1.Forewords

Due to different geological conditions of coal mine, the belt conveyer has lane transport, upward and downward. Due to the gravity of the material and belt, during downward working, the mechanical energy is converted into electrical energy and fed back to the motor and drives. If some of this energy is regenerated to power grid, the coal mine energy saving will be very beneficial.

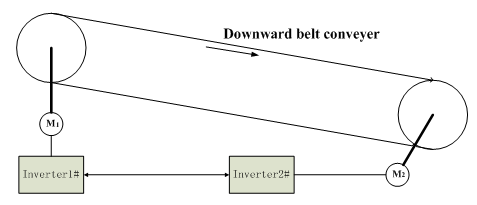

Different to lane transport and upward, the variable frequency inverter of downward belt conveyer, not only need to solve the power balance of multi motors, but also need to control the fed back energy. This paper describes INVT Goodrive3000 (referred to as GD3000) four-quadrant inverter in Shanxi, a coal mine site applications.

2.Project introduction

Fig.1 System diagram

Parameters of belt conveyer:

| Volume | Belt speed | Belt width | Length |

| 1000t/h | 3.5m/s | 1.0m | 650m |

| Angle | Motor power | Motor voltage | Motor type |

| 19° | 280kW | 1140V | Asynchronous |

Fig.2 Belt conveyer

Fig.3 Motor and reductor

3.System scheme

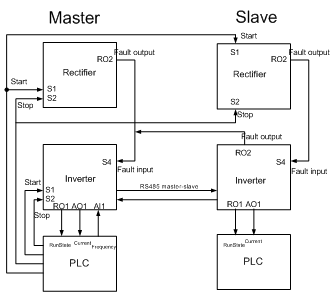

It is a downward belt conveyer with big angle, it needs four-quadrant inverter, we choose 2 pieces of GD3000-11-400G-12 with explosion-proof shell. Two inverters use master-slave control, to make sure the two motors work at same speed and same power. And they can regenerate the power to grid.

Fig.4 Schematic diagram of master-slave control

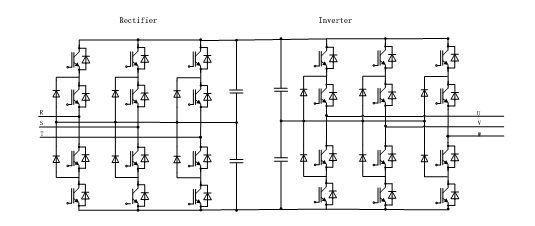

Fig.5 GD3000-11 3-level and four-quadrant inverter diagram

4.Advantage

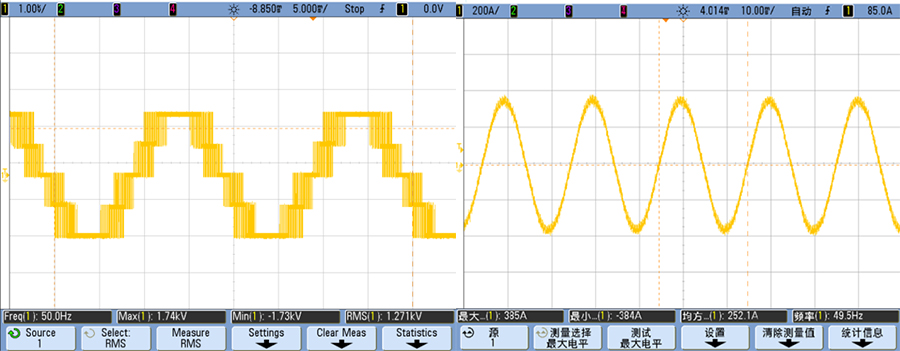

1)Output waveform is better than 2-level inverter, more similar to sine wave

Fig.6 Output voltage waveform Fig.7 Output current waveform

2) Low dU/dt, low peak voltage to motor, reduce damage to motor insulation

3) Low common mode voltage, low shaft current of motor, reduce damage to motor shaft

4) Lower harmonic under same carrier frequency, THDi <5%, THDu <3%

5) Long life design- use film capacitor

6) Multiple protection functions, ensure system reliability

5.Site photos

Fig.8 GD3000-11 with explosion-proof shell

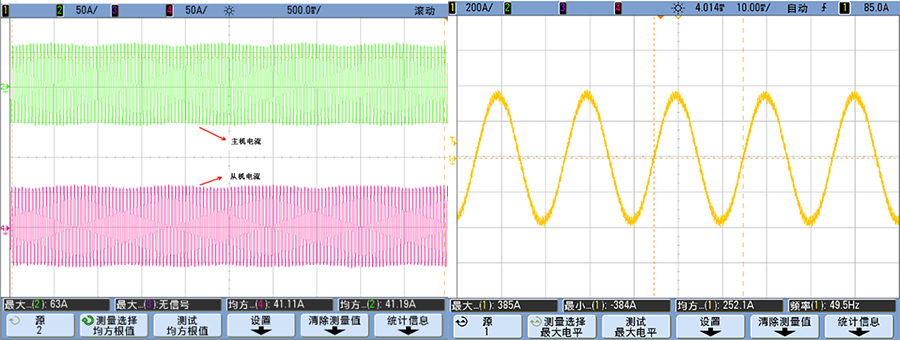

Fig.9 Output current Fig.10 Input current

6.Conclusion

The application of Goodrive3000 on downward belt conveyer, successfully solved the problem of regeneration of fed back power. It has a very active role for the coal mine automation upgrade and energy saving, it is worth promoting. INVT is committed to the mining enterprises of automation and energy efficiency control to provide a complete solution!

Reference

(1)Shenzhen Invt Electric Co., Ltd. < Goodrive3000 Series Inverter Operation Manual >• 2015

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.