achieved:

* Operational efficiency has soared:

It offers various human-computer interaction methods such as operation monitoring large screens, remote apps, local LCDs, and remote WEBs, significantly improving the response speed of operation control instructions; and greatly enhancing operational efficiency:

* Upgrade of safety performance:

The key system achieves "zero interruption", resulting in a significant reduction in the annual failure rate;

* Significant energy conservation and cost reduction:

Efficient modular architecture + precise cooling by inter-column air conditioning, compared with traditional data centers, can save over 35% of energy;

* Management model innovation:

The intelligent operation and maintenance platform comprehensively covers the scenarios of daily inspections and fault handling, significantly reducing the demand for operation and maintenance personnel.

INVT's iTalent solution not only meets the strict requirements of 7x24-hour uninterrupted operation of the data center, but also promotes the transformation of the management model from "experience-driven" to "data-driven", setting a new benchmark for ensuring aviation energy security.

With the completion of the construction of the China Aviation Oil Central Control Center and the comprehensive support facilities of Hubei Branch, INVT will continue to deepen the innovation of intelligent infrastructure, using digital technology to promote the high-quality development of the civil aviation industry, and helping to build a smarter, safer and greener air energy corridor. With a high-quality and safe energy service guarantee system, it will firmly establish the foundation for regional aviation industry development.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.