Super calender is one of press polishing equipment in paper making. Its shape is similar to calender with a larger number rollers. The super calendar applies to coated paper, enamel paper, writing paper, offset printing paper and other cultural paper and insulation paper such as capacitor paper.

The working principle of super calendar

When the Paper touch hot roller in the running, the hot roller pass the heat energy into the paper in a short time, and when the heat energy reaching certain critical depth(usually considered as 0.007μм) ,the temperature of the paper surface reaches or near glass softening point , the plasticity of the paper is strengthened at this point. Then soft roller appears elastic deformation in compression, the pressure area formed surface contact. The hard roller whose surface looks like a mirror makes the plasticized paper smooth and shiny and retains appropriate thickness that is similar to the function of molding press machine.

Supercalender belongs to specialty paper processing equipment, domestic machine is commonly equipped with foreign famous sensor+ VFD +PLC as standard, INVT VFD has changed the situation that foreign product monopolies the super pressure paper industry all the time.

INVT’s solution: adding high-tech at R&D laboratory

Customer requirements: fast, flat, stability while during acceleration and deceleration.

Linearity of acceleration and deceleration: customer demand the processed paper can start up with staples shift between 0~480m linear speed, and in the processing of shifting speed, the paper can’t appear fluctuation and fracture.

Meet various complex processes: meet the demand of various paper processes,there are a variety of paper varieties and different quality requirements for various products, so the process conditions are different. The wide range of 80g/M2~17g/M2 (the thickness of single-sided toilet paper) includes the late water spray humidification process.

Low cost and high cost performance: with automatic and accurate calculation of coil diameter PID compensation function, no appearing paper broken, short instant-quick shutdown time, no waste of material or damage of paper track, and total cost is lower.

Solution explanation

Base on customer requirement, Invt issues star product— GD350 series ,high-performance and multi-function VFD with tension PID function, meanwhile considering wind control, the host machine uses high-performance,GD200A series, general purpose open-loop vector control VFD.

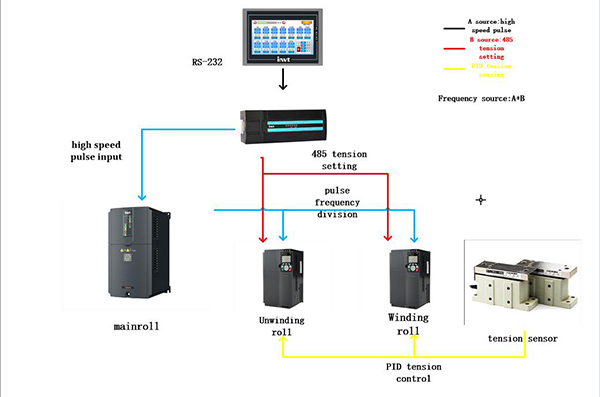

System scheme framework

Inverter control scheme architecture diagram

Electric control cabinet

Left side of cabinet

GD350 (37kW) is unwind control within Frequency conversion and tension sensor, which insures the flat of speed of unwinding and keep the constant of tension on time.

GD350 (15kW) is wind control within Frequency conversion and tension sensor, which insures the flat of speed of winding and keep the constant of tension on time.

Right side of cabinet

GD200A (160kW) is the host machine which is used to provide frequency –dividing pulse to the main gear adding S-curve to wind control, which can make order output smooth.

Application picture

The advantage of Invt’s solution

Advanced function of algorithm used to control tension of unwinding

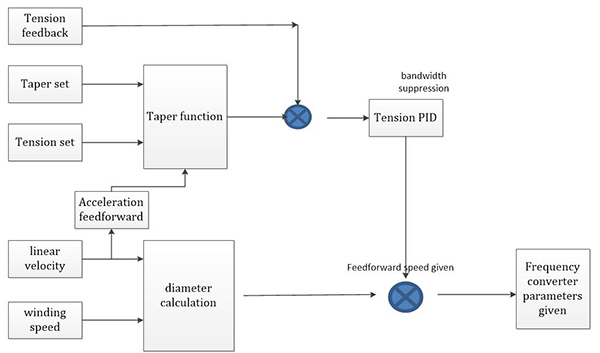

The GD350’s advanced dedicated unwinding mode having automatic calculation for roll diameter and tri-output ports of PID automatic tension adjustment, which insures the tension of the thinnest 17g/M2 (the thickness of single side toilet tissue) output constant, fast, stable and fluctuate uneasily.

More advanced than Master-slave following function

In the situation that unwinding follows the pulse from the host machine, GD350 receives analog signal from external tension sensor and uses PID regulatory function of P09 group, the function makes winding follow the host machine accurately, keeps the tension and prevents 17g/M2 paper to be broken.

The LCD keypad interface makes debugging convenient

LCD keypad has Chinese/English parameter description, monitoring current, voltage, speed, torque and other parameters all the time, making debugging convenient and observing state of the master-slave following.

Adding high-tech at R&D laboratory

Inertia Reverse compensation function: In the situation that using standard friction and inertia compensation, unwinding control may not provide enough tension when the roll diameter is very small, the PID couldn’t make work at this time. So it’s necessary that roller of unwinding involves unwind process actively which can make reverse compensation to torque, then operation of paper is more smooth.

Summarize

Super calender belonging to specialty paper processing equipment is a high-end machine for processing paper, the price of imported equipment is generally above one million. INVT who uses GD350 in super calender paper machinery that breaking foreign industry monopoly and fills the gap of domestic frequency conversion in the application of high-end equipment is an innovator who has the courage to try new things.

Besides, INVT has complete system solutions, which can fully assist the production of domestic paper processing machinery in other paper processing, for example, corrugated paper : cross cutter ,slitter machine ,toilet paper :slitting and rewinding, A4:the fixed length cutting ,slitting and rewinding

In the future, INVT will continue to provide more systematic and efficient paper processing industry system solutions to help domestic and foreign manufacturers grow rapidly.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.