Background

Pulp pumps are essential key equipment in industrial production and are widely used in industries such as papermaking, sugar making, mining, chemical industry and sewage treatment. They are specially used to transport pulp or other high-viscosity and high-abrasive fluids containing solid particles (such as fibers and abrasives). However, traditional motor drive systems have problems such as high energy consumption, large losses and high maintenance costs, which make it difficult to meet the needs of modern industry for efficient, energy-saving and reliable operation. Therefore, seeking a new type of efficient and energy-saving drive solution has become an urgent need for industrial enterprises.

Customer Request

An Indonesian company made the following specific requirements for upgrading the drive system on its pulp production line:

* Simple control : The system needs to have excellent starting characteristics and speed regulation performance, and large starting torque to adapt to the operating requirements under different working conditions.

* Energy saving : The drive system needs to have significant energy saving effects to reduce long-term operating costs.

Reliable operation : The system needs to have high reliability, low maintenance, and reduce downtime and maintenance costs.

* High cost performance : Under the premise of meeting performance requirements, it must have a high cost performance.

* Ensure the quality of VFD output : The distance between the motor and the driver is 250 meters, and the output quality of the frequency converter (VFD) must be stable and reliable.

INVT Solution

In response to the specific needs of customers, INVT proposed a drive solution based on GD350A inverter and synchronous reluctance motor (SynRM). This solution has the advantages of high efficiency and energy saving, excellent control performance, and convenient maintenance.

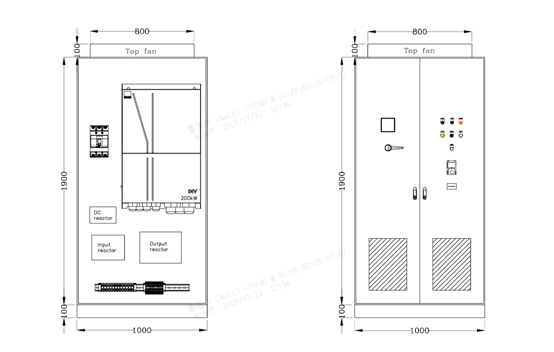

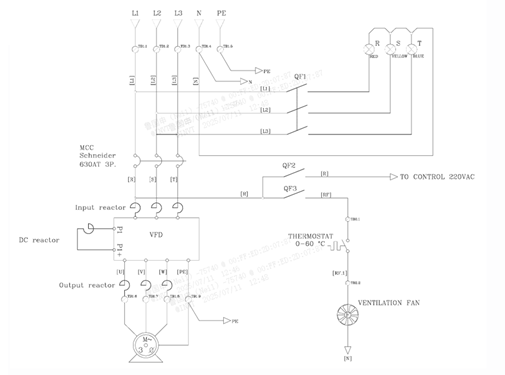

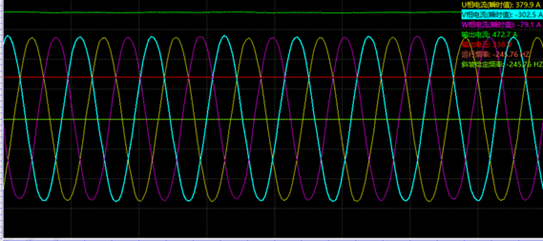

The GD350A series inverter is used to support various motor controls such as asynchronous, permanent magnet synchronous, and synchronous reluctance. The control algorithm is upgraded and the motor control performance is greatly improved. The synchronous reluctance motor is rugged and reliable, energy-efficient, has a wide speed regulation range, and is easy to maintain. There are no permanent magnets on the rotor, so there is no risk of demagnetization and the efficiency is stable in the long term. The GD800 PRO cabinet is used with built-in DC reactors, input reactors, and output reactors to ensure the long-distance output quality of the VFD and meet the requirement of a distance of 250 meters between the motor and the drive. Combined with the latest synchronous reluctance motor control algorithm, it has excellent control performance, large starting torque, good speed regulation performance, and significant energy-saving effect.

Customer Benefits

* High efficiency and energy saving : The combination of synchronous reluctance motor and GD350A inverter significantly improves the working efficiency of pulp pump, reduces energy consumption and reduces enterprise operating costs.

* Stable and reliable : The system operates stably and has excellent control performance, which reduces downtime and maintenance costs and improves production efficiency.

* Long-distance drive : By integrating DC reactor, input reactor and output reactor, the long-distance output quality of VFD is guaranteed, meeting the requirement of 250 meters distance between motor and driver, and improving the flexibility and applicability of the system.

Summarize

The application case of INVT GD350A driving synchronous reluctance motor in pulp pump fully demonstrates INVT's technical strength and mature solutions in the field of synchronous motor control. Practice has proved that this solution fully meets the customer's use requirements and brings significant economic and social benefits to customers. Relying on a complete high, medium and low voltage product line, INVT has mature and complete full-process solutions and has accumulated rich technical experience. It will continue to provide efficient, energy-saving and reliable drive solutions for the field of industrial automation.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.