Abstract: Compared with the traditional water tank and water supply by water tower, variable frequency constant pressure water supply has many advantages like energy saving, no pollution to water resources and so on. In this paper, we will take constant pressure water supply by pumps driven by one GD200A series inverter in a water supply plant as an example, to illustrate the details of application of INVT GD200A series inverter in constant pressure water supply.

Keywords: GD200A, Water Pump, Constant Pressure Water Supply, Pumps Driven by one GD200A series inverter

I.Introduction

The water supply automatic control system is working while the equipment is detecting the pressure change caused by water consumption change of water supply network through high sensitive pressure sensor installed on water supply network, which can constantly transmit change signals to inverter. The inverter will send signal to change frequency after comparing the result calculated by micro-computer and the setting pressure value.

The controller can change rotate speed and decide the using number of water pump. It can automatically adjust water supply volume at peak and valley to ensure that the water supply network pressure is constant so as to satisfy water demand of users.

II. Control Requests

This paper will illustrate the control demand of INVT GD200A series inverter applied in a constant pressure water supply plant. This is shown in figure 2. And the specific control requests are as follows:

● The system requires 2 sets of 4kw inverter to control pump to achieve constant pressure water supply, which one inverter can control up to three pumps. The requests to inverter are as follows:

a) PID control can achieve constant water supply pressure.

b) One inverter can drive 2 to 3 pumps. In this way, the investment of equipment can be reduced and the automatic switch between variable frequency pump and power frequency pump can be achieved.

c) G / P syncretic function are flexible for different loads to switch.

d) Strong overloads capacity and stable operation.

e) Compact and easy installation.

Figure 2 the Control Demand of INVT GD200A Series Inverter

III.INVT GD200A Series Inverter Introduction

Based on DSP control system, GD200A frequency drive apply V/F vector control technology and various protections to control asynchronous motors in an excellent driven way. The air duct design, hardware configuration and software have been greatly improved for better usability and environment adaptability. Its reliable quality was certificated by TÜV SÜD, providing strong guarantee for our customers to use.

A.Technology Features:

1. Frequency setting mode: digital setting, analog setting, pulse frequency setting, serial communication setting, multi-step speed and simple PLC setting, PID setting, etc., which can switch setting combination and modes.

2. The motor parameter self-study in a rotate or static state can be completed. Easy to debug and operate. Provide higher control accuracy and response speed.

3. Vector V/F control performance.

4. Easy water supply function can make 3 pumps driven by one inverter so as to control water supply in a constant pressure.

5. Good voltage and current control function can effectively reduce the frequency of protection of the inverter.

6. Provide a variety of braking methods to realize quick stop.

7. Higher over-temperature point of the machine is more suitable for textile industry under the high temperature environment.

8. Speed tracking restart function can achieve free impact smooth start of the rotating motor.

9. Automatic voltage adjustment function. It can automatically maintain the constant output voltage when the grid voltage changes.

10. The inverter system is of multi-protection for over current, over voltage, voltage shortage, over temperature, phase loss and over load.

IV. System Wiring and Debugging

The system is set with easy technological parameters, which can monitor in real-time and record official website pressure for later data analysis. There are two inverters and each of them can control 3 pumps to supply water in a constant state.

A.There are several technology features when debugging:

First, confirm the feedback source and use PID to control travel closed-loop.

Second, adjust PID parameter to make small fluctuation on pipe network pressure.

Third, set pumps switch parameter to switch accurately, timely and normally.

● Input inverter parameter, frequency given way and acceleration or deceleration time.

● Access to feedback source voltage signal. Observe its measurement scope by parameter and properly correct the parameter in P5 group.

● Single pump operation constant pressure control and adjust the PID parameters, which make low voltage vfd fast and stable at the set value.

● Set the pumps switching function parameters to meet the process requirements.

● Observe system stability with a long time.

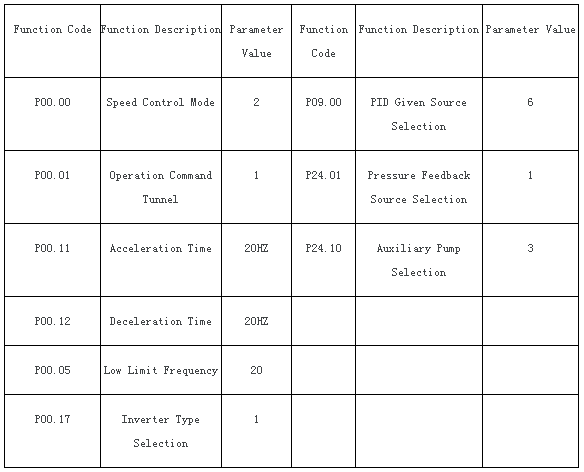

B. Inverter Parameter Setting

Part of inverter key parameters is shown in table 1.

Table 1: GD200A Parameter Setting Table

The inverter system is of multi-protection and fault output function for short circuit, overload, overvoltage, phase loss and stall, etc., to effectively ensure the safe and efficient operation of the system.

V. Conclusion

Application of variable frequency control technology in the field of constant pressure liquid supply and increase of the special control module give an optimized constant pressure water supply program to market. This special inverter assembly water supply automatic control system has the characteristics of low investment, high degree of automation and complete protection function. The inverter is reliable, easy to operate, water-saving and energy-saving, especially no secondary pollution to water quality, which is of excellent performance and low cost.

References

[1] "Goodrive 200A inverter product brochures" Shenzhen INVT Electric Co., Ltd.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.