Abstract: This paper mainly introduces the application of INVT GD5000 medium-voltage inverters to vertical raw mill and describes detailed information involving the process of cement production, control structure and principle of electrical system, and the process of control system commissioning. The practical application shows good speed control performance and stability of INVT GD5000 11kV voltage inverters and it is worth promotion.

Keywords: GD5000, Medium voltage inverter, Vertical raw mill, Cement industry

1. Brief introduction

So far, INVT GD5000 series MV drives already widely used in Cement industry for applications like ID fan, FD fan, Boiler feed pump, pre-heat fan, and vertical raw mill and so on.

INVT GD5000 series MVD has the following features which suitable for this application:

a) Multi control mode V/f, SVC, VC, and compatible with both asynchronous and synchronous motor;

b) Full band rotation speed tracking, mast-slave control, excellent braking performance,

c) Excellent cell bypass and neutral point shifting function and bump-less synchronous switching.

d) Two quadrant and four quadrant drives are available.

e) Strong PC software and multiple extension cards: communication card, many kinds of PG card.

2. Cement process introduction

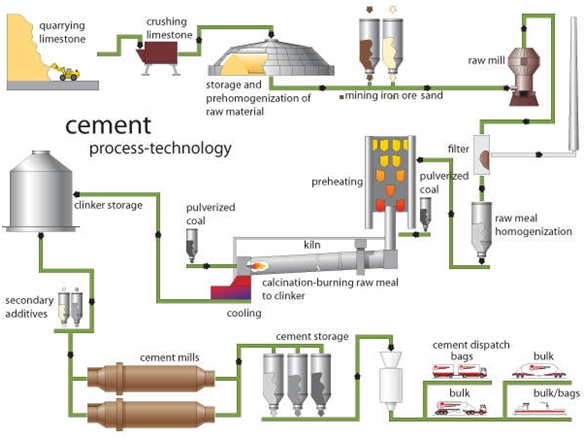

Cement process flow chart is as below:

And the cement process description is as follows:

1) Crushing and Pre-homogenization

Crush all the material like limestone, clay, iron ore and coal, and then pre-homogenization

2) Raw material preparation

Prepare the raw materials: fuel, clinker, mixture and gypsum

3) Raw material homogenizing

4) Preheating and calcinations

5) Formation of cement clinker

6) Cement grinding

Cement grinding is the last and power-consuming step in cement process, which will grind cement clinker to proper grain size.

7) Cement packaging

The cement is delivered in two ways of bag and bulk.

3.Project information and system solution

1) Vertical raw mill information

| No. | Items | Specifications |

| 1 | Model | CG NUWR8001 |

| 2 | Motor rated power | 3480kW |

| 3 | Rated speed | 992rpm |

| 4 | Rated voltage | 11kV |

| 5 | Rated current | 213A |

| 6 | Rated fequency | 50Hz |

| 7 | Efficiency | 96.5% |

2) Inverter selection

For vertical raw mill application, the main purpose to use inverter is soft-starting the motor and adjusting the speed, and it will also save energy. Considering high environment temperature, the MVD need to be de-rated, so the selection is as follows:

| No. | Items | Specifications |

| 1 | Model | GD5000-A5000-11 |

| 2 | Rated capacity | 5000kVA |

| 3 | Rated voltage | 11kV |

| 5 | Rated current | 262A |

| 7 | Copatable motor | 4000kW |

| 8 | Control mode | One-drive-two |

| 9 | Quantity | 1 set |

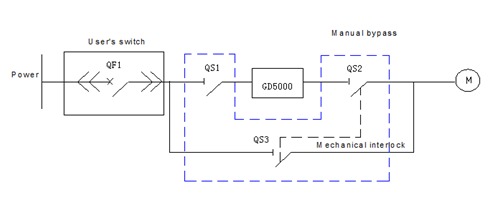

3) System diagram

After commissioning, the MVD runs smoothly and meets the requirement of speed adjusting.

4. Advantage

1) Soft starting function, increase the lifetime of motor.;

2) Reduce the maintenance time, reduce the loss of shutdown;

3) Achieve 54 pulses rectifier with phase shifting transform, lower harmonic pollution to the grid net;

4) Higher power factor, over 0.95, no need reactor power compensation device;

5) Easily control the MVD through DCS system by using Profibus communication.

5. Conclusion:

After using GD5000 series MVD, it’s very to control the mill speed, and the soft starting function makes the motor running smoothly, reduced the maintenance times and extend the motor and mill lift time significantly. The customer is very satisfied with INVT VFD.

Reference

[1] GD5000 Series High Voltage Inverter Instruction Manual,Shenzhen Invt Electric Co., Ltd.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.