1. Project Background

Thailand is a core aquaculture producer in Southeast Asia. High-density fish and shrimp farming has extremely high requirements for the continuity of water aeration and exchange, which consumes a large amount of electricity and increases the production costs of fishermen. Meanwhile, the local area has a long rainy season and high humidity, making equipment vulnerable to moisture and dust erosion.

With its technical features of "efficient PV MPPT control algorithm, dustproof and waterproof design, and AC-DC complementary input to support 24/7 continuous operation", the INVT SP100 PV Water Pump Inverter is adaptable to the complex environment of Thai aquaculture. It provides stable and clean power for fish ponds, helping local aquaculture achieve efficient and low-carbon upgrading.

2. Customer Challenges

A large-scale fish and shrimp farming based in Thailand faces multiple operational pain points:

* High operational costs: The aeration system needs to operate continuously, consuming a large amount of electricity and driving up aquaculture costs.

* Poor environmental adaptability: In the high-humidity and salt-spray-rich environment of fish ponds, conventional equipment has insufficient protection level, leading to high failure rates during the rainy season. Frequent shutdowns cause water hypoxia and reduce fish and shrimp yields.

* Insufficient PV stability: Although pure PV power supply can significantly reduce municipal electricity consumption and save energy, it is greatly affected by weather conditions, making it impossible to ensure the operation of aeration equipment on cloudy days and at night.

Customer's core requirements: A power system that is easy to install, adaptable to high-humidity and salt-spray environments, and supports complementary PV and municipal power supply. It should ensure the 24/7 stable operation of aeration equipment while reducing long-term operational costs.

3. INVT Solution

To address the customer's needs, INVT provides an aquaculture power solution centered on the SP100 PV Water Pump Inverter:

* Easy installation design: The SP100 is equipped with plug-and-play waterproof terminals, allowing fixation without professional tools. Its high-protection design eliminates the need for an electrical cabinet, greatly reducing installation time and costs.

* High protection performance: With an IP66 protection level, the SP100 can be directly adapted to the harsh high-humidity and salt-spray environment of fish ponds, effectively preventing equipment failures caused by moisture and dust intrusion.

* AC-DC complementary input: The SP100 supports "PV + grid" dual-power complementary input. It prioritizes PV power supply on sunny days and switches to complementary power supply on cloudy days and at night, ensuring 24/7 continuous operation of aeration equipment.

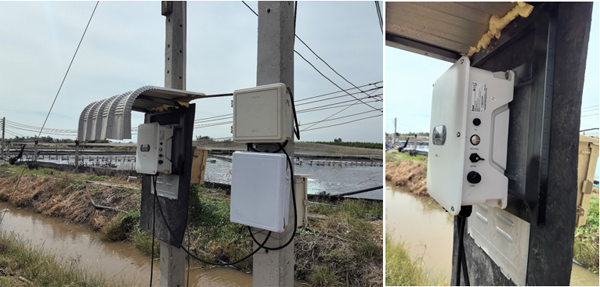

As shown in the on-site pictures: The SP100 is conveniently wall-mounted on the concrete pole bracket of the fish pond. The equipment housing has no exposed interfaces and maintains stable operation in high-humidity environments. The AC-DC complementary input module ensures the continuous operation of aeration equipment, keeping the dissolved oxygen in the fish pond water within an appropriate range.

4. Customer Benefits

* Guaranteed power stability: The AC-DC complementary input function completely solves the intermittency problem of pure PV power supply, achieving a 100% continuous operation rate of aeration equipment.

* Reduced operational costs: After replacing diesel with PV power supply, the annual energy cost per fish pond is saved by more than 45,000 Thai Baht. The AC-DC complementary mode reduces reliance on grid electricity, lowering the comprehensive operational cost by 40%.

5. Conclusion

With its core advantages of "easy installation, high protection, and AC-DC complementary input", the INVT SP100 PV Water Pump Inverter accurately meets the scenario requirements of Thai aquaculture. It not only solves the cost and stability problems of traditional power sources but also adapts to the harsh high-humidity and salt-spray environment. In the future, INVT will continue to deepen the technical adaptation of PV water conservancy in the aquaculture field, providing reliable solutions for the green and efficient development of the global aquaculture industry.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.