Summary: This paper introduced INVT GD5000 medium voltage four quadrant VFD applied to tunnel hoister in tunneling work in China, to illustrate VFD transformation of the feasibility and the significant benefits.

Keyword: GD5000 medium voltage drive, AFE, four quadrant, tunnel hoister, energy saving;

1.Introduction

Tunnel hoister is a kind of mine elevator. It is mainly used in small and medium sized mines for transportation in auxiliary inclined shaft, inclined shaft elevator and track down. The incline shaft elevator and the muck car are similar to the freight car of train. The height and the volume are smaller.

In a wellhead there is a hoist machine, driven by the motor through the speed reducer drives the rotating drum, after the wire rope winding drum in a few circulars hang a muck car, under the driving of the motor will be full of muck from the train pulled up incline shaft. After completion of unloading the empty car inclined down the incline shaft by motor.

TIAN TAI Mountain tunnel project overall length is about 15.56km. It is the longest tunnel in the world. It is a part of express way from BAO JI city to PING KAN city.

The inclined shaft elevator motor and system parameters as below:

Table1: Inclined shaft elevator motor and system parameters

| Voltage | Power | Diameter of drum | Maximum lift speed | Altitude | Well depth |

| 10kV | 630kW | 3.3m | 5m/s | 1500m | 900m |

2.System Configuration

In view of the complex situation and the degree of difficulty of the TIANTAI Mountain tunnel engineering, and puts forward the scheme of improving INVT tunnel shaft new system consists of four quadrant, INVT high voltage inverter + three level medium voltage inverter and control system, application of four quadrant high voltage variable frequency drive + MV Frequency Low Frequency standby drive (for spare).

Among them, INVT high voltage four quadrant VFD using vector control, energy feedback operation, the speed closed-loop and current closed-loop control, the torque control dynamic response quickly, so as to obtain good control performance. The control system has good power saving effect, and improves the capacity of the grid and the utilization ratio of the electricity.

At the same time, the three level medium voltage inverter drive system adopts three level structure and with low input harmonic content. As a standby system, the low frequency system has good stability and good effect.

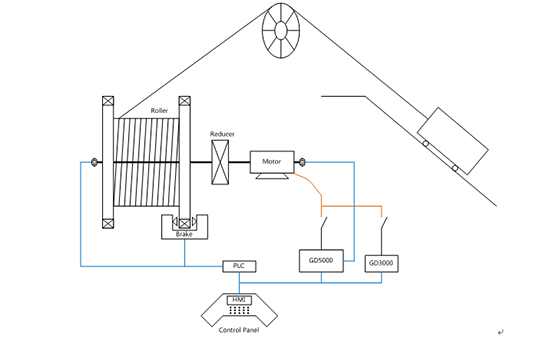

The whole system as below:

Fig.1 the whole system diagram

Fig. 1 is the schematic diagram of the main equipment of the lifting system. The lifting equipment used for tunnel construction in inclined shaft hoisting, transportation of goods, the difference of the design is the driving part of the high and medium pressure by the main program, the normal operation of high voltage motor driven by high voltage inverter. When the high voltage power supply fails, the medium voltage converter drives the high voltage motor at low speed to meet the requirements of the slow running of the goods under the emergency.

The high voltage four quadrant VFD parameters as below:

Table2: High voltage four quadrant VFD parameters

| VFD model | Voltage | Power | Current |

| GD5000-A1000-10-SR | 10kV | 800kW | 58A |

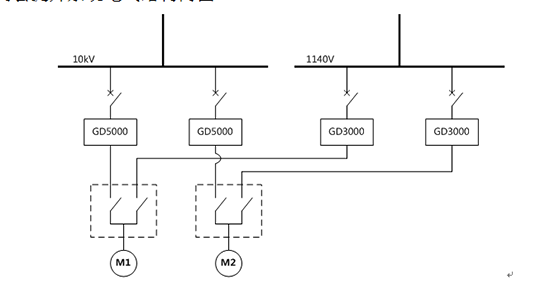

Fig.2 the VFD system simple electrical diagram

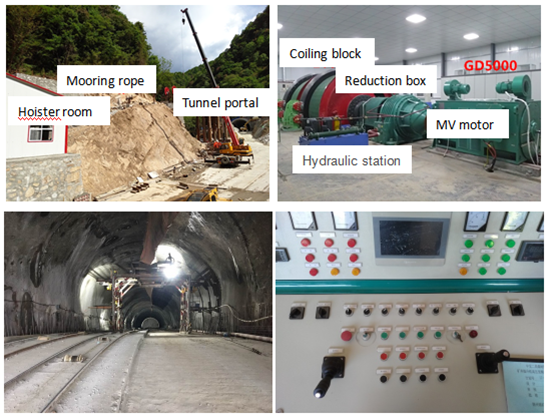

Fig.3 Pictures on the site

3.Application and Advantage

Compared to the previous scheme of inclined shaft hoisting using two quadrant converter, INVT provides high voltage vector four quadrant inverter drive + medium voltage variable frequency drive low running frequency scheme has obvious advantages, it is the real "green plan":

1) Compared to the ordinary two quadrant inverter, more energy saving;

INVT GD5000 four quadrant converter using the IGBT module as the rectifying device, to achieve a two-way flow of energy, without the need for any additional device which can be put into the power system operation to achieve the effect of energy saving and renewable energy.

2) Reduce grid power current harmonic, full load power factor is 1;

Because of the common inverter uses diode rectifier. The inverter will produce a large proportion of the harmonic components, cause serious pollution to the power grid, interfere with the normal work of other equipment, or even cause damage to other equipment. GD5000 series high voltage four quadrant vector inverter uses IGBT module as the rectifying device, generating PWM control pulse with high speed and high operation ability DSP, you can adjust the power factor, eliminate the harmonic pollution of power grid, so the inverter become truly "green products"

3) Use three level topology, the system is low input harmonic and system stability;

GD3000 series of medium voltage three level inverter has the advantages of simple structure, small volume, compared with the two level, with the same voltage level, the device can realize the voltage output of 2 times, the output of du/dt is reduced by half, the phase voltage output level to increase the number of output harmonics decreases, avoid end-user power factor and harmonic content exceed the standard caused by fines; It can reduce the motor common-mode voltage and power grid common-mode interference; and transmission capability, without considering the load motor position, reduce the user cost of the project.

Meanwhile INVT GD5000 series high voltage inverter has below significant advantages:

4) The whole system adopts multiple rectification / feedback to counteract the harmonic, and the current and voltage harmonics of the whole network side are in line with the national standard;

5) Each power unit of the whole machine is independently locked in phase, which can independently identify the phase change transformer ratio and phase difference of the phase-shifting transformer between primary and secondary side. The compatibility is good, and it is easy to realize the interchange between the power units;

6) The working state of the power unit (rectifier / feedback state) is controlled by the main control system according to the working state of the current motor, and good state consistency;

7) The power unit has a unique debugging interface, and it can conveniently monitor any unit working state through the photoelectric conversion device and the host computer software. It can quickly locate the unit fault and shorten the repair time.

4.Conclusion

The TIAN TAI Mountain tunnel project using the four-quadrant high voltage variable frequency drive INVT + low standby drag medium voltage variable frequency scheme can satisfy the operation efficiency of hoisting system and reasonable treatment of energy management, and meet the requirements of improving the stability and security of the system. According to the site feedback estimation, preliminary operation of energy-saving effect is about 15%-20%.

At the same time, the traditional control system consumes a large amount of slip power, speed is lower and consumption slip power is bigger in the control process. The use of INVT four quadrant frequency inverter scheme, can be completely avoided, is an energy efficient way to speed, energy saving is very significant, and achieved good economic benefit.

References

[1] GD5000 Series High-voltage Variable Frequency Speed Control System Manual. Shenzhen Invt Electric CO., LTD.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.