Abstract: In sugar mills, steam boilers are used to produce steam during different stages of processing, including juice extraction, evaporation, clarification, crystallization, and sugar drying. High-pressure steam is produced by boilers and then passes via a turbine to generate electricity.

This article describes how INVT provided a cost-effective GD200A VFD solution for an Indian sugar mill's boiler application, helping the customer replace high-cost original drives while achieving stable performance and seamless integration with local and DCS control systems.

Keywords: GD200A, with local remote & DCS command.

1. Introduction

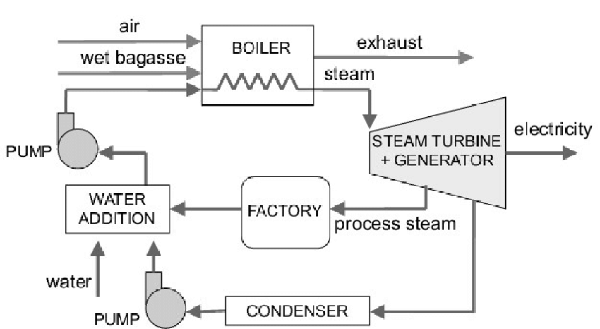

Schematic diagram of Boiler in Sugar plant

PLANT PROCEDURE:-

Boilers are used in sugar plants to generate steam for a variety of processes, including:

• Juice extraction: Steam is used to process the juice extracted from crushed sugarcane.

• Evaporation: Steam is used to evaporate water from syrup.

• Crystallization: Steam is used to heat vacuum pans in the crystallization stage.

• Sugar drying: Steam is used to dry sugar.

Customer Needs

Customer wants to use the VFD on Boiler Application.

• They want to use the cheaper product which fulfills their requirements as Danfoss.

• They need Cost- effective VFD as they get danfoss VFD in high price.

2. Project Information & Solution

* Project Information

Site Information: The boiler house section of a sugar factory.

* INVT Solution

| Application | Quantity | Inverter |

| BOILER | 1 | GD200A-400G-4 |

Features used in this solution

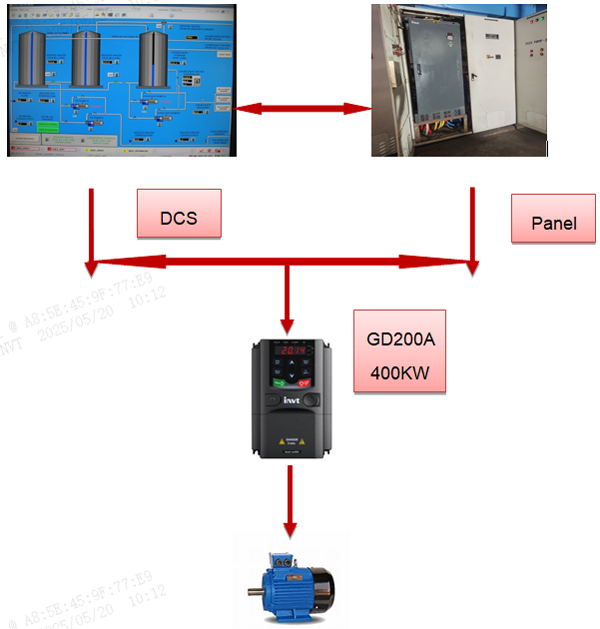

GD200A 400kw VFD used in Boiler Application;

• The motor control V/F we were using in this Application.

• That VFD is controllable from DCS or local command.

• Easy to operate the VFD from control panel as per wiring also checked the running load in VFD Display.

* System Configuration

* System Commissioning

3. Advantages and Customer benefits

Boilers have several advantages in sugar plants, including:

• Energy efficiency: High-pressure boilers are more energy efficient and can generate more electricity.

• Reduced waste: Boilers can reduce factory waste and can be used to produce fly ash bricks from the ash left over after burning bagasse.

• Co-generation: Boilers can be used in co-generation plants to produce enough electricity to power the factory.

• Biomass fuel: Biomass fuel boilers can burn both coal and biomass fuel, which can be reused and save money.

• Steam supply: Boilers can supply steam for different production processes in the sugar industry.

• Flexibility: Some boilers can be started and stopped at any time.

• Control: Boilers can be controlled using DCS systems.

• Energy management: Energy management systems can monitor and optimize boiler performance to reduce energy consumption and costs.

4. Conclusion

GD200A inverter is successfully used in boiler processes, and performance and stability all meet the process requirement.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.