Recently, exciting news emerged from a large aluminum plant in Southwest China under China Aluminum International (CHALCO): INVT GD880 series inverters have successfully completed a seamless, full-scale replacement in the variable-frequency speed control system for diaphragm pumps used in the plant's alumina production. This marks a significant domestic breakthrough in core process drive technology for alumina manufacturing.

Currently, the upgraded system is operating stably with excellent performance across all key indicators, signifying a major technological advancement for high-end domestic inverters in critical industrial applications.

Process Introduction

Alumina Production

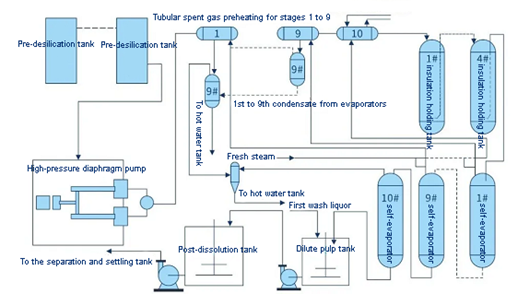

In the initial stage of alumina production, bauxite is crushed and mixed into a raw ore slurry, which is then pumped to a high-pressure digester using a diaphragm pump. Under specific process conditions, the leaching rate directly determines the alumina output: when leaching time is constant, a faster leaching speed results in higher production capacity. Therefore, the stable operation of the diaphragm pump is a critical factor in ensuring production continuity and product quality.

Customer Requirements:

The aluminum plant faces numerous challenges in the process of alumina production, imposing stringent requirements on the VFD system:

Aging Equipment Issues: The existing branded equipment has been used for many years, showing severe signs of aging with a high failure rate, leading to frequent production interruptions. Additionally, the cost of spare parts is high, and the procurement cycle is long, significantly impacting the normal operation of production.

Operational Stability Issues: During operation, the diaphragm pumps experience significant pressure fluctuations and unstable speeds, resulting in uneven slurry delivery, which affects the leaching effect and the yield of alumina.

Requirements for Reliability and Stability: The stability of the diaphragm pump system is directly related to the continuity of the entire production process and production safety. A failure could lead to the paralysis of the entire production line, causing substantial economic losses.

Informatization Needs: With the development of industrial automation, the aluminum plant has put forward higher demands for reading various equipment statuses and adapting capabilities to fieldbuses. The requirement for informatization is increasing.

INVT Solution

In response to the aluminum plant's detailed requirements, INVT has introduced the GD880 VFD solution. This solution not only ensures seamless performance integration but also significantly optimizes operation and maintenance costs, offering the following advantages:

1. Uses internationally mainstream standard core components, ensuring high performance and reliability of the VFD.

2. Achieves closed-loop speed control accuracy of ±0.01% and torque response within 5ms. The high speed stability and fast torque response effectively solve the problems of large pressure fluctuations and unstable speed in diaphragm pump operation.

3. Features a wide voltage range design (-15% to +10%), advanced "anti-voltage sag" technology, precise fault prediction and handling algorithms, as well as modular design and fault derating functions. These enhance system reliability and stability, ensuring stable operation under various harsh conditions.

4. Equipped with a remote IoT interface and customizable status word/control word functions, supporting domestic industrial upgrading. It also meets the plant’s informatization needs for reading multiple equipment statuses and compatibility with fieldbus communication.

Customer benefits

1. Cost Reduction

INVT GD880 VFD effectively reduces the plant's equipment procurement costs. Its modular and maintenance-free design minimizes system complexity, shortens installation and commissioning time, and reduces maintenance costs by over 40%.

2. Improved Production Efficiency

High speed stability and fast torque response ensure stable operating pressure, increasing slurry leaching efficiency by 2% and boosting alumina output, thereby enhancing the plant's economic returns.

3. Significantly Enhanced Reliability and Stability

System reliability and stability are improved by more than 20%, effectively reducing equipment failures and downtime, ensuring continuous and safe production.

4. Compatibility and Informatization Upgrade

Offers excellent performance and seamless compatibility with other brands, facilitating equipment upgrades and retrofitting. The remote IoT interface enables remote maintenance and centralized management, meeting the plant’s informatization upgrade needs and improving operational efficiency.

This successful project by INVT shows that high-quality Chinese-made VFDs can work reliably even in tough conditions. It also gives the chemical industry a clear example of how to upgrade with smart technology.As China pushes for its "dual carbon" goals, the alumina industry needs to save energy and increase output at the same time. With its remote IoT connection and central monitoring system, the INVT GD880 VFD series can help factories manage equipment from start to end of life, supporting a move toward smarter, greener production.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.