1. High efficiency and energy saving:

* High-efficiency variable-frequency components: The system is equipped with DC variable-frequency compressor(s) and high-efficiency EC fan(s). Its operating parameters are PID-controlled based on system load, ensuring that it consistently operates within the high-efficiency range.

* Variable-frequency refrigerant pump heat pipe technology: The entire unit adopts this technology, which makes full use of free cooling sources when outdoor temperatures are low, significantly reducing power consumption.

* Free cooling priority strategy: The system prioritizes free cooling during transitional seasons. When free cooling is insufficient, the system will activate the compressor to provide supplemental cooling, maximizing the use of free cooling sources.

* Spray cooling: Optional spray components can be installed near the main unit dual-circuit condenser to utilize evaporative cooling technology, reducing condensing pressure and improving operational efficiency. Spray cooling also raises the temperature threshold for entering free cooling mode, further enhancing annual energy efficiency.

2. Comprehensive and reliable:

* 100% fluorocarbon system: Both the main unit and terminal units use fluorocarbon as the heat transfer medium, with no water entering the server room. This eliminates the risk of freezing during winter operation.

* Multiple redundancy: On-site redundant main unit installation, featuring multiple compressors and multiple refrigerant pumps. This design effectively minimizes the impact of single component failures on the entire system, enhancing overall operational reliability.

* Intelligent dual-circuit design: The main unit employs dual-condenser technology, with the free cooling system and the mechanical cooling system operating independently. The mechanical cooling system circulates refrigerant only within the main unit, enhancing compressor reliability.

* Plate heat exchanger: The main unit uses a plate heat exchanger to transfer heat between the compressor and terminal circuits, enabling stable circulation of the terminal refrigerant over long distances and large elevation differences.

* High IP rating: The main unit meets the IPX5 standard and features UV-resistant cable routing, ensuring reliable operation in various outdoor environments.

3. Intelligent control:

* Equipped with a 7-inch touchscreen providing a multi-functional human-machine interface (HMI) with an elegant, user-friendly design and smooth operation.

* Capable of real-time display of operating pressure curves and monitoring of all operating parameters, with alarms and corresponding protective actions for abnormal parameters or component faults.

* Three-level password protection on the display with hierarchical access control.

* Standard dual interfaces: RS485 and SNMP, supporting remote monitoring.

* Supports CAN bus networking for up to 64 units.

4. Diverse terminal options:

* Room-based air conditioner: Cooling capacity range: 30–120kW. Installed inside the server room to control the temperature. Modular design for easy installation and capacity expansion.

* Rear-door air conditioner: Cooling capacity range: 3.5–15kW. Installed on the rear door of the cabinet and close to the load. It cools the hot air from the load and discharges it into the server room.

* In-row air conditioner: Cooling capacity range: 15–40kW. Installed between cabinets and close to the load. It cools the return air and delivers it directly to the cabinet load.

* Above-rack air conditioner: Cooling capacity range: 7.5–20kW. Installed on top of the cabinet and close to the load. It cools the hot air from the load and discharges it into the server room.

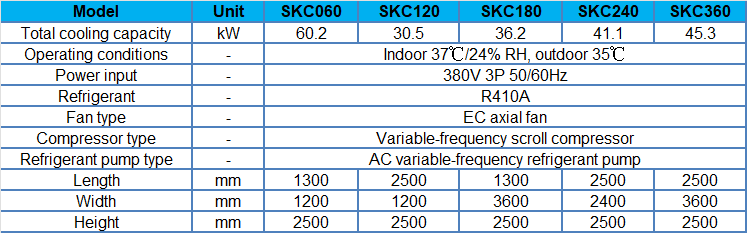

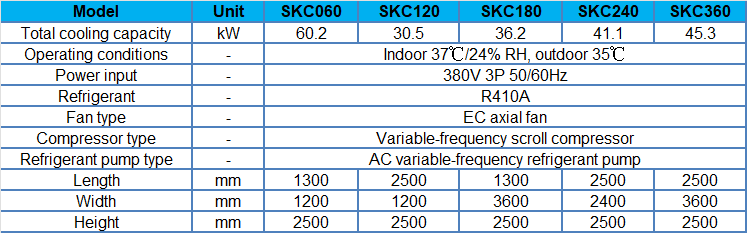

Specifications:

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.