1. Background

The paper industry is one of the important pillars of the national economy. It has flourished in recent years with the rapid growth of my country's economy. Pulp production is a key link in the paper process. Production efficiency and quality are directly related to the market competitiveness of paper products. Therefore, bamboo fiber refiner has become an ideal choice for producing high-strength and high-performance paper because of its unique advantage of efficiently converting bamboo into high-quality fiber.

However, with the continuous increase in demand for paper production, customers have also put forward higher requirements on the operating stability and energy efficiency management of refiner.

* Efficient and stable

The refiner needs to have efficient refining capacity and stable operating performance to ensure the continuity and quality of paper production.

* Energy saving and consumption reduction

As energy costs rise, customers hope to reduce refiner energy consumption and improve production efficiency through VFD technology.

* Comprehensive protection

The working environment of the refiner is complex, and the VFD needs to have comprehensive protection functions to ensure the safe operation of the equipment.

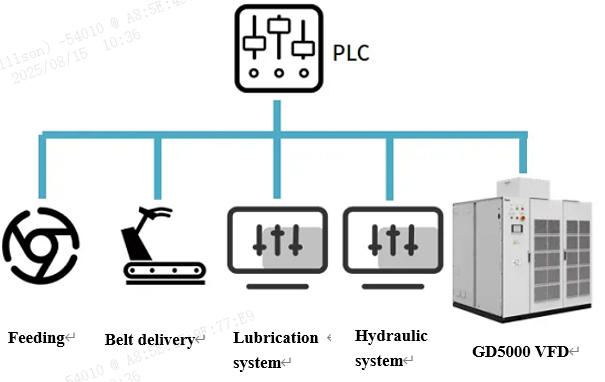

2. INVT Solution

In response to the actual needs of customers, INVT provides them with the GD5000 series medium-voltage variable frequency speed control system solution. The GD5000 series 07 version medium-voltage variable frequency speed control system is an upgraded product based on the GD5000 series 06 version medium-voltage VFD with optimized software, structure, and components. On the basis of continuing the high reliability of the GD5000 series platform, it has a more compact structure, more convenient maintenance, and more complete protection. It can meet the refiner's precise control requirements for speed and torque and ensure the safe operation of the equipment.

1、Mature power unit series connection technology, high power factor and high fault tolerance.

2、DSP+FPGA+ARM triple-core technology, combined with advanced control algorithms, has high control accuracy, fast dynamic response, and high low-frequency output torque.

3、Optimized structural layout + distributed cables, smaller size and better heat dissipation.

4、Touch screen solution upgrade, configuration programming, maintenance is more convenient.

3. Solution advantages

-The starting torque is large, with 1.5 times the torque output at 0.5Hz in open loop, meeting the requirements of the refiner operation;

-It has the advantages of fast torque response speed, and small current fluctuation when the load fluctuates;

-It has good overload capacity and environmental adaptability, and high operating reliability;

-Super strong grid adaptability, the ability to resist grid fluctuations reaches

-15%-+10%, ensuring the stability of output voltage, current and speed.

01 VFD rating parameters

VFD model | Rating voltage | Rating current | Rating power |

GD5000-A3550-10-L | 10000V | 206A | 2800kW |

01 Motor nameplate

Rating voltage | Rating current | Rating power | Rating speed |

10000V | 154A | 2240kW | 1486R/min |

4. Customer Benefit

01 Grid capacity optimization

The customer's power grid capacity is limited, and the VFD is used to achieve soft start of the motor to avoid impact on the power grid and ensure stable operation of the power grid.

02 Reduced maintenance costs

The VFD's comprehensive protection function reduces the equipment's failure rate and reduces maintenance costs. At the same time, the VFD's touch screen solution upgrade and configuration programming make maintenance more convenient.

03 Significant energy saving effect

The VFD achieves stepless speed regulation, with a wide speed regulation range, high speed regulation accuracy and strong practicality. After the frequency conversion transformation, the average power saving rate of customers is about 10%, which significantly reduces energy consumption costs.

5. Conclusion

Facing the dual challenges of energy conservation and emission reduction and quality improvement in the paper industry, INVT has improved the production level of pulping, papermaking and paper products related equipment by leveraging the advantages of high efficiency, stability and precise control of the GD5000, and also ensured the continuity and stability of production, promoting industrial upgrading with lean production strategies. In the future, INVT will continue to deepen the road of technological innovation and product upgrading, provide more high-quality and efficient solutions for the sustainable development of the paper industry, and work with customers to create a new chapter of green and intelligence.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.